EFFECTS OF WATER CONTAMINATION

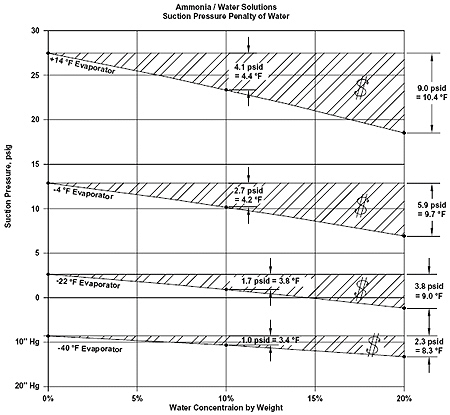

Water contamination in an industrial ammonia refrigeration system can lower system efficiency and increase the electrical costs required to run the system's refrigeration compressors.For a given pressure, the addition of water to the ammonia will raise its temperature. At typical suction pressures, the addition of 10 percent water by weight will increase the evaporator temperature by about 4°F (2°C).

Stated another way, for a given required evaporator temperature, the addition of water to the ammonia will require a lower suction pressure. For example, pure ammonia at -4°F (-20°C) has a saturation pressure of 12.9 psig (0.90 barg). An ammonia-water solution of 10 percent water and 90 percent ammonia by weight, at the same -4°F (-20°C) has a saturation pressure of 10.2 psig (0.72 barg). Therefore to maintain an evaporator temperature of -4°F (-20°C) in a system with 10 percent water contamination, the suction pressure would have to be run at 12.9 – 10.2 = 2.7 psi (0.18 bar) lower than if the water were not present.

Therefore, the extra energy required due to the 10 percent water concentration is (1.55-1.44)/1.44 = 7.6 percent.

The effect of air contamination in industrial refrigeration systems has been well documented over many years. Like water contamination, air contamination lowers system efficiency and increases electrical costs due to the higher compressor discharge pressure caused by the presence of the air. When the air is removed with a noncondensible gas purger (for example, a Hansen Auto-Purger) the discharge pressure is reduced, system efficiency is restored, and electrical costs are reduced.

The energy savings quickly pay for the cost of installing the noncondensible gas purger. Typically, there is a 6 percent savings in energy cost for every 10 psi (0.7 bar) of excess pressure due to noncondensible air that is removed from the refrigeration system.

OTHER BENEFITS OF PROPER MAINTENANCE OF REFRIGERANT QUALITY

Removing air and water from ammonia refrigeration systems certainly saves energy, but there are other benefits that improve system operation. On the high side of the system, operating at the lowest condensing pressure permissible means less wear and tear on compressor bearings and other mechanical parts. The lower discharge temperatures also reduce oil and refrigerant breakdown, and extend gasket life. Air removal means there is less oxygen in the system, which is sometimes associated with corrosion of piping and vessels. In the same way, removing water from the refrigeration system may reduce corrosion.MEANS OF WATER ENTRY INTO A SYSTEM

The most common way that water enters a system is with the air that enters the system. The air that enters the system has a certain relative humidity. Therefore, as air enters a system, a certain amount of moisture also enters the system.The moist air enters the system in two common ways: 1) For systems that operate in a vacuum, system leaks will pull moist air into the system through the leak path. 2) For all systems, regardless of whether they operate in a vacuum, if maintenance is performed on a portion of the system, and if this portion is not pulled into a strong vacuum before restoring it to service, that moist air remains in the system.

Noncondensible gas purgers are very effective at removing the air from the system. They are, however, less effective at removing the moisture from the system.

Another means of water entry into a system is when a water chiller develops a tube leak and water from the tube side mixes with the ammonia on the shell side, or vice versa. This can introduce large amounts of water to a system, and drastic measures may be required, including replacement of the entire refrigerant charge.

LOCATION WHERE WATER TYPICALLY COLLECTS

The ammonia, air, water, and oil circulate through the refrigeration system.Water will tend to collect on the low side of the system. Only gas can leave the low side of the system. Therefore water, for the most part, cannot leave the low side and will collect here. (Some water can leave as water vapor, but most will stay in the low side.) In two or more stage systems, the water will eventually collect in the lowest stage vessel.

The oil, also not being a gas, collects in the low side of the system, and must be routinely drained.

Alternatively, only liquid can exit the high side of the system, so air collects in the high side. This is typically near the outlet of evaporative condensers or in the coolest, low velocity section of receivers and water-cooled condensers.

REMOVAL OF WATER AND AIR FROM THE REFRIGERATION SYSTEM

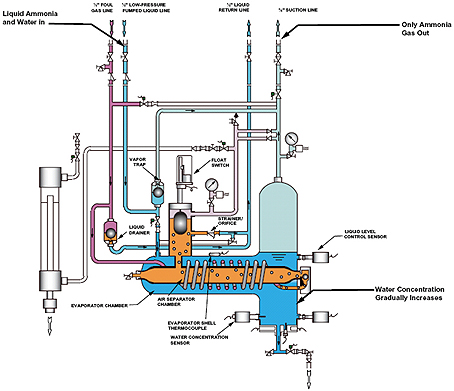

Hansen Technologies developed its automatic noncondensible gas purger over two decades ago. The Hansen Auto-Purger is designed to efficiently remove air from the high side of the system where air collects. Now Hansen has improved on the unit to add water removal capability. Models that have both water and air removal capabilities are called the Auto-Purger Plus.The Auto-Purger Plus removes air the same as the Auto-Purger model. An ammonia gas and air mixture (foul gas) is taken from various locations in the high side. This gas is brought into the tube side of a shell and tube heat exchanger with cold ammonia liquid on the shell side. The ammonia gas in the tube condenses to liquid. The air being noncondensible remains a gas. When enough air is collected, it is released.

See Figure 1.

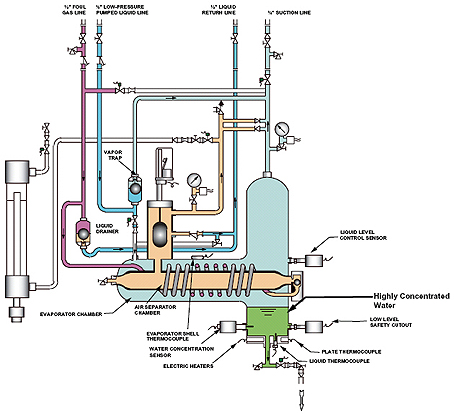

In the new Auto-Purger Plus model, the liquid is taken from the pump discharge of the lowest pressure recirculator. This is where we expect the water to collect. Only ammonia gas can exit the shell side of the heat exchanger. The concentration of water gradually increases over time as liquid ammonia and water are brought in, and only ammonia gas leaves.

See Figure 2.

See Figure 3.

After the water is drained, the Auto-Purger Plus goes back to normal operation collecting air and water. If no air or water is present, there are no releases to atmosphere.

CONCLUSION

Many industrial ammonia refrigeration systems contain significant amounts of water which reduces their efficiency. The removal of this water has not received sufficient attention in our industry. Removing the water with a unit such as the Hansen Auto-Purger Plus can restore system efficiency, reduce electrical costs, and save money.Ray Ficker, P.E., is with Hansen Technologies Corp., Burr Ridge, Ill. For more information, phone 630-325-1565, e-mail info@hantech.com, or visit www.hantech.com

Publication date: 04/17/2006

Report Abusive Comment