The dispatcher called Bob about servicing an old oil furnace. This furnace is over 30 years old and the customer is adamant that he doesn’t want a new furnace, because the old one has lasted so long and is in such good shape.

Figure 1. This is a shaded pole motor that was used in some

furnaces. (Figures are from Refrigeration & Air Conditioning Technology,

5th Edition, by William Whitman, William Johnson, and John Tomczyk, published

by Delmar Cengage Learning.)

He and Bob went to the basement where the furnace is located. Sure enough, the furnace looked new, it was so clean. The customer said, “When this was installed 30 years ago, the company that installed it told me that it was made of commercial materials. I have kept it clean all of these years. Just wait until you take off one of the panels. It takes two hands to remove them. They are heavy-duty steel. They also installed this metal duct system that is as solid today as when it was put in.”

Bob looked around and said, “Boy, you are right about it being a nice looking system. This looks like a commercial system. I am going to get started and tune it up to perform up to your expectations. I will take efficiency readings before and after and show you the difference.”

The customer left and Bob went to work. The first thing that he did was run a combustion analysis on the furnace and it was operating at 68 percent efficiency. He thought that he could improve on this. The oil burner had been changed from a standard oil burner to a flame retention head burner, so the furnace itself had been upgraded.

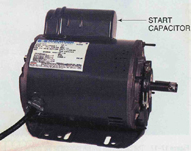

Figure 2. This is a capacitor start motor. These also come in

capacitor start and capacitor run for more efficiency.

Btu Buddy then appeared and asked Bob, “What seems to be the problem?”

Bob said, “I have never seen a belt drive fan on a residential unit. I know how to service it. I just don’t seem to know why they were ever used or why they started using direct drive motors.”

Btu Buddy started explaining, “Belt drive motors were used before we had multiple speed motors for furnaces. As you know, today all we see are multi-speed PSC (permanent split capacitor) motors. They are much lighter with fewer components to fail and are more efficient.”

“How can they be more efficient?” asked Bob.

Figure 3. This is a multi-speed PSC (permanent split capacitor)

motor. The fan would mount on the shaft and the motor has multiple-speeds.

“Then the engineers switched to 3,600 rpm motors. These motors are smaller and lighter for the same horsepower, so the fan could be made smaller also as it turns faster. This results in smaller furnace sizes. This reduced the size of large inventories and shipping costs. But they had one problem. Getting the motor from 0 rpm to 3,450 rpm, the usual running speed, in the same time that it took to get a 1,750 rpm motor up to speed created more noise during startup. Customers complained, but equipment kept being built.

“Then the multi-speed PSC motor came into favor and solved some problems.

• PSC motors have a soft startup. You must have noticed how slow they start.

Figure 4. This illustration shows the bearing locations for a

belt drive fan section. (Click on the image for an enlarged view.)

• There is no belt to have to adjust each year.

• The fan speed can be varied by just changing a wire on the motor terminal, rather than having to adjust a pulley and maybe go to a different belt size. Service trucks used to have racks of belts that the technician had to carry for use on service calls. Now, you carry a few common PSC motors that work for most service calls. Times change. The future is bringing in a new generation of motors for the future. These motors are called ECM (electrically commutated motors) that are used on the very high efficiency equipment. These motors are almost custom fitted to the furnace for a specific job. You are going to be back to where you can’t carry an inventory of motors in the future because they are all so different. They will also be very reliable.”

Bob then got busy and finished the oil burner tune up. The last thing that he did was a combustion analysis and the furnace was operating at 74 percent efficiency. He wrote the before and after test results on the service ticket and presented it to the homeowner.

The owner said, “Thanks for doing a good job on my antique furnace. I guess that I will get a few more years of good service out of this old furnace.”

Bob said, “I was really surprised at how good that furnace performed. It is old, but really solid. Some of the older equipment is really built to give good service and last a long time. You could change to a more efficient furnace, but it would take many years to make up the difference.”

Btu Buddy then said to Bob, “You did a good job of working with that gentleman that was set in his ways. As it turns out, he was very right about his antique furnace.”

Publication date:04/21/2008

Report Abusive Comment