The Gold award in the Components and Accessories category goes to Zoomlock’s Push fittings, which are push-to-connect refrigerant fittings. The robust brass fittings are used to connect copper tubing in refrigeration and air-conditioning systems, and they produce secure, leak-free connections without the use of open flames or special pressing tools.

“ZoomLock Push fittings are easy and fast to install,” said Joseph Freese, product manager, Parker Hannifin. “Connecting copper pipes without a flame provides a safer installation process that saves time and eliminates the need for hot work permits on the job site.”

The fittings have a maximum rated pressure of 870 PSI and are approved for the most common refrigerants in the market today. The R410A Optimized series is a push-to-connect refrigerant fitting with a 10-year warranty. The fittings can be used for any air conditioning and refrigeration installations, including residential air conditioning, commercial air conditioning, variable refrigerant flow (VRF) systems, display cases, and reach-in merchandisers.

For technicians, the ease of installation makes ZoomLock Push fittings ideal for residential split and mini split air conditioning installations. Technicians do not have to haul heavy tools or bottle gases. Installation time is significantly reduced, allowing the technician to complete their job faster and more reliably. The ZoomLock Push R410A Optimized fittings contain a triple O-ring design and carry a 10-year warranty to ensure the technician’s confidence in the new technology.

“ZoomLock Push comes in a compact form with a variety of sizes and connection styles that will allow the technician to complete almost any job in almost any location,” said Freese. “ZoomLock Push comes individually packaged in sealed bags to ensure that the fittings stay debris-free and ready to use.”

By eliminating concerns with oxygen-acetylene torches and flames, ZoomLock Push gives technicians more flexibility in where and when they can work. It also offers a clean installation process with no need to nitrogen-purge the lines.

“The product is great to work with,” said Greg Wolf, service department manager at Snell Services. “We have had zero problems with Push fittings.” He added that the product is convenient, saves time, and is clean.

When designing the product, Parker Hannifin conducted customer surveys and interviews for market research. Going forward, the company plans to further educate the market on the benefits of the ZoomLock Push push-to-connect refrigerant fittings. There are also plans to expand the product offerings as a flame-free solution for installing refrigerant lines.

“Parker will continue to ensure the product offering is compatible with future refrigerants and industry needs,” said Freese. “ZoomLock Push builds on the success of ZoomLock press-to-connect fittings and is a great labor and time-saving solution that impacts the contractor’s bottom line.”

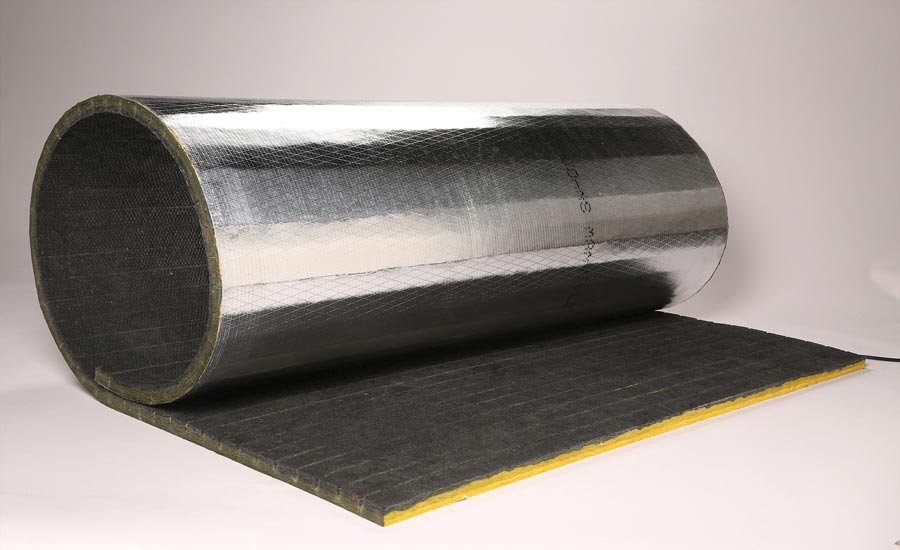

The Silver award in the Components and Accessories category goes to Johns Manville’s Spiracoustic Plus® VVSD.

The Spiracoustic Plus Spiral Duct Liner, VVSD (very, very small diameter) is 1 inch thick, and is a pre-kerfed, single-wall spiral duct insulation engineered specifically for spiral ducts with an outer diameter of 6 to 8 inches. The duct liner is designed to eliminate the need for costly double-wall configuration in round air ducts.

The product features Permacote acrylic coating for added airstream surface protection, is laminated with a reinforced FSK (foil scrim kraft) facing, and is engineered for ideal thermal and acoustical control. The tough, acrylic polymer Permacote coating helps guard against the incursion of dust or dirt into the substrate, minimizing the potential for biological growth.

“Since this product is ready-made for installation, contractors do not have to have extensive experience in kerfing and refabricating the material for a successful installation,” said Brennan Hall, senior HVAC product manager, Johns Manville. “This helps bridge the knowledge gap as the industry faces retiring skilled professionals and a lack of skilled labor.”

The Bronze award in the Components and Accessories category was won by Nibco Inc.’s Nibco PressACR.

The PressACR is a copper press-to-connect fitting product line designed for HVACR applications, and it features a gray HNBR seal that has been specially formulated for those applications. The press-to-connect technology provides fast and reliable installations, and eliminates the need for flame or fire watch, providing a safer installation environment.

“The unique patent pending fitting design and crimp pattern for use in high-pressure systems provides for consistent joint quality, which means fewer callbacks and reliable performance,” said Sally Boyer, manager, marketing communications, Nibco Inc. “Contractors can improve installation time, quality, and overall safety.”

Report Abusive Comment