As the U.S. moves toward electrification, heat pumps are becoming more popular. Thanks to generous tax credits and rebates being offered by utilities, as well as state and federal governments, sales of heat pumps will likely increase exponentially in the coming years, so it’s important to understand the wide range of equipment that is currently available.

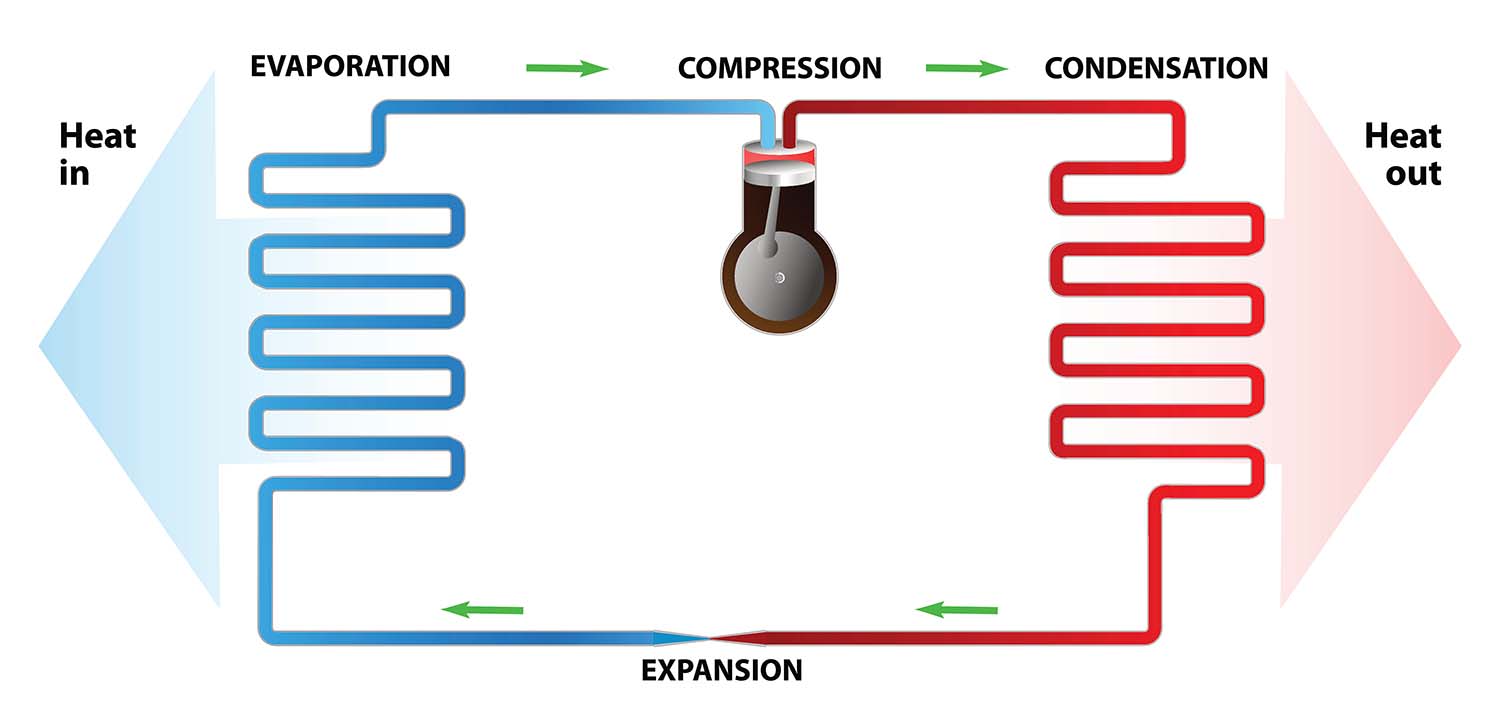

While there are many different types of heat pumps, they all operate in a similar fashion. Essentially, the heat pump uses a refrigerant to transfer heat to and from the living space: in the summer, it acts as an air conditioner, and in the winter, it reverses the refrigerant flow and becomes a heating unit. The main difference between heat pumps is how they extract heat, which can be from the air, water, or ground.

Associate director of cooling product management

Carrier

Air-Source Heat Pump (Ducted)

How it works: The most common type of heat pump in the U.S. is the ducted air-source heat pump and as its name implies, it uses the surrounding air to heat and cool a building. In the heating mode, the heat pump extracts heat from the outside air and transfers it indoors, where it is distributed through a home’s existing ductwork. In the cooling mode, the process reverses and the heat pump extracts heat from inside the home and deposits it outside.

Click graphic to enlarge

AIR COOLED: Ducted air-source heat pumps use the surrounding air to heat and cool a building. In heating mode, the heat pump extracts heat from the outside air and transfers it indoors; in the cooling mode, the process reverses. (Courtesy of Carrier)

“Air-source heat pumps are very versatile and can be installed in new construction or retrofit applications,” said Heidi Gehring, associate director of cooling product management, Carrier, who also provided the information that follows.

HP VERSATILITY: Air-source heat pumps are very versatile and can be installed in new construction or retrofit applications. (Courtesy of Carrier)

Configurations: Most heat pumps are split systems, with one indoor and one outdoor coil, using supply and return ducts to connect to the central fan inside. Packaged systems have both coils and the fan outdoors, moving conditioned air through ductwork that passes through a roof or wall.”

Benefits: Heat pumps are versatile in creating indoor comfort — they can provide heat in winter and also act as air conditioners, cooling and removing humidity, in summer. Depending on the type of heat pump and application, they can be used in virtually any climate. Heat pumps are also dual-source capable, meaning they can be combined with a gas furnace to maintain the home’s unique heating needs while still benefiting from the heat pump’s energy efficiency.

Considerations: Historically, heat pumps faced challenges operating at maximum efficiency as temperatures dropped and people felt cold air blowing from the register, but this is no longer the case, as heat pump technology has advanced, and research and development activities continue to improve performance in colder climates.

That said, as outdoor temperature decreases, traditional heat pumps are able to provide less heating capacity, so they have to run longer to condition a space. Many heat pump models today can heat effectively at 5°F and continue to work well below 0°F, but do so less efficiently. In colder climates, heat pumps may be equipped with supplemental electric resistance heat to help warm the living space when the system cannot maintain the space temperature due to low outdoor air temperature. Or, the heat pump can be paired with a gas furnace, which can offer greater energy savings.

Energy efficiency: Because they run on electricity, air-source heat pumps are more energy-efficient than many other home heating solutions. Starting January 1, 2023, all heat pumps must be rated at 14.3 SEER2 and 7.5 HSPF2, per the Department of Energy’s (DOE’s) new efficiency standards.

Cold Climate Heat Pump

How it works: A cold climate heat pump (CCHP) works in a similar fashion to a traditional, ducted, air-source heat pump; however, it is designed to provide higher heat capacities at colder outdoor temperatures, so less backup heat is needed, said Tim Brizendine, director of product management at Lennox International Inc., who also provided the information that follows.

COLD CLIMATE: A cold climate heat pump works in a similar fashion to a ducted air-source heat pump; however, it is designed to provide higher heat capacities at colder outdoor temperatures. (Courtesy of Lennox)

Most CCHPs utilize a variable-speed compressor and inverter so that they can speed up the compressor as it gets colder outside to maintain or increase the heat capacity of the system. They are best suited for colder climates found in the northern U.S. states and Canada and can be used for retrofit or new construction.

Configurations: A CCHP can be designed as a split system or a package unit; however, for residential applications, most of the systems installed in colder climates are split systems. They can be installed with a traditional air handler with backup heat strips or with a gas furnace as a dual fuel system.

Benefits: CCHPs provide heat at colder temperatures and offer an efficient, environmentally friendly alternative to gas furnaces. They can be more than twice as efficient as using backup electric resistance heating and can also provide warmer supply air temperatures than a traditional heat pump, providing greater levels of comfort.

Considerations: A CCHP is still a heat pump, so it is affected by the outdoor conditions as to what heating capacity and efficiency it can provide. While better than a traditional heat pump, there are limitations, and they still require some backup heat sources for extreme conditions and defrost operation.

Energy efficiency: Most CCHPs utilize inverter-driven variable-speed compressors starting in the 18+ SEER (17+ SEER2), 9.6+ HSPF (8+ HSPF2) seasonal efficiency range; however, CCHPs offer better heating capacity and efficiency at colder temperatures. Most CCHP requirements are for a coefficient of performance (COP) — heating efficiency of the heat pump at the stated condition (indoor and outdoor dry and wet bulb temperature) — at 5°F of at least 1.8. There are many systems available on the market today that meet these requirements.

Hybrid Heat Pump

How it works: A hybrid system is not that much different than a typical air-source heat pump system. The only difference is that rather than having electric heating strips as the backup heat source, there is a gas furnace, said Mark Woodruff, senior product manager of ducted outdoor equipment at Trane Technologies, who also provided the information that follows.

HYBRID SYSTEM: A hybrid system usually consists of an air-source heat pump system and a gas furnace, which is the backup heat source. (Courtesy of Trane)

Hybrid systems work in any climate and for both retrofit and new construction. During hot summer weather, the heat pump works like a central air conditioner, transferring hot air out of the home. In moderately cold temperatures during the spring and fall, a heat pump provides adequate heating; however, as outdoor temperatures dip further, the average heat pump decreases in heating capacity and efficiency. When temperatures get below 40°F, the gas furnace takes over to quickly heat the house. The system is designed to automatically switch between the heat pump and furnace, depending on the home’s temperature conditions.

“Much like a hybrid car will run on electricity as often as possible and will switch over to gas engine when needed, a hybrid heat pump will run the electric heat pump as often as possible and will switch over to the gas furnace when needed,” said Woodruff.

Configurations: A hybrid heating system can consist of just about any combination of air-source or geothermal heat pump with a gas furnace.

Benefits: Existing homes in colder regions of the country often use gas furnaces plus an air conditioner and the cost to convert to a traditional all-electric heat pump system can be very expensive. Hybrid systems offer those homeowners a way to adopt a heat pump and reduce their carbon footprint at a much lower total cost, while keeping the safety net of a gas furnace for extremely cold days/weeks/months. In addition, if the power goes out and the homeowner has a generator, a hybrid system can switch to the backup gas furnace and heat the home using very low amounts of power.

Considerations: While the term “hybrid heat pump” may not be familiar to homeowners, these systems have been around for a very long time (decades). The technology is not new and is very well established and reliable. Another common name for a hybrid heat pump is “dual fuel,” which is an older name that originated from the description that these types of systems heat the home using a combination of electricity and gas.

Energy efficiency: There is no performance difference between a traditional heat pump and a hybrid system. Homeowners have a range of options that span from a top-of-the-line, variable-speed, highly efficient system all the way down to a very low-cost, minimum efficiency, entry level system. Most modern thermostats have the capability to run a hybrid system.

Mini-Split Heat Pump (Ductless/Ducted)

How it works: Ductless mini-split heat pumps operate in the same way as traditional air-source heat pumps, except instead of using a home’s existing ductwork to distribute conditioned air, they use indoor units placed in the living space. The indoor unit of a ductless mini split system is generally referred to as a wall-mounted unit.

There are also ducted mini-split heat pumps that use a home’s existing ductwork to deliver conditioned air to multiple rooms or even a whole floor. The indoor unit of a ducted mini-split unit is generally referred to as a ceiling ducted unit.

“Traditionally, mini splits have symbolized a small capacity split system with a wall-mount indoor unit. The evolution of the product globally and in the U.S. has led to development of many other types of indoor units including, ceiling cassettes (e.g., one-way, two-way, four-way), floor consoles, slim ducted, horizontal ducted, and even a U.S.-type air handler,” said Terry Frisenda, construction sales manager at LG Electronics U.S.A. Inc., who also provided the information below.

Configurations: Mini splits are available as single- or multizone systems. In a multizone system, the outdoor unit can operate more than one indoor unit. In addition, the multizone outdoor unit has dedicated electronic expansion valves for each connected indoor unit and each indoor unit communicates with the outdoor unit independently to satisfy its unique set point. Indoor units cannot provide heating and cooling at the same time, as all indoor units operate only in the same mode if a heat pump is used. It is possible to provide simultaneous heating and cooling when using a heat recovery outdoor unit.

Benefits: Ductless/ducted mini-split systems can be used in new construction, as well as retrofit. They are particularly useful in older homes or buildings that have limited access, historic value, and/or challenging installation conditions. Mini-split heat pumps have small electrical requirements and high efficiencies. They are also quiet, offer conditioning for problematic areas, and are zero lot line friendly.

Considerations: In some colder climates, mini splits may benefit from the addition of an auxiliary heater, but most will never see it come on if the outdoor unit is sized correctly. If needed, some ducted indoor units can either add a factory auxiliary heat kit or a third-party heat kit, depending on the style. Outdoor units are available that are rated at 100% capacity at 5°F and continue to operate at nearly 70% capacity at -13°F.

Energy efficiency: Entry level ductless systems often start at 17 SEER and 13.5 HSPF and increase from there. It’s important to note that as the inverter compressor satisfies the set point, it changes its electrical Hertz and operates the compressor and related components just enough to maintain temperature without wasteful cycling like traditional systems.

VRF Systems

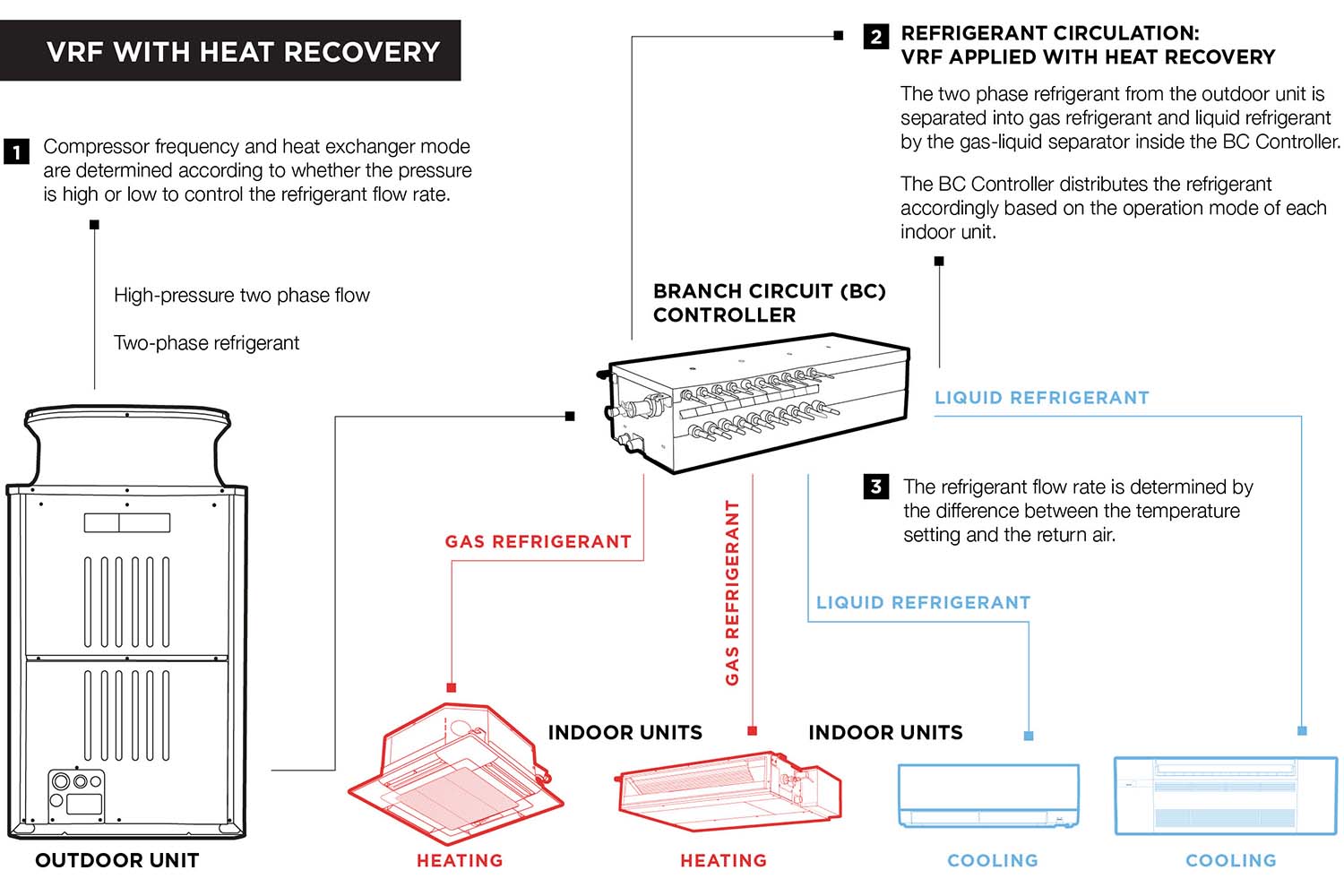

How it works: Variable refrigerant flow (VRF) technology provides energy-efficient, zone-by-zone comfort control for occupants, using refrigerant to capture and repurpose existing heat from the environment, said Tom Dowling, vice president of commercial business at Mitsubishi Electric Trane HVAC US LLC (METUS), who also provided the information that follows.

Click graphic to enlarge

SIMULTANEOUS COMFORT: VRF systems with heat recovery provide simultaneous heating and cooling, meaning some zones can operate in heating mode while other zones are in cooling mode. (Courtesy of Mitsubishi Electric Trane HVAC US)

Air-source VRF systems draw heat from outdoor ambient air, while water-source systems draw heat from a nearby water source such as a geothermal well. During cooling, VRF heat pump systems reject heat into the outdoor air or water source. VRF systems with heat recovery provide simultaneous heating and cooling, meaning some zones can operate in heating mode while other zones are in cooling mode.

If applied according to best practices and consideration for winter weather, modern VRF systems can serve as the primary heating and cooling system in climate zones 1 through 6. Some systems feature additional heating capabilities, and with some creative applications of the outdoor unit, plus wind and snow guard accessories, VRF systems offer cold-climate capabilities beyond those of conventional heat pump systems, even without auxiliary heat.

DESIGN FLEXIBILITY: The City Multi N-Generation VRF delivers application and design flexibility, along with sustainability and energy efficiency. (Courtesy of Mitsubishi Electric Trane HVAC US)

Configurations: Supported by integrated controls and sensors, VRF systems heat and cool by transferring conditioned refrigerant between each zone’s indoor unit(s) and an outdoor unit. Up to 50 indoor units can be connected to a single outdoor unit. There are many styles of indoor units, including ductless and ducted designs. VRF systems modulate the flow of refrigerant, so the system only uses the precise amount of energy needed to meet each zone’s conditioning requirements.

Benefits: VRF systems are suited for every climate and for any commercial or light commercial application, both retrofit and new construction. Another key benefit is complete zone control, so users only heat and cool the areas needing conditioning, which can result in operational savings. Due in part to their design flexibility, VRF systems are ideal for diverse applications, from modern designs to historic renovations.

Considerations: Upfront cost may be a consideration, but a true comprehensive comparison of upfront HVAC costs includes more than equipment. For example, the compact outdoor units reduce the need for special rigging with cranes or lifts and won’t require additional roof structure reinforcements. In addition, there are usually savings achieved through less design time, easier installation, and lower labor costs.

Energy efficiency: VRF systems are up to 40% more energy-efficient than conventional, fixed-capacity HVAC equipment. Most of these savings occur during partial-load conditions, as the VRF system’s inverter compressors modulate the electrical current's voltage and frequency, so the compressor motor can ramp up and slow down to achieve optimal refrigerant flow and pressure. This enables the VRF system to vary capacity and energy use to match real-time heating or cooling loads. VRF systems regularly achieve COPs of 3 and higher, meaning they can deliver much more heat energy than they consume in watts.

Water-Source Heat Pump (Geothermal)

LOOP CONNECTION: A water-source heat pump is connected to a loop, which provides warm or cold water to the indoor unit. (Courtesy of Bosch Thermotechnology)

How it works: A water-source heat pump (WSHP), also called a geothermal heat pump, has a relatively simple setup that functions just like air-source heat pumps to harness the difference in temperature between two sources, but instead of air, it uses water, said Ian McIver, product manager at Bosch Thermotechnology, who also provided the information that follows.

A typical system consists of an indoor unit with a fan, air coil, compressor, and water coil. The heat pump is connected to a loop, which provides warm or cold water to the indoor unit. The heat pump uses refrigerant to transfer heat from the water source, either absorbing energy to heat the space or dispersing heat to cool the space. In cooling mode, warm air is drawn in across the air coil, where it’s cooled and then distributed throughout the space. In heating mode, cold air is drawn in across the air coil where it is heated and then distributed throughout the space.

“WSHPs are some of the most efficient and reliable HVAC systems on the market,” said McIver.

Configurations: WSHPs are available in a variety of configurations and sizes and can be placed in several areas within a home or building. Configurations include split systems or single cabinet package systems and sizes scale from ½- to 30-ton sizes. There are a variety of options to select on WSHPs including capacity, voltage, water coil material, return air direction and many others. They can be set up for geothermal closed-circuit or open-well loops, or for boiler/tower loop systems.

CLOSET INSTALLATION: WSHPs are available in a variety of configurations and sizes and can be placed in several areas within a home or building, including a closet. (Courtesy of Bosch Thermotechnology)

There are two main categories for WSHP systems, water-to-water and water-to-air. Water-to-water heat pumps are used to heat and cool water itself and can also provide potable hot water; space, pool, and radiant floor heating; and snow melt for walkways and driveways. Water-to-air systems heat and cool air for forced air ducted systems. They can also include a desuperheater, which is a secondary heat exchanger that enables the heat pump to heat domestic hot water.

Benefits: WSHPs are highly efficient, which can reduce operating costs. These systems are typically easy to maintain, long lasting, and don’t rely on fossil fuels to function. WSHP systems do not rely on the air temperature of the environment, but rather the temperature of the water they are provided. This allows them to function efficiently in almost any climate, regardless of outside air temperature, as long as they are receiving water at an appropriate temperature.

Considerations: WSHPs can have higher installation costs, but that can be offset by a reduction in operating costs. Geothermal heat pumps that achieve Energy Star efficiencies currently qualify for federal rebates and incentives, which can help offset their cost. Depending on how the system is designed, additional heating sources, such as a gas furnace, may be utilized to meet the heating requirements.

Energy efficiency: To meet Energy Star requirements, the minimum efficiencies for a geothermal heat pump are an EER of 17.1 and a COP of 3.6 (closed loop water-to-air). Much of the geothermal equipment available on the market surpasses those targets and is capable of reaching above 30 EER and 5 COP.

Ground-Source Heat Pump (Geothermal)

How it works: Ground-source heat pump (GSHP) systems are similar to WSHPs, except instead of water, GSHPs rely on the constant temperature of the earth beneath the frostline to transfer heat. GSHPs transfer heat stored in the earth into a building during the winter and transfer it out of the building and back into the ground during the summer. The ground essentially acts as a heat source in winter and a heat sink in summer, according to the Department of Energy, which provided some of the information that follows.

A typical GSHP consists of connected pipes, commonly called a loop, which are buried in the ground near the building to be conditioned. The loop can be buried either vertically or horizontally and circulates a fluid (water, or a mixture of water and antifreeze) that absorbs heat from, or transfers heat to, the surrounding soil. In heating mode, the heat pump removes the heat from the fluid in the loop, concentrates it, and then transfers it to the building. For cooling, the process is reversed. Conventional ductwork is generally used to distribute heated or cooled air throughout the building.

Configurations: Similar to WSHPs, GSHP configurations can include split systems or single cabinet package systems.

Benefits: Compared to traditional air-source heat pumps, GSHPs are quieter, last longer, need little maintenance, and do not depend on the temperature of the outside air.

Considerations: The initial cost of a GSHP is usually much higher than traditional air-source heat pumps, due to the high front-end cost of installing a ground loop. The availability of trained and experienced contractors to properly design and install GSHPs can also be limited.

Energy efficiency: GSHPs can reduce energy consumption by approximately 25% to 50% compared to air -source heat pump systems, as well as reach high efficiencies (300% to 600%) on the coldest winter night. Average EER ratings usually range between 20 and 30.

Air-to-Water Heat Pump

How it works: An air-to-water heat pump transfers thermal energy from the outside air to water, which is then used to heat or cool interior spaces via radiant floors/ceilings/walls, fan coils, or other hydronic-based terminal units. Systems can also heat domestic water, which is stored in an insulated indirect tank, said Mark Chaffee, vice president of governmental affairs and commercial and industrial product management at Taco Comfort Solutions, who also provided the following information:

AIR TO WATER: Chester Birchwood, owner of HVAC Kings LLC in New York City, programs his customer’s new System M air-to-water heat pump. The indoor unit is one of two parts to the system; the condensing unit is located in the backyard. (Courtesy of Taco)

Systems consist of an air-to-water heat pump outdoor unit and a hydrobox indoor unit. The outdoor portion of the heat pump can feature inverter technology and a variable-speed fan and quiet operation, while the hydrobox contains an integrated buffer tank, wiring hub, user interface, and a high-efficiency, dual-ECM pump piping module. The appliance-like design provides can reduce installation time by 50%.

“Air-to-water heat pumps are an ideal fit for homeowners and/or installers who seek to reduce their carbon footprint, as it doesn’t create CO2, with a complete packaged system that’s simple to install and operate,” said Chaffee.

Configurations: The monobloc configuration keeps all components of the heat pump, including the factory-sealed R-410A refrigerant, within a single outdoor enclosure. Two pipes carry either water, or a mixture of water and antifreeze, between the outdoor unit and the interior hydrobox and the distribution portions of the overall HVAC system.

Benefits: Air-to-water heat pumps can provide heating, cooling, and domestic hot water from a single complete, turnkey system. The technology is designed specifically for a low carbon society and built with the knowledge that water is the most efficient and natural energy transfer medium on the planet.

Considerations: Air-to-water heat pumps — like most heat pumps — work at their highest efficiency in moderate climates. The system extracts heat from ambient air at temperatures down to -7°F, and at those temperatures, still operate at efficiencies higher than the most efficient furnace. In climates where prolonged operation is below zero, supplemental heat sources should be part of the overall mechanical design. This may include electric resistance heat or a small boiler or wood stove to cover extreme operating conditions.

Energy efficiency: Systems can provide efficiencies of over 4 COP, meaning greater than 400%.

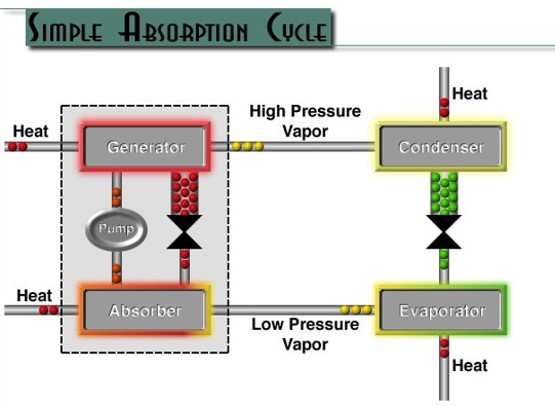

Gas Absorption Heat Pump

How it works: In an absorption heat pump, the fluid used in the sealed system is a solution of water and ammonia, with ammonia being the refrigerant and water being the absorbent. Through a thermal dynamic process, the refrigerant either picks up heat by evaporating at a low temperature and pressure (cooling) or gives up heat by condensing at a higher temperature and pressure (heating). The system provides a chilled water line or hot water line. There are no compressors or engines, and gas is the primary fuel used to begin the thermal process, said Bert Warner, national sales and business development manager at Robur Corp., who also provided the information that follows.

Click graphic to enlarge

NO COMPRESSORS: There are no compressors or engines in an absorption heat pump, and gas is the primary fuel used to begin the thermal process. (Courtesy of Robur)

“These heat pumps fit most climates and are rated down to -20°F,” he said. “They can be installed in both retrofit and new applications.”

ABSORPTION HP: In an absorption HP, the refrigerant either picks up heat by evaporating at a low temperature and pressure (cooling) or gives up heat by condensing at a higher temperature and pressure (heating). (Courtesy of Robur)

Configurations: These systems can be used with a variety of delivery methods, including fan coils, air handlers, ceiling cassettes, high wall units, chilled beams, and radiant floors.

Benefits: Absorption heat pumps are very quiet and offer ultra-efficient gas heating (129% nominal efficiency), much lower electrical power consumption, and savings in operational costs. The units are reliable and durable and feature modular construction.

Considerations: Being rated down to -20°F, most applications do not need a backup system; however, if the units needed to operate below these ratings for extended periods of time, some sort of backup system may be required. In heat pump-only systems that require water temperatures above 140°F, preheat or an integrated system application is necessary.

Energy efficiency: Gas absorption heat pumps are measured using COP, and using this metric, efficiency numbers are more than 100%.

Director of product management

Lennox International Inc.

As can be seen here, there are many different types of heat pumps that can suit just about any application. As Brizendine noted, heat pumps have come a long way over the past decade or two and offer greater capacities, efficiencies, and comfort than ever before.

“Some contractors and consumers may have a negative view of heat pumps due to experiences they have had in the past,” he said. “But many of the shortcomings in heat pumps have been addressed, and future regulations will drive heat pump usage. I would encourage anyone who is not comfortable with selling and installing heat pumps to get educated and trained on these systems, so they are ready for the future.”

Webinar: Learn the Benefits of the 9 Types of HVAC Heat Pumps

In this webinar series, we will examine each of the 9 different types of heat pumps and:

- Discover the benefits of each type of heat pump.

- Examine the energy-efficiency of the different heat pumps.

- Learn about the tax credits for each heat pump.

- Analyze the proper installation practice of each heat pump.