When discussing the basic refrigeration cycle, we commonly use the terms superheat, subcooling, and saturation, but what do they mean and how do they help us troubleshoot a system?

Each of these terms refers to the state of the refrigerant. When a refrigerant exists in two phases (liquid and vapor), it is in a saturated state. The refrigerant composition could be 99% vapor/1% liquid or 99% liquid/1% vapor and the refrigerant would still be in a saturated state. One of the important properties of a saturated refrigerant is that there is a defined pressure/temperature relationship.

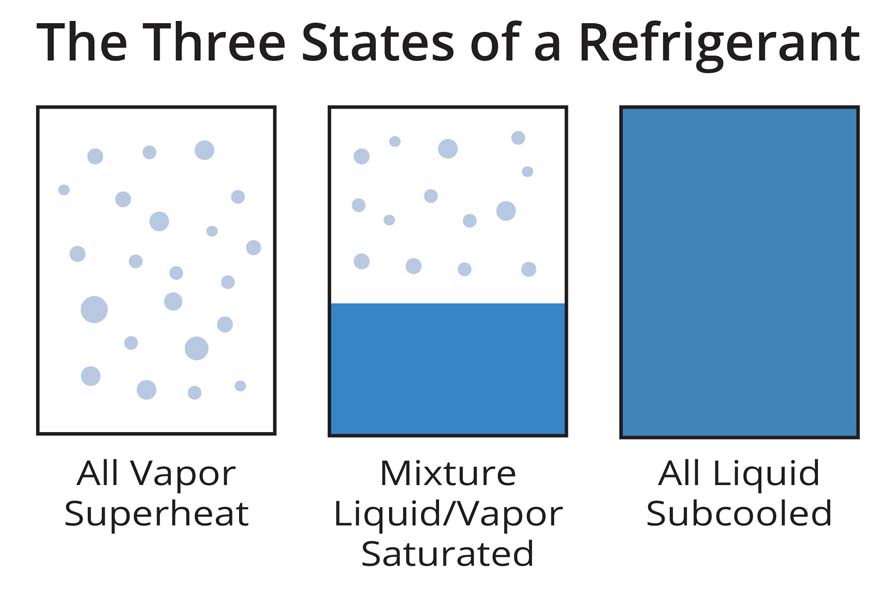

REFRIGERANT STATE: Superheat, subcooling, and saturation are all terms that refer to the state of the refrigerant. (Courtesy of Joe Marchese)

For single-component refrigerant at a given pressure — regardless of the percentage of the liquid to vapor — there is a single corresponding temperature. Unfortunately, for a blended refrigerant at a given pressure, its temperature will vary based on the percentage of liquid to vapor. For some refrigerants, this change is a few tenths of a degree, but for others, it could be as high as 8°F or more. Since the refrigerant is in a saturated state in both the evaporator and condenser, if we were to measure the refrigerant’s pressure in either of these coils, we could determine its temperature.

Knowing the temperature of the refrigerant can be a valuable parameter while troubleshooting a system issue. For systems using a blended refrigerant with a high temperature glide at a given pressure, we could only determine an approximate or average coil temperature, but it is still a valuable parameter to measure.

In a properly operating system, the refrigerant will be in an all-vapor state as it travels from the last section of the evaporator through the suction line, through the compressor and discharge line, and into the first section of the condenser. When a refrigerant is in an all-vapor state, it is said to be superheated. Any additional heat energy added to the refrigerant will cause its temperature to increase. Measuring this increase in temperature is another valuable parameter.

At any given pressure, we can measure the refrigerant’s vapor temperature and compare it to its saturation temperature. The increase in temperature above saturation is described as the refrigerant’s superheat value. For example, at 18.42 psig, R-134a has a saturation temperature of 20°F. If its measured temperature is 30°F, the refrigerant is said to be superheated by 10°F.

One useful area to measure the refrigerant’s superheated value is at the exit of the evaporator. Measuring this value can help us understand how effective the evaporator is in removing heat energy from the air or water passing over it. If the refrigerant’s superheat value is much higher than designed, the evaporator is starved for refrigerant. This means either there is not enough refrigerant entering the evaporator or the heat load placed on the evaporator is too high. If the refrigerant’s superheat value is too low or at saturation, the evaporator is flooded, meaning there is too much refrigerant entering the evaporator or the heat load is too low.

Measuring the refrigerant superheat value leaving the evaporator may not allow you to find the root cause of the system failure, but coupled with other system measurements, it will allow you to make the proper diagnosis.

As the refrigerant leaves the last section of the condenser and travels through the liquid line to the metering device, it will be in an all-liquid state. 'Subcooled is the term used to describe this state. When the refrigerant is in a subcooled state, any further heat energy removed will cause its temperature to decrease. Measuring this decrease in temperature is another valuable parameter. At a given pressure, we can measure the refrigerant’s liquid temperature and compare it to its saturation temperature. For example, at 124.1 psig, R-134a has a saturation temperature of 100°F. If its measured temperature is 90°F, the refrigerant is said to be subcooled by 10°F.

One useful area to measure the refrigerant’s subcooled value is at the exit of the condenser. As the refrigerant travels through the last section of the condenser, it should be in an all-liquid state (subcooled). As the air or water crosses over this section of the condenser, any heat energy removed from the refrigerant will reduce its temperature. If the refrigerant’s subcooled value is much higher than designed, the condenser is flooded with refrigerant. If the refrigerant’s subcooled value is too low or at saturation, the condenser is starved for refrigerant. Again, this alone may not allow you to find the root cause of the system failure, but coupled with other system measurements, it will allow you to better diagnose a system issue.

Report Abusive Comment