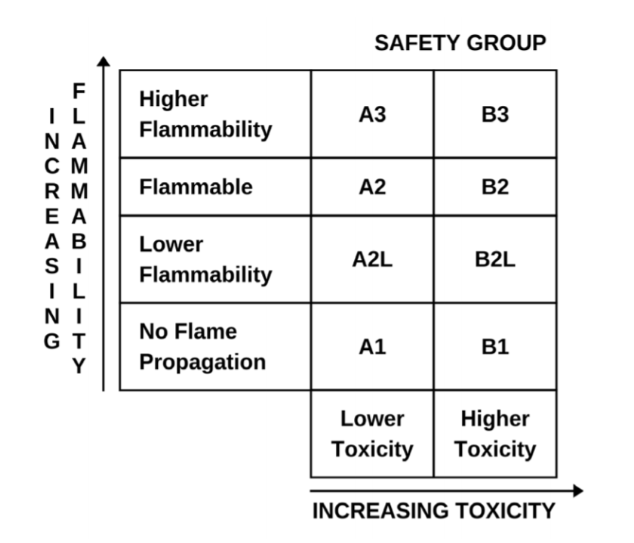

The HVACR industry is in the process of researching new low-GWP refrigerants and refrigerant blends that can be incorporated into refrigeration and air conditioning systems. ASHRAE Standard 34 classifies some of these new refrigerant blends as A2L, meaning they are lower flammability with lower toxicity (see Table 1).

TABLE 1: ASHRAE Safety Classification of Refrigerants.

Many of these new blends are 400 Series, which means they have a temperature glide when evaporating and condensing. This article will cover how to calculate temperature glide, superheat, subcooling, and average evaporator temperatures for refrigerant blends that have temperature glide.

Temperature Glide

Many refrigerant blends have temperature glide when they change phase in both the condenser and evaporator. In the evaporator, the refrigerant changes phase (evaporates) from a liquid to a vapor, while in the condenser, the refrigerant changes phase (condenses) from a vapor to a liquid.

Some refrigerant blends exhibit temperature glide, because there is more than one molecule present in their blend makeup. As these refrigerant blends phase change (evaporate and condense), there is a change in their composition by preferential evaporation or condensation of the more or less volatile component in the blend. This process is referred to as blend fractionation.

The total temperature glide of a refrigerant blend is defined as the temperature difference between the saturated vapor temperature and the saturated liquid temperature at a constant pressure. Another definition is the temperature difference between the starting and ending temperature of a refrigerant phase change within a system at a constant pressure. Here are some examples of total temperature glide magnitudes:

| Suction (evaporating) pressure | 70 psig |

| Head (condensing) pressure | 180 psig |

| Evaporator outlet temperature | 56°F |

| Condenser outlet temperature | 74°F |

When dealing with refrigerant blends that have temperature glide, when the liquid refrigerant boils in the evaporator, the composition of the liquid and vapor phases are different. The liquid phase becomes richer in the higher boiling point component as the low boiling point components boil off into the vapor phase. In the condenser, as the refrigerant vapor continues to condense, the vapor phase becomes richer in the low boiling point components as the higher boiling point components of the refrigerant blend condense to a liquid. So, again, the composition of the liquid and vapor phases is different as condensation takes place.

Refrigerant blends can have two, three, four, or more refrigerants making up the composition of the blend. For example:

- R-410A consists of two refrigerants: R-32/R-125;

- R-404A consists of three refrigerants: R-125/R-143a/R-134a;

- R-427A consists of four refrigerants: R-32/R-125/R-143a/R-134a;

- R-438A consists of five refrigerants: R-32/R-125/R-134a/R-600/R-601a;

- R-454A consists of two refrigerants: R-32/R-1234yf;

- R-454B consists of two refrigerants: R-32/R-1234yf;

- R-454C consists of two refrigerants: R-32/R-1234yf; and

- R-455A consists of three refrigerants: R-32/R-1234yf/CO2.

Refrigerant blends that exhibit temperature glide are often referred to as zeotropic refrigerant blends or zeotropes. They are represented by the 400 Series blends, such as R-401A, R-407C, R-409A, R-427A, R-438A, R-454A, R-454B, R-454C, and R-455A to name a few.

Refrigerant blends that do not exhibit temperature glide, or their temperature glides are negligible, are referred to as azeotropic blends and are represented by the 500 Series blends, such as R-500, R-502, and R-507.

Often, refrigerant blends exhibit a small amount of temperature glide when they phase change, and these are referred to as near-azeotropic refrigerant blends. Examples of these blends are R-410A, R-404A, as well as many others.

As noted earlier, as azeotropic and near-azeotropic refrigerant blends phase change through the length of the evaporator and/or condenser heat exchanger, there will be a change in their composition by preferential evaporation or condensation of the more or less volatile component in the blend. The amount of temperature glide depends on the refrigerant blend’s makeup and the system design. System performance, design, and service conditions must be evaluated when incorporating, or retrofitting with, a zeotropic or near-azeotropic refrigerant blend.

There are also single component refrigerants, which have only one molecule in their structure, so they evaporate and condense at one constant temperature for a given pressure. This means that their saturated liquid temperature and saturated vapor temperature are the same for one given pressure. In both the evaporator and the condenser, both liquid and vapor exist in equilibrium, so as a result, the temperature glide of a single component refrigerant is zero. Examples of these single component refrigerants include R-22, R-32, R-123, R-125, R-134a, and R-143a.

Calculating Glide

In the following example, R-407C will be used to illustrate the refrigerant total temperature glide, effective temperature glide, fractionation, superheat, subcooling, and average evaporator and condenser temperatures using a refrigerant blend’s pressure/temperature chart. R-407C is a zeotropic refrigerant blend consisting of three HFC refrigerants: R-32 (23%), R-125 (25%), and R-134a (52%).

The following given conditions are for a summer air conditioning application:

| Suction (evaporating) pressure | 70 psig |

| Head (condensing) pressure | 180 psig |

| Evaporator outlet temperature | 56°F |

| Condenser outlet temperature | 74°F |

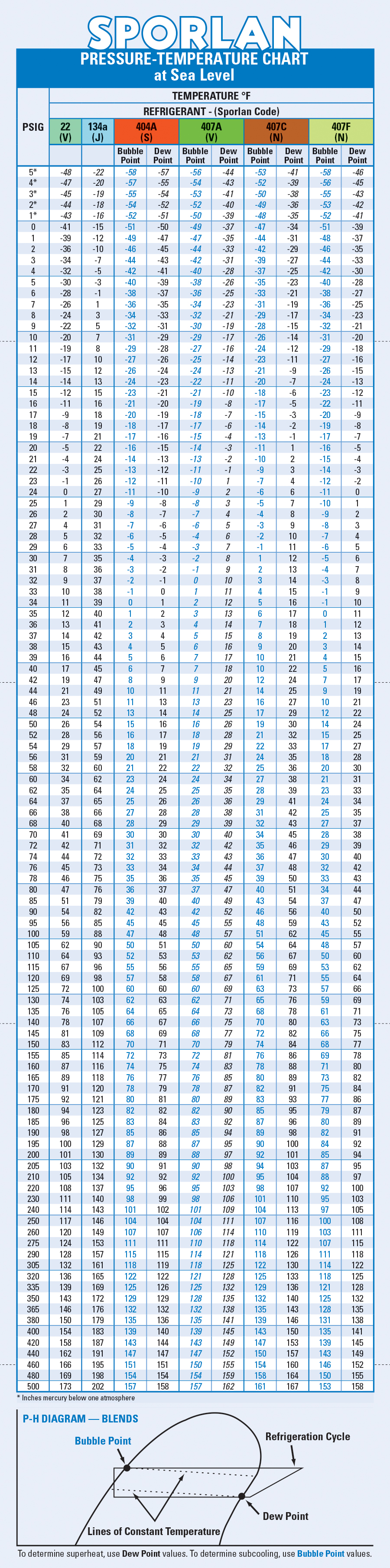

An examination of the pressure/temperature chart in Table 2 clearly shows that for a suction (evaporating) pressure of 70 psig, the saturated liquid temperature is 34°F and the saturated vapor temperature is 45°F. This would give the evaporator a total temperature glide of 11°F (45°F – 34°F). The saturated vapor temperature of 45°F is referred to as the dew point temperature, and the saturated liquid temperature of 34°F is referred to as the bubble point temperature.

TABLE 2: Pressure-temperature chart. (Courtesy of Sporlan Division, Parker Hannifin

Click table to enlarge

Since superheat is defined as any sensible heat gained after the saturated vapor point in the evaporator, the evaporator superheat would be 11°F (56°F – 45°F), where 56°F is the evaporator outlet temperature and 45°F is the saturated vapor (dew point) temperature . When HVACR service technicians are calculating superheat values, they must always use the dew point values from the pressure/temperature chart shown in Table 2. This same chart instructs the service technician to use bubble point values when determining subcooling.

As liquid refrigerant starts to vaporize, some of the liquid vaporizes inside the metering device and not in the evaporator. The refrigerant actually enters the evaporator as a mixture of liquid and vapor, not as a saturated liquid. This means that the effective temperature glide would be less than the total temperature glide.

For a typical zeotropic refrigerant blend entering the evaporator with a quality or percent vapor of 25% to 35%, a typical effective evaporator temperature glide would be about 70% to 75% of the total temperature glide difference between the saturated liquid and vapor temperatures at a given pressure. In the example above, this would mean that the effective temperature glide of the evaporator would be about 8.25°F (75% of 11°F). Effective temperature glide is usually used in engineering design conditions and not in superheat or subcooling calculations for service technicians.

Since subcooling refers to a liquid and is defined as any sensible heat lost after the saturated liquid point in the condenser, the condenser subcooling would be 11°F (85°F – 74°F), where 74°F is the condenser outlet temperature and 85°F is the saturated liquid (bubble point) temperature corresponding to the 180 psig head (condensing) pressure. As mentioned earlier, the P/T chart in Table 2 instructs the service technician to use bubble point values when determining subcooling.

The average evaporator temperature occurs at the midpoint of the effective temperature glide. Since the effective temperature glide is 8.25°F, the average evaporator temperature would be 40.88°F, (45°F - 4.12°F). The 4.12°F comes from half of 8.25°F, and the 45°F is the saturated vapor (dew point) temperature in the evaporator. It is this average evaporator temperature that must be used for system design considerations.

System design, performance, and service conditions must be evaluated when incorporating or retrofitting with a zeotropic or near-azeotropic refrigerant blend. When HVACR service technicians are calculating subcooling values, they must use the bubble point values from the pressure/temperature chart, and when calculating superheat values, they must always use the dew point values from the chart. The average evaporator temperature occurs at the midpoint of the effective temperature glide. Always follow the manufacturer’s guidelines before retrofitting with any refrigerant, or system performance could be affected and injury may occur.

Report Abusive Comment