If you have a stock of refrigerant and are not yet familiar with the letters “GHS,” be aware that you soon will be, because your Occupational Safety and Health Administration (OSHA) inspector certainly understands its meaning.

The revised OSHA Hazard Communication Standard (HCS) now incorporates portions of the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which, according to OSHA, will benefit workers at more than 5 million workplaces in the U.S. by reducing confusion about chemical hazards, facilitating safety training, and improving knowledge of the hazards, especially for low-literacy workers.

“Compliance with OSHA’s standard will result in chemicals being classified according to their health and physical hazards with consistent labels and safety data sheets for all chemicals made in the U.S. and imported from abroad,” said Kimberly Darby, spokesperson for OSHA communications.

OSHA estimates the revisions will prevent more than 500 workplace injuries and illnesses and 43 fatalities annually.

THE BACKGROUND

The HCS was first issued in 1983 and revised in 1987-1989 and 1994.

“While those changes helped to improve employee safety and health, it became clear that a more standardized approach to classifying the hazards, and conveying that information, would provide further improvements in American workplaces,” Darby said. “The latest revisions provide a standardized approach, which will enhance both employer and worker comprehension of the hazards and help to ensure appropriate handling and safe use of workplace chemicals.”

According to Darby, there are different requirements if an employer has “refrigerant containers in stock.”

• As a chemical manufacturer, if you are shipping chemicals to a downstream user after June 1, 2015, you must provide a new HCS label and safety data sheet (SDS) with the next shipment you send to your clients or downstream users.

• If you are a chemical distributor and are shipping chemicals that are not being altered or repackaged from another manufacturer, you have until Dec. 1, 2015, to relabel and provide SDSs to any clients or downstream users.

• If you have the chemicals in stock at your facility and your own employees are using them in the normal course of their job duties, this use would qualify under workplace label guidelines. Under such guidelines, employers must ensure each container of hazardous chemicals in the workplace is labeled, tagged, or marked with the same six label elements or a “product identifier and words, pictures, symbols, or combination thereof, which provides general information regarding the hazards of the chemicals, and, in conjunction with the other information immediately available to employees under the hazard communication program, will provide employees with the specific information regarding the physical and health hazards of the hazardous chemical.”

Sally Smart, technical safety specialist, Grainger, helped explain this last point, which would apply to many contractors.

“Basically, OSHA has come out with a new ‘shipped container label’ that must include six pieces of information,” Smart said. “However, OSHA is continuing to grant employers who are purchasing these chemicals the flexibility to use whatever workplace label they want within their workplaces, as long as it communicates the same hazards that are on the shipped container label.”

This means contractors or wholesalers who keep a supply of refrigerant on hand must look at the shipping label on product that’s coming in and decide what type of label they’d like to use for internal purposes.

“Whoever is looking at the product that’s coming in to the receiving dock is going to have to be trained to understand the shipped container label and recognize what it’s telling them,” Smart said.

MAKE IT A DATE

What is the implementation timeframe for GHS? That’s a simple question with a not-so-simple answer. The short answer is that OSHA is allowing some companies that have old stock with HCS 1994 labels to go through their stock as they use it.

The longer answer, according to Smart, is that, as of June 1, 2015, raw material chemical manufacturers and importers were to classify their products and incorporate all of the required information on the shipped container label on all of their products, and also incorporate the 16-section SDS with all shipments. Distributors were given an extra six months, until Dec. 1, to clear out inventory. The end date for all is June 1, 2016. As of that date, all employers must look at what they’re using as a hazardous communication program and update it — if necessary — to meet the revised HCS.

In late 2014, a group of chemical formulators; however, asked OSHA to extend the June 1, 2015, deadline for classification and communication of the hazards associated with formulations/mixtures. OSHA did informally provide guidance to its inspectors not to cite chemical formulators/mixture manufacturers who — through no fault of their own — were not receiving enough information from their raw material chemical suppliers to meet the June 1, 2015, deadline, Smart said. OSHA’s “internal guidance,” in effect, gives mixture manufacturers six additional months to classify their mixtures and provide updated SDSs based on the classification, and then an additional six months from that date to provide an updated shipped container label. If needed, distributors of chemical formulations/mixtures have until Dec. 1, 2017, to clear out inventory of 1994 labeled product, although the manufacturers are required to provide updated information to distributors as soon as it’s available, and distributors are required to immediately pass it along to their customers.

Does any of this mean contractors or distributors would need to relabel their entire stock of refrigerant mixtures? It’s unlikely. OSHA has said it doesn’t foresee any relabeling because extending the deadline out to Dec. 1, 2017, is going to take care of all old stock.

“Do people have to relabel? No, they do not,” Smart said. “They need to make sure they’re working with their suppliers to ensure they’re getting the information they need so they can pass it on down, and they have to put their due diligence and good faith forward to do that. It’s strongly suggested they document everything they do and when they did it so that, should OSHA visit, they would have that information available.”

KNOW YOUR SOURCES

Jon Melchi, vice president of government affairs and business development, Heating, Air-conditioning, and Refrigeration Distributors International (HARDI), said his organization is working to get the word out about the GHS.

“My biggest concern remains with distributors that don’t really play in the refrigerant chemical space,” Melchi told The NEWS. “They carry refrigerant as just another product because they don’t routinely purchase it from vendors, they may not be aware of what is out there or what the requirements are.”

Melchi added that he has spoken with a number of vendors that are doing their best to communicate the GHS throughout the channel but are finding it to be a challenging task.

“It’s a frustration for some folks, because it seems to be just another thing to do and keep track of,” Melchi said. “Some even question if anyone reads the labels. My answer to them is, ‘Well, one person reads the label for sure, and that’s your OSHA inspector, so you’d better do it.’”

Melchi concluded that partnering with respected suppliers and vendors can help make the transition to the GHS easier for contractors and distributors alike.

“When purchasing chemicals and refrigerant, it’s important to know your vendor so you can trust what’s in there,” he said. “Knowing the source of your refrigerant is important not only for you, so that the labeling is correct, but also for protecting your customer. The contractor in the field has to know everything is properly sourced. In our industry, we can’t play loose with chemicals and refrigerants. It’s too much of a risk for the contractor in the field and the consumer.”

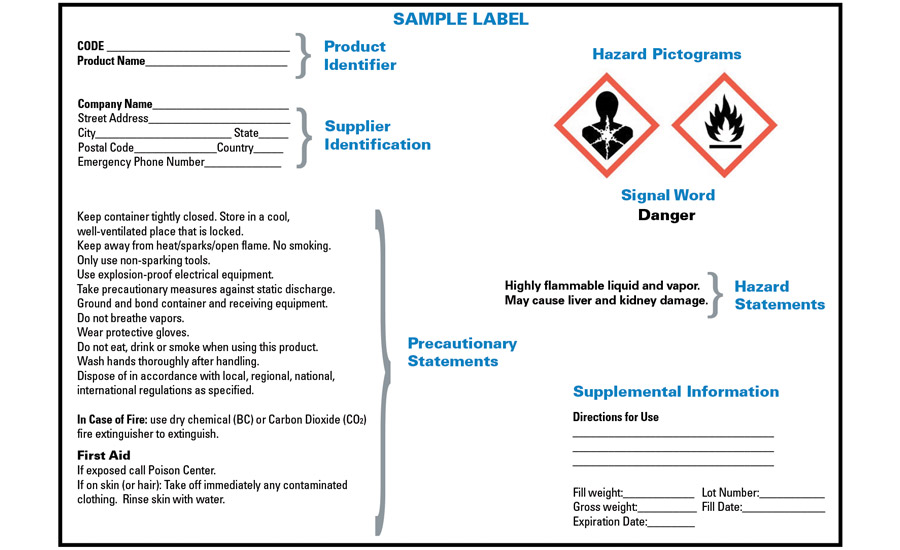

SIDEBAR: The GHS Shipped Container Label Elements

The Globally Harmonized System (GHS) revised Hazardous Communication System (HCS) provides a method for standardizing information for hazardous chemicals. As part of this revision, the Occupational Safety and Health Administration (OSHA) requires six label elements on containers that leave the workplace:

1. Product identifier;

2. Signal word;

3. Hazard statement(s);

4. Pictogram(s);

5. Precautionary statement(s); and

6. Name, address, and telephone number of the chemical manufacturer, importer, or other responsible party.

In addition, new safety data sheet (SDS) requirements establish a standardized order of information. According to OSHA, the harmonized 16-section format of the safety data sheets will enable employers, workers, health professionals, and emergency responders to access the information more efficiently and effectively, thus increasing their utility.

For more information, visit http://bit.ly/OSHA-refrigerants. Information about complying with the revised HCS is available on OSHA’s website, www.osha.gov. Links to several downloadable guidance publications are available at www.osha.gov/dsg/hazcom/index.html.

Publication date: 9/28/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment