As an electric motor’s rotor turns in close proximity to the motor windings, a bucking voltage or back electromotive force (EMF) is generated. The back EMF (BEMF) generated across the start winding is greater than what is generated across the run winding. This phenomenon happens because the start winding usually has longer wire, smaller diameter wire, or more turns of wire, thus has a greater inductive reactance than the run winding. Because of this, potential relays are sometimes referred to as voltage relays since they rely on the BEMF or voltage that is generated by the motor for their operation.

Function and Operation

If the potential relay is malfunctioning, the compressor motor is in danger of not starting, stalling, locking rotor, or even burning out. Many motor windings have been opened or weakened by malfunctioning potential relays. Because of this, it is of utmost importance for service technicians to understand not only how this starting relay operates, but also how to troubleshoot the components that make up the potential relay.

The function of a potential relay is simply to assist in starting the electric motor. Potential relays are commonly found on many smaller single-phase capacitor-start, capacitor-run motors in the HVACR industry.

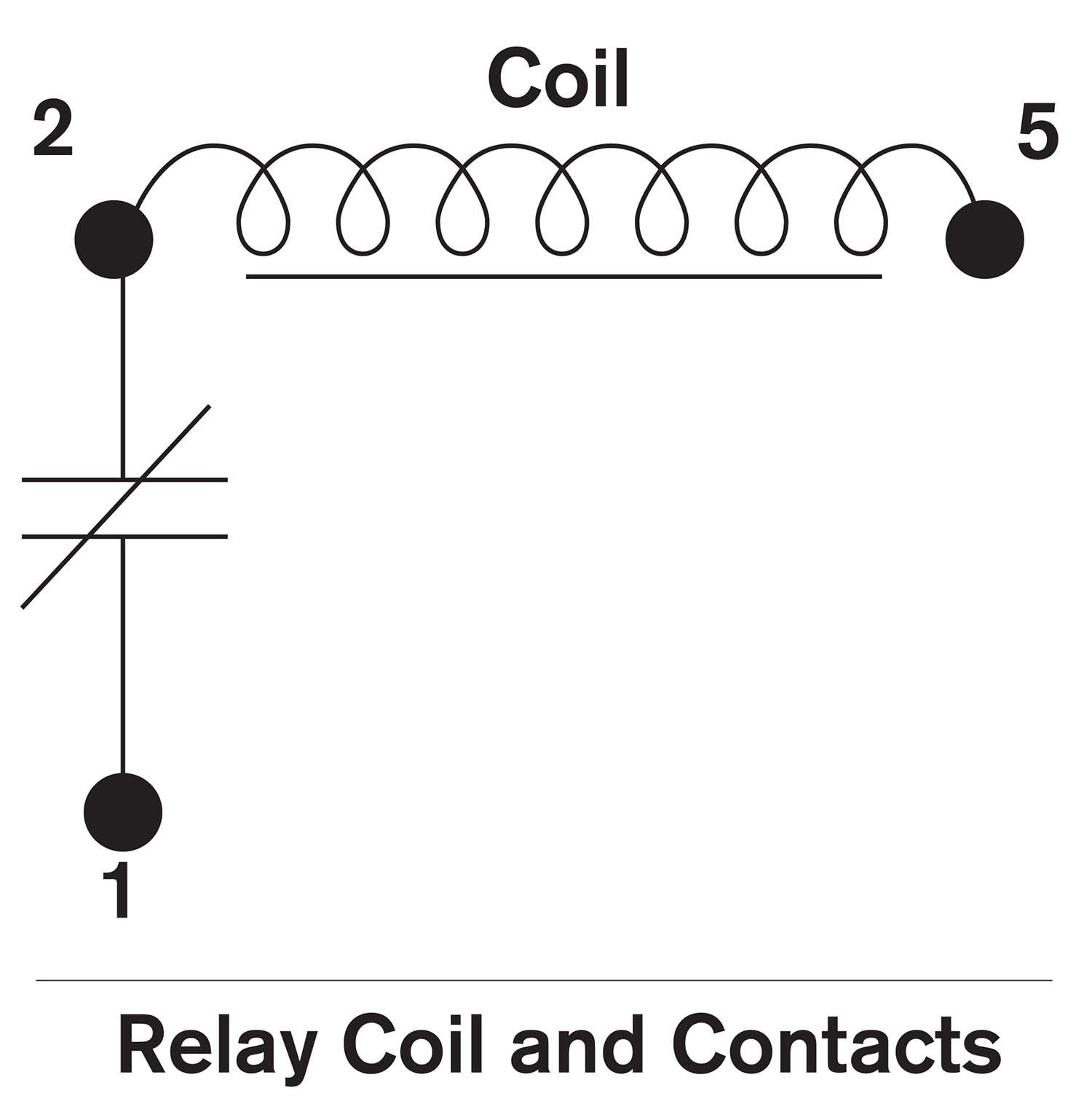

The potential relay consists of a very high resistance coil and a set of normally closed contacts, both of which are encased in a small plastic housing. A run and start capacitor can also accompany the potential relay (see Figure 1, top of page). These three components are often referred to as a hard start kit. The relay coil is wired between contacts 2 and 5, while the normally closed contacts are wired between contacts 1 and 2 (see Figure 2). Other terminal designations on the relay are usually for connecting wires and acting as wire nuts. They are often used for incoming power, fans, or capacitor wire connections and are referred to as inactive or convenience terminals.

Click figure to enlarge

FIGURE 2: The relay coil is wired between contacts 2 and 5, while the normally closed contacts are wired between contacts 1 and 2. (Courtesy of John Tomcyzk)

Once power is delivered to the single-phase motor, both the run and start windings will be in the circuit in series with the start winding. This happens because the contacts between terminals 1 and 2 of the potential relay are normally closed. The motor’s rotor will now start to rotate or turn. In Figure 3, notice that the run and start capacitors are wired in parallel to one another, yet both are in series with the start winding. The capacitance of capacitors wired in parallel will give the motor more starting torque because the capacitors are in series with the start winding.

Click figure to enlarge

FIGURE 3: The run and start capacitors are wired in parallel to one another, yet both are in series with the start winding. (Courtesy of John Tomcyzk)

As the motor’s rotor turns faster and faster, trying to reach its synchronous speed, a generating voltage effect is created from the rotor being a large metal mass rotating very close to the motor’s windings. Because the start winding is wound with a longer and thinner wire, more voltage or BEMF will be generated across it than across the run winding.

BEMF can be measured with a voltmeter across the start winding while the motor is running. BEMF is often higher than line voltage and can reach as high as 500 volts or more, depending on the design and speed of the motor. The BEMF’s polarity opposes the line voltage’s polarity so its magnitudes will not be added. All motors generate different BEMF values, so potential relays must be sized and chosen individually for each compressor.

Because the potential relay’s coil is wired in parallel to the start winding, this same voltage (BEMF) will occur across the relay coil. An electric circuit with voltage and current will be generated in the start winding and relay coil, causing the relay coil to energize and open the contacts between contacts 1 and 2. This action occurs, because the relay coil is wrapped around an iron core that will magnetize once the coil is energized. This opening of contacts causes the start capacitor to be taken out of the circuit. The motor will continue to run as a permanent split capacitance (PSC) motor with only a run capacitor in series with the start winding. Once the operating control opens and power is taken away from the motor, the motor speed will gradually decrease along with the BEMF generated. The relay coil will de-energize and the contacts between terminals 1 and 2 will return to their normally closed position as the motor comes to a stop.

Troubleshooting

A simple ohmmeter is all that is needed to troubleshoot a potential relay. After taking all connecting wires off the relay, measure the resistance across the 1 and 2 terminals. The resistance should read close to zero, since they are normally closed contacts. If the reader reads infinity, the contacts are stuck open, and the relay should be discarded and replaced. Open contacts will prevent the start capacitor from being in the circuit. This can lock the rotor and cause locked rotor amps (LRA) under certain conditions, thus opening the compressor’s protection device. Short-cycling on the compressor’s protection devices can overheat and open a winding in time.

The relay contacts may also be stuck or arced in the closed position. In this case, the start capacitor would never be taken out of the circuit, and a rumbling sound with high amp draws would open motor protective devices. If the contacts are stuck in the closed position, the relay will have to be checked in the running mode, since the contacts between 1 and 2 are normally closed when not in operation. Once the motor is up and running, use a voltmeter to measure the voltage across terminals 1 and 2. A voltage reading of zero volts would prove that the contacts are not opening. Also, high amp draws in the start winding circuit is a telltale sign that the contacts have not opened.

For coil troubleshooting, after disconnecting all wires from the relay, ohm the coil between terminals 2 and 5 on the relay. Since this coil should have very high resistance, make sure to use the proper scale on the ohmmeter if it is not self-scaling. The R X 100 scale is a good one to use, as the R X 1 scale can fool a technician into believing that there is an open coil because of the coil’s extremely high resistance. It is not uncommon to have the resistance read in the many thousand ohms. If the ohmmeter reads infinity on the R X 100 scale, the relay coil has opened, the relay should be discarded, and a new one installed. An open relay coil will prevent the contacts between 1 and 2 from opening because of no magnetism in the relay coil’s iron core. This, again, will cause high amp draws and a rumbling sound from the capacitor staying in the circuit too long.

The pick-up voltage for a specific potential relay will be listed as a minimum and a maximum. The actual pick-up voltage must stay within its range for proper operation. The pick-up voltage is the BEMF voltage generated across the start winding by the motor’s rotor when it is up to about ¾ synchronous speed. If the pick-up voltage generated by BEMF is under the minimum, the contacts between terminals 1 and 2 will never open. The start capacitor will then stay in the circuit, which will cause high amp draws and can open motor protective devices. However, if the pick-up voltage generated by BEMF is above the maximum, the relay coil stands a good chance to overheat and open circuit. Again, the contacts between 1 and 2 would stay closed, causing high amp draws if the relay coil opens circuit.

Potential relays have a drop-out voltage rating, which is the BEMF voltage that must be generated across the relay coil to “hold” the contacts open once they have been picked up (opened). Often, it takes more BEMF (pick-up voltage) to pick up and open the contacts than it does to hold them open. Once the cycling control opens the circuit, the rotor will decrease in speed, thus generating less BEMF across the start winding and relay coil. As the BEMF drops below the dropout voltage, the contacts between 1 and 2 will return to their normally closed position and be ready for the next starting cycle.

Because of these three voltage rating specifications, potential relays must be sized to each individual compressor. Consult with a service manual, the compressor manufacturer, or a supply house for information on selecting the correct potential relay. Replacement relays can be cross-referenced for different manufacturers using convenient tables via the internet. Whenever possible, the model number on the new relay should be used when ordering a new relay. There are potential relays on the market with an adjustable pick-up voltage range.

Potential relays also have a continuous voltage rating. This is the maximum BEMF that the relay’s coil can tolerate continuously without overheating and opening circuit.

Older, weak, or internally damaged compressors often cannot keep a synchronous speed because of a damaged winding, weak run capacitor, too much load, out of tolerance from age, or many other reasons. It is for these reasons that they may have a hard time maintaining their synchronous speeds once up and running. Once their speed decreases, less BEMF is generated, and it may be below their drop-out voltage. The relay contacts will then close and the start capacitor will be back in the circuit in series with the start winding. This scenario will often cause a motor winding to burn or open, the overload to open, start capacitor to become defective from overheating, or the relay contacts to open and close too frequently, causing them to arc shut. Often a capacitor and/or potential relay will be replaced and the system will run fine for a couple weeks or months and then the same scenario will occur again. In these cases, it is often advantageous to replace the aged compressor, potential relay, and both capacitors.

Report Abusive Comment