When a TXV underfeeds refrigerant, the entire refrigeration system suffers. The evaporator will be starved of refrigerant, which in turn will starve the compressor of refrigerant. The condenser will also be starved of refrigerant, because the compressor feeds the condenser superheated refrigerant vapor. Most of the refrigerant will be in the receiver and liquid line, and the mass flow of refrigerant throughout the system will be greatly reduced. The low mass flow rate will also result in stagnated liquid refrigerant in the bottom of the condenser, which can give the system slightly higher condenser subcooling measurements.

When a TXV underfeeds refrigerant, it may be due to a restriction, which can be caused by the following:

- TXV being adjusted too far closed;

- Foreign material in the TXV orifice;

- Manufacturer's defect in the valve;

- Oil-logged TXV from liquid refrigerant flooding the compressor’s crankcase;

- Too much oil in the system;

- Plugged inlet screen on TXV;

- Wax buildup in TXV valve from wrong oil in system;

- Sludge from the byproducts of a compressor burnout; or

- Partial TXV orifice freeze-up from excessive moisture in the system.

Major Symptoms

Some of the major symptoms of a TXV underfeeding refrigerant include:

- Low amp draw from starved compressor;

- High compressor superheat;

- High compressor discharge temperature;

- Low condensing (head) pressure;

- Low condenser split;

- Slightly higher condenser subcooling;

- Low evaporator (suction) pressure;

- High evaporator superheat; and

- Short-cycle on low-pressure control (LPC).

High compressor superheats and low suction pressures will cause low-density suction vapors to enter the compressor, and the compressor will also be partly starved from the TXV being restricted. These factors will put a very light load on the compressor, with low mass flow rates of refrigerant causing the amp draw to be low.

High compressor superheats and discharge temperatures are caused from the evaporator and compressor being starved of refrigerant. The compressor will see a lot of sensible heat coming from the evaporator and suction line, along with its heat of compression and motor heat. If it’s refrigerant-cooled, the compressor will probably overheat from the lack of refrigerant cooling.

Compressor discharge temperatures reflect all of the latent heat absorbed in the evaporator, the evaporator superheat, all of the suction line superheat, and all of the heat of compression and motor generated heat at the compressor. It is at the discharge temperature where all of this heat is accumulated and now must start to be rejected in the discharge line and condenser. It is of utmost importance for service technicians to measure this temperature when servicing and troubleshooting a refrigeration or air conditioning system. Take the temperature of the suction line entering the compressor and the suction pressure at that point, and convert it to a saturation temperature. The difference between the two is the compressor superheat.

Compressor superheat is often referred to as total superheat, because it consists of suction line and evaporator superheat. Refrigerant-cooled compressors rely on their return gas to be cool enough to cool their motor windings and cylinder walls. Compressors should have enough compressor superheat to ensure that when the TXV hunts, there will not be liquid coming back to the compressor. However, some compressor manufacturers require that the compressor return gas temperature should not be hotter than 65°F or the gas will not be dense enough for motor winding and cylinder cooling. Always consult with the compressor manufacture for maximum return gas temperatures.

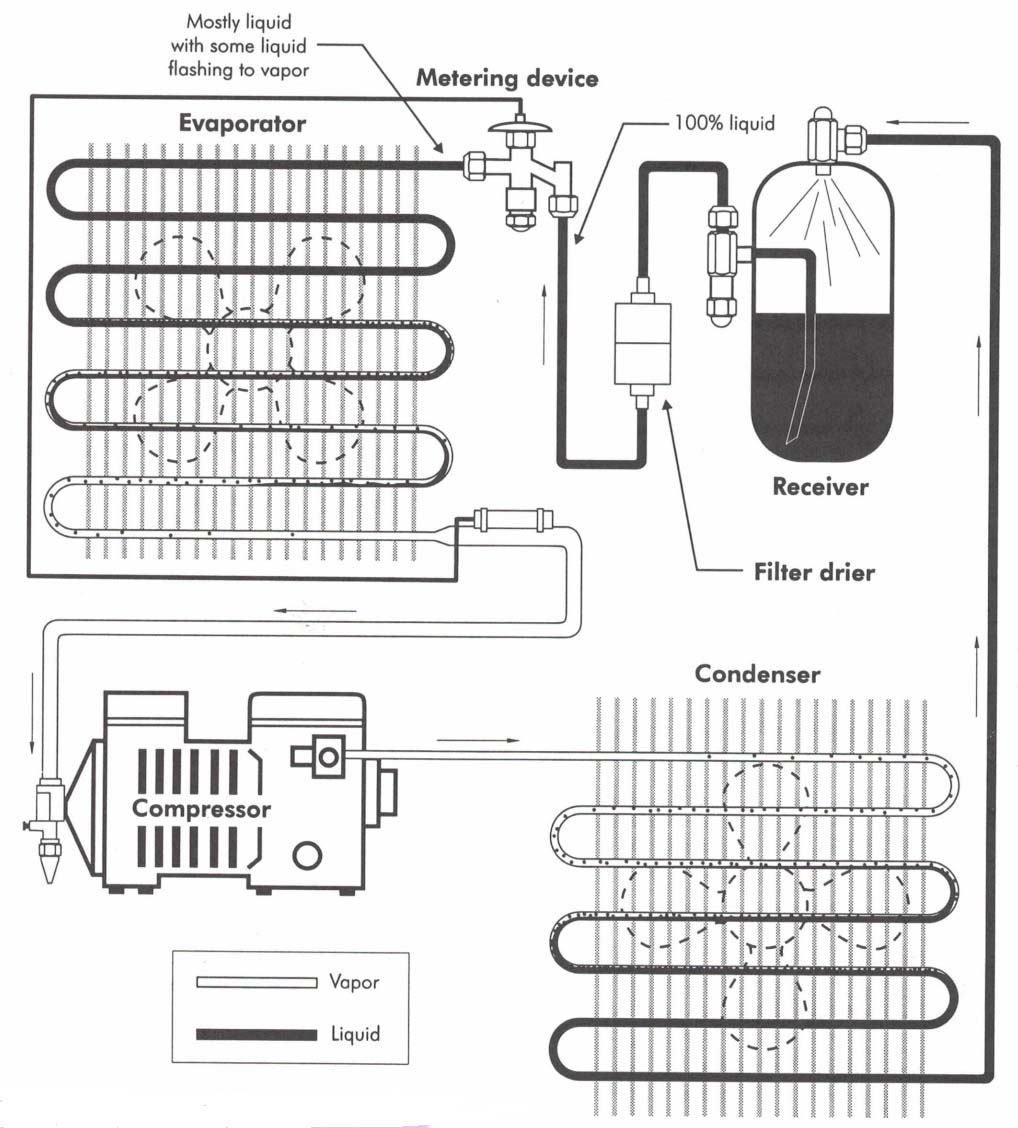

When the evaporator and compressor are starved of refrigerant, the condenser will be, too, because of these components being in series with one another (see Figure 1). There will be little heat to eject to the ambient surrounding the condenser, allowing the condenser to operate at a lower temperature and pressure. This is because it does not need a large temperature difference between the ambient and the condensing temperature to reject the small amount of heat it receives from the evaporator, suction line, and compressor.

Click diagram to enlarge

FIGURE 1: When the evaporator and compressor are starved of refrigerant, the condenser will be, too, because these components are in series with one another. (Courtesy of John Tomczyk)

This temperature difference is referred to as the condenser split. If there were large amounts of heat to reject in the condenser, the condenser would accumulate heat until the condenser split was high enough to reject this large amount of heat. High heat loads on the condenser mean large condenser splits, while low heat loads on the condenser mean low condenser splits.

In this case, there is a low heat load on the condenser because of the evaporator being starved of refrigerant and not absorbing any heat load to give to the condenser. Most of the refrigerant will be in the receiver, with some in the condenser. The condenser subcooling will be a bit high because of this, and the refrigerant flow rate will be low through the system from the restriction. This will cause what refrigerant that is in the condenser to remain there longer and gain more subcooling. Note that an undercharge of refrigerant will cause low subcooling.

When the TXV is restricted and the evaporator is starved of refrigerant, the evaporator will become inactive and run high superheat. As mentioned earlier, this will cause the compressor superheat to be high. The 100% saturated vapor point in the evaporator will climb up the evaporator coil, causing high evaporator superheats. The compressor will also be starved of refrigerant and will pull itself into a low-pressure situation. It is the amount and rate of refrigerant vaporizing in the evaporator that keeps up the suction pressure. A small amount of refrigerant vaporizing in this scenario will cause a lower suction pressure.

The compressor may short cycle on the LPC depending on the severity of the restriction in the TXV. The low suction pressures may cycle the compressor off prematurely. After a short period of off time, the evaporator pressure will slowly rise from the small amounts of refrigerant in it, and this will cycle the compressor back on. This short cycling may keep occurring until the compressor overheats. Short cycling is hard on controls, capacitors, and motor windings.

Similar Symptoms

The symptoms of an underfeeding TXV system are very similar to a system with a refrigerant undercharge; however, the undercharged system will have low condenser subcooling levels.

Service technicians often confuse an undercharged system with a restricted metering device. Adding refrigerant to a system with a restricted metering device will only raise the condenser subcooling amounts to a level where the head pressure will keep elevating. This is caused from a lack of internal volume in the condenser to hold the added refrigerant. Even the receiver may overfill if too much refrigerant is added. The receiver is designed to have a 25% refrigerant vapor head for safety reasons. If a receiver system is ever overcharged excessively, the receiver may become full of 100%, or near 100% liquid refrigerant, and thus become a dangerous pressure vessel with excessively high head pressures. If the system is then pumped down for any reason, even more dangerous head pressures will be experienced.

A system with a restricted metering device also has the very same symptoms as a system with a liquid line restriction. This is because the TXV is actually part of the liquid line, which begins at the outlet of the receiver and includes the filter drier, sight glass, and any other components located between the receiver and TXV.

The filter drier is a very likely component to become restricted from moisture and/or debris accumulation and will give the same symptoms as a restricted TXV. However, if the filter drier is restricted enough, it will sometimes feel cool or cold to the technician’s touch. This phenomenon happens from some of the liquid refrigerant experiencing a slight pressure drop and expanding into vapor as it travels through the filter drier. Vapor bubbles in the sight glass downstream of the filter drier can also be observed if this phenomenon happens. This is why it is of utmost importance to have the liquid sight glass downstream, not upstream, of the filter drier.

These liquid line restrictions all cause the evaporator, compressor, and condenser to be starved of refrigerant. This will cause symptoms of low suction pressures, high evaporator and compressor superheats, low compressor amp draws, and low head pressures.

Report Abusive Comment