The HVACR industry is in the process of transitioning away from HFCs such as R-410A to alternative refrigerants that are mildly flammable (A2L). Because of their flammable nature, these refrigerants are referred to in terms that may not be familiar to contractors and technicians.

At the recently held HVAC Excellence National HVACR Education Conference in Las Vegas, Nevada, Jason Obrzut, director of industry standards and relations at ESCO Group, explained the properties of A2L refrigerants, as well as what the terminology means.

Levels of Flammability

First of all, it’s important to understand that refrigerants have different levels of flammability (and toxicity), which are governed by ASHRAE Standard 34, Designation and Safety Classification of Refrigerants. In the U.S., residential and light commercial air conditioning equipment has almost universally used refrigerants that do not propagate a flame (A1), such as R-22 or R-410A. But now new refrigerants, such as R-32 and R-454B will be coming on the market, and these are mildly flammable, or A2L.

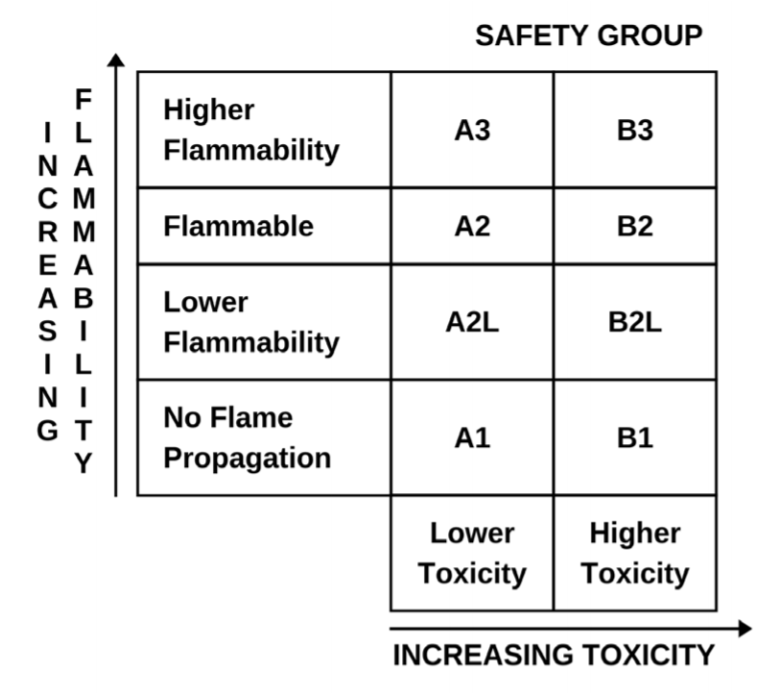

ASHRAE Standard 34 assigns an identifying reference letter and number to each refrigerant to classify it according to the hazard involved in its use, see Table 1. The capital letter designates a toxicity class based on allowable exposure, while the numeral denotes flammability. As Obrzut noted, “‘A’ designates low toxicity, while ‘B’ is higher toxicity. The numbers 1, 2, and 3 are the levels of flammability, and the lower the number, the lower the flammability.”

Click chart to enlarge

TABLE 1: ASHRAE Standard 34 assigns an identifying reference letter and number to each refrigerant to classify it according to the hazard involved in its use.

As far as flammability is concerned, ASHRAE has designated four classifications of refrigerants (there is no nonflammable classification for refrigerants, as most are capable of ignition when exposed to a high energy ignition source such as an open flame):

- Class 3 for highly flammable refrigerants such as hydrocarbons;

- Class 2 for flammable refrigerants such as R-152a;

- Class 2L for lower flammability refrigerants such as R-32 and R-454B; and

- Class 1 for refrigerants that do not propagate a flame when subjected to conditions specified by ASTM Standard E681.

A2L refrigerants were given that designation because of their lower flammability limit (LFL), which is an important term to understand. LFL is the minimum concentration of a flammable substance – in this case a refrigerant – that is capable of ignition when there is a sufficient mixture of air and the substance. It’s expressed as refrigerant percentage by volume, so the lower the number, the greater the probability for ignition.

“For example, R-290 has an LFL of 2.1%, which means when it reaches 2.1% of the air by volume, it can be considered a competent mixture, and it will burn (see Table 2),” said Obrzut. “A2Ls have a higher LFL, so you need a greater amount -- a larger leak -- and enough oxygen or air in order to achieve that competent mixture.”

| Refrigerant | R-32 | R-454B | R-1234yf | R-717 Ammonia | R-152a | R-290 Propane | R-600a Isobutane |

| Safety Group | A2L | A2L | A2L | B2L | A2 | A3 | A3 |

| LFL | 14.4% | 11.8% | 6.2% | 15% | 3.9% | 2.1% | 1.8% |

| Auto Ignition Temperature | 648°C 1,198.4⁰F |

496°C 924.8⁰F |

405°C 761⁰F |

651°C 1,203.8⁰F |

440°C 824⁰F |

455°C 851⁰F |

460°C 860⁰F |

| Minimum Ignition Energy (MIE) | 30 – 100 mJ | 100-300 mJ | 5,000 – 10,000 mJ | 100 – 300 mJ | 0.38 mJ | 0.25 mJ | 0.6 – 0.7 mJ |

| Burning Velocity | 6.7 cm/s | 5.2 cm/s | 1.5 cm/s | 7.2 cm/s | 23 cm/s | 46 cm/s | 41 cm/s |

| Heat of Combustion (HOC) | 3,869 Btu/lb | 4,420 Btu/lb | 4,408 Btu/lb | 9,673 Btu/lb | 2,708 Btu/lb | 19,905 Btu/lb | 19,000 –19,200 Btu/lb |

TABLE 2: LFL is expressed as refrigerant percentage by volume, so the lower the number, the greater the probability for ignition. (Courtesy of ESCO Institute)

R-32, for example, has an LFL of 14.4%, and R-454B has an LFL of 11.8%. On top of having a competent mixture of air and refrigerant, a high amount of energy is needed to ignite it, such as an open flame. “Essentially, we have to have a decent amount of refrigerant leak into a place where there’s enough air, and in that same place, we have to have some sort of open flame that keeps burning. The stars really have to align in order for ignition to take place,” said Obrzut.

Other Important Terms

Another important term to know is minimum ignition energy (MIE), which is the minimum electrical spark energy – in millijoules (mJ) – required to ignite a flammable gas/air mixture.

“As a reference point, consider the spark from a high-voltage spark plug, which produces 20-30 mJ of ignition energy,” said Obrzut. “Most A2L refrigerants are difficult to ignite, because they have an MIE way above that level. Even if we do have a competent mixture, where we have the right amount of fuel and the right amount of air, we're still going to need enough ignition energy to light that. In most instances, the high voltage spark isn't going to do it. Neither is a strip heater. Based on flammability testing, 15 kW strip heaters were not enough to ignite it. Neither were household appliances like toasters, hair dryers, and cordless drills.”

Heat of combustion (HOC) is another important term in understanding mildly flammable refrigerants. HOC is a measurement of the amount of heat released when a substance – in this case, a refrigerant – burns.

“When we burn a cubic foot of gas, it puts off a certain amount of heat, Btu per cubic foot,” said Obrzut. “The more heat it puts off, the greater the chance that it will spread to other fuel in the room, such as the walls, the curtains, the carpet, etc. Most of the A2L refrigerants have a lower heat of combustion, so if they do ignite and burn, they don't produce as much heat as other gases. For example, A2Ls have a much lower heat of combustion than A3 refrigerants, and the heat produced by combustion of most A2Ls is less likely to cause an ignition event to spread.”

Finally, there is burning velocity, which is the rate at which a flame front spreads relative to the unburned gas ahead of the flame.

“Essentially this is the speed at which the flame chases the gas,” said Obrzut. “For those of us who work with gas heat, when the furnace fills up with gas, and then the igniter comes on, there’s a pretty quick flame velocity. With A2L refrigerants, the burning velocity has to be less than 10 centimeters per second, making them less likely to sustain combustion after the initial ignition source has been removed. These refrigerants don’t burn straight across a room instantly. It's a very lazy, slow moving flame.”

By learning about the new terms -- LFL, MIE, HOC, and burning velocity -- it becomes easier to appreciate the differences between various classifications of refrigerants. And to ultimately understand that A2Ls are not nearly as flammable as A3s and pose little risk in cooling equipment.

Report Abusive Comment