Chillers are a key component of commercial HVAC systems. Of course, like all parts of the commercial HVAC business, this past year proved challenging. Overall, demand softened, but some segments saw considerable strength. Meanwhile, trends in technology and refrigerants are moving the segment forward.

Gaurang Pandya, president of Carrier Commercial HVAC, said that all commercial segments were down in the mid to high single-digit range last year. However, air-cooled chillers had the smallest dip and seem to also be recovering the quickest.

“With better news on the horizon, we believe the demand for all types of new chiller equipment will grow throughout 2021,” Pandya said.

One area of growth that should continue is health care. Todd Grabowski, vice president of chillers and air handlers for Johnson Controls, said that the health care industry has seen an increased need for improved indoor air quality, expanded HVAC, and building controls capability and facility resiliency during the pandemic. Grabowski said a growing demand for health services during the pandemic means that health care facilities require consistent cooling capabilities at all hours of the day while ensuring efficient, safe, and sustainable performance.

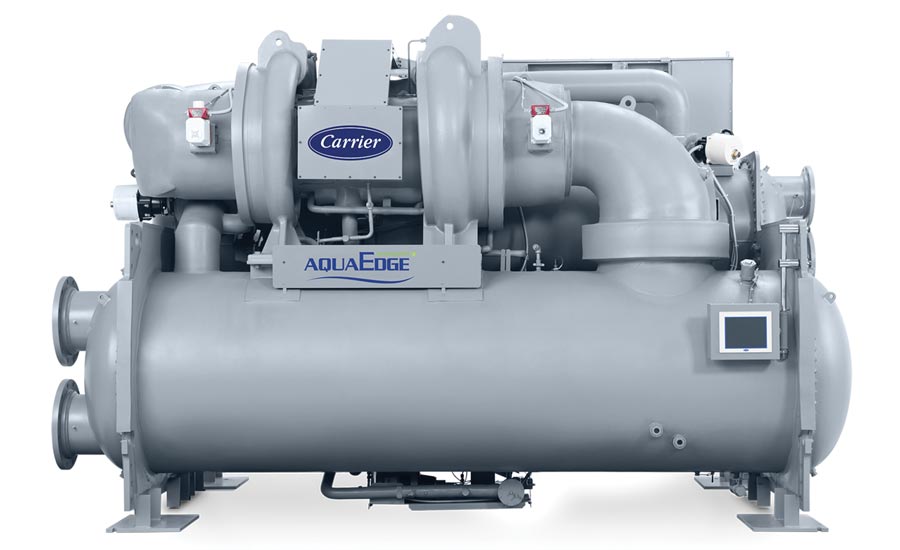

TOP CONCERNS: Carrier’s AquaEdge 19DV was designed to minimize environmental impact while also providing energy efficiency. Its two-stage back-to-back compression allows for effective heat recovery. (Courtesy of Carrier)

This extends to pharmaceutical research labs that work on vaccines and other treatments to stem the effects of COVID-19. These facilities require precise temperatures, clean indoor air, and reliable performance around the clock to meet the needs of the facility, Grabowski said.

The same holds true for data centers, which saw a surge in demand as everything from school to shopping went online. If the servers at a data center are too hot or cool, it could lead to a full system shutdown, causing costly downtime or equipment failure, Grabowski said.

“Air-cooled, variable-speed drive chiller technology can reduce the risk of cooling disruption in mission critical facilities because there is no inrush of current as it restarts,” he said. “This means that the chiller’s compressor can be restarted together to allow full capacity performance much quicker compared to standard chillers.”

Variable-Speed Motors Gain Steam

Victor Marinich, global segment marketing director of air conditioning for Danfoss, agrees that the use of variable speed motors is the biggest technological development in terms of chillers. These motors are used on pumps, fans, and in the compressor.

“The technology continues to develop, offering larger operating envelopes and better energy savings than in years past,” Marinich said.

The transition to variable-speed motors opens the door for more electronics in chillers, he said. These enable communication both within the chiller itself as well as with other equipment in the cooling loop. Grabowski said advanced control schemes, system optimization, artificial intelligence, model predictive control, and equipment learning are all being explored as solutions to optimize the real-time complexities of operating systems.

Oil-free compressors also continue to become more mainstream, Marinich said. They were once limited to water-cooled applications. Today, they are used in air-cooled systems, high ambient units, and other applications.

Many manufacturers are incorporating magnetic bearing technology in new chiller designs, Grabowski said. These improve chiller operational efficiency and lower maintenance requirements. In other chiller technologies, he said, combined heating and cooling systems leveraging absorption chillers, heat pump chillers, and heat recovery chillers see growing opportunities.

Pandya said Carrier is now offering several “free cooling” solutions — a strategy for leveraging natural air temperatures. One of these is a water-side economizer that, when added to an air-cooled chiller, allows the owner to take advantage of lower outdoor air temperatures to cool their building or process. This can result in thousands of dollars in energy savings per year while reducing maintenance costs and mechanical room space.

Overcoming Supply Issues, Looking Forward

The pandemic affected demand, and it also affected supply. Pandya said this was especially true early on. He said Carrier, like all other companies, had to learn to cope with the global situation and work with its suppliers.

“Enhancements were made not only to our facilities but also to those of our suppliers to help ensure a safe working environment for all employees,” Pandya said.

Carrier executives believe most these issues have been resolved, he said, and the process of solving these issues will make chiller production — and all other production — more reliable going forward.

Looking beyond the pandemic, the biggest trend impacting the chiller market is sustainability. Grabowski said system efficiency is factored into building and equipment design through regulatory decisions and green programs that aim to help building owners measure and reduce energy consumption. But the biggest area for sustainability when it comes to chillers is refrigerants.

Regulators and legislators are dictating that the industry move to refrigerants with lower global warming potential (GWP).

“Each refrigerant transition presents challenges for building owners and engineers,” Grabowski said. “With the industry shifting to low-GWP refrigerants, we caution [against] immediate transitions and recommend evaluating the economic, safety, and performance implications of new refrigerant alternatives with current and future chiller technology. Applications need to be considered as well when discussing refrigerant choice, since different climates require specific refrigerants to deliver optimal performance.”

He said any new refrigerant that is produced must avoid making large investments in chiller technology obsolete before their time. Marinich points out that a wide range of refrigerants was being offered to the market several years ago. System simulations, unit designs, and lab testing reduced that list to a handful of viable solutions for each application.

“Through close cooperation and partnership and by following legislative and market dynamics, we’re working to develop next-generation products that will exceed industry requirements,” he said. “We ensure our solutions are safe, efficient, and will help the manufacturer reach their design goals.”

Report Abusive Comment