The PotableAire system has been undergoing continuous development for the last three years. The unit was first introduced as the LiquidAire system, but underwent a name change when improvements were made and the technology advanced.

"We enhanced the system to produce substantial amounts of water, even in arid parts of the world where grey water may be available," said Larry Klekar, national accounts sales manager for Munters. "Increased water production, efficiency of the water-making system, and the ability to mobilize the unit were some improvements made."

The product matured from a humble beginning.

"We were always aware of the condensate being made, but the volume of condensate our units were making was surprising - so we decided to utilize it," said Klekar. "The unit was first utilized on a Munters facility for employees. The water is used for the drinking water and coffee and ice machines at Munters."

How It Works

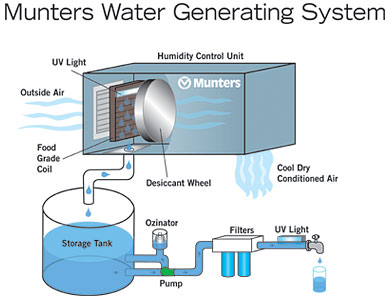

In a PotableAire system, outside air passes through an efficient air filter, which purifies it by removing dust, pollen, mold spores, and other airborne particles. The moisture is condensed from the outside air and collected in an ultraviolet-protected chamber. The condensate water is stored in a holding tank, which is continuously ozonated to prohibit bacterial growth. As needed, water is drawn from the tank, filtered through a VOC carbon filter, and passed through an ultraviolet sanitation light. After this process, the water is now purified for drinking, and the cooled, dry air is sent indoors to create a comfortable indoor environment."Every air conditioning system generates condensate from its cooling coils, which is just dumped down the drain," said Klekar. "This system captures this virtually distilled water and turns it into drinking water."

The resulting water has been tested for 28 metals, plus 10 wet chemistries, including coliform bacteria. All of the elements registered at well below industry standards, according to the San Antonio Testing Laboratory.

Texas requires water to have fewer than 500 parts per million (ppm) of total dissolved solids (TDS) for it to be rated potable. The testing lab found that the water from the PotableAire system had zero ppm TDS, compared to the city of San Antonio's water rating of 220-240 ppm TDS.

"In our 16 years of water analysis, Munter's water is without a doubt the purest water we have ever tested," said Richard Hawk, owner and general manager of San Antonio Testing Laboratory.

Overseas Customers

At this point, the PotableAire is doing better internationally in places where water is not so readily available. According to a 2003 United Nations report, a worldwide water crisis will create water shortages affecting more than half of the world's population within 50 years. About 90 percent of the severe problems are in developing nations."The greatest impact will be in third world countries where pure drinking water is not available," Klekar said. "Asia is a good example where little or no pure drinking water exists, but the humidity is very high. It is an ideal environment for the product, and the people could reap the benefits."

Depending on the size of the unit, the system can produce as much as 13,134 liters of water per day. Munters recently shipped a unit to Thailand where the government is using it as a demo unit.

Another is in Jakarta, Indonesia, where PT.Eternair Water Indonesia is using the system to air condition a manufacturing plant while capturing water, which will be bottled for sale.

"I am very pleased to be the first in the world to open a water bottling plant that will use air as the source for drinking water," said Budhi Haryanto of PT.Eternair Water Indonesia.

"Our plant in Jakarta will use the new PotableAire system to produce water, while also air conditioning the plant. We expect our customers to be excited about drinking the purest form of drinking water on the planet Earth."

PT.Enternair expects water sales to pay for the unit within two years. At the moment, the unit is producing 3,500 gallons per day. There are plans in the future to add four more systems.

"Humidity control is necessary in tropical areas, where the quality of drinking water tends to be poor," said Klekar. "We're bringing the two technologies together to solve both problems."

Closer To Home

The PotableAire is also being looked at closer to home. There are preliminary plans for a water bottling operation to be started in South Texas within the next 12 months. In addition, others are considering the application for "Green Building" applications or to qualify for Leadership in Energy and Environmental Design (LEED) credits."The military is interested in using the system for remote areas where water is inaccessible and air conditioning is needed. Utilizing air for air conditioning the soft buildings while capturing the water for personnel is a primary focus. Disaster recovery is also an important focus because of contaminated water or lack of pure water," Klekar said.

Publication date: 08/15/2005

Report Abusive Comment