Bob arrives at the job and meets the homeowner. She explains to Bob that the furnace operated all night and stopped running in the early morning. She leads Bob to the basement where the furnace is located.

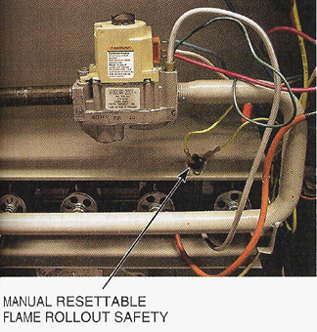

Bob checks the thermostat wires and sees that the thermostat is calling for heat, but the furnace is cold. He removes the cover to the burner section of the furnace and discovers that the burner section has a lot of soot where one of the burners is inserted into the heat exchanger. The burners are ribbon-type burners (Figure 1). The flame roll out protection control had tripped and had to be reset (Figure 2). When the burner starts up, the flame on that burner is yellow and rolling out the front of the burner hole in the heat exchanger. Bob tells the owner that the burners would have to be removed and the furnace cleaned before start-up.

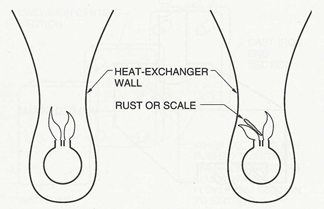

Bob turns off the gas and power to the furnace and begins to remove the burners. When he removes the burner that has the soot buildup, there are some large pieces of scale laying on the burner surface (Figure 3). Bob starts to think something is really wrong at this point. He has never seen this before. Btu Buddy shows up about this time and asks, "What is the question Bob?"

Btu Buddy explains, "It is likely that it is just surface rust and scale, but it will bear checking out. The reason for that rust may be from several possibilities. This furnace has electronic ignition so the pilot light does not burn all of the time. Sometimes with a standing pilot, that portion of the heat exchanger stays hot all of the time and rust will accumulate above the pilot where the pilot flue gas condenses on the heat exchanger. Since this is not a standing pilot, that is not a possibility.

"It could be that:

1. There may be solvents stored nearby. They will often cause the heat exchanger to corrode in large patches when the fumes are burned in the furnace flame.

2. If refrigerant from a long lasting leak has been induced into the burner section, it will corrode the heat exchanger.

3. If the basement where the furnace is located is damp, rust may eventually find a place to form under the coating on the heat exchanger.

"Use that as a checklist for excess heat exchanger scale and see what you find."

After removing the burners, Bob takes them out to the truck where he can blow them out with an air tank he carries. The burners are in good shape when he gets them cleaned. He takes them back in and uses his flashlight to look into the heat exchanger before starting to clean it. He says, "There seems to be a lot of soot in this one section where the scale was found." He removes the draft diverter so he can see down into the heat exchanger. There is some soot in the draft hood.

Btu Buddy says, "Put it back together and start it up, and see if the flame is stable. It would be a good idea to place your CO (carbon monoxide) detector above the heat exchanger to see if there is any CO present. However, I don't think you will find any."

Bob assembles the furnace and puts his detector probe above the heat exchanger and starts the furnace. Bob remarks, "The flame looks good. It is nice and blue." The fan starts and the furnace is performing correctly. The CO detector shows no sign of CO.

The homeowner comes back down to the basement about this time to question Bob. Bob explains that the furnace is getting older, but should last a few more years and suggests that it be inspected every fall because of the rust that is in the heat exchanger. The homeowner says, "Put me on your fall list for a furnace checkup and on the spring list for an air conditioner checkup. They are the same age, about 18 years old, but we would like to get some more years out of them if we can."

Bob says, "With some good maintenance work, they should be able to last about 25 years. The equipment is in good shape except for the rust and there is no serious damage done to the heat exchanger. May I ask, does the air conditioning system seem to require that refrigerant be added very often?"

The homeowner says, "Yes, we had refrigerant added every year until this past spring when one of your technicians found a leak on this line here at the furnace."

Bob responds, "That explains a lot. When refrigerant escapes near a flame, some of it will be drawn into the flame. This refrigerant turns into a mild acid when burned and that is what has caused the excess rust on the heat exchanger."

Bob puts his tools away and as they are riding away, he tells Btu Buddy, "It is really nice to find the answers to these puzzles. A little knowledge and experience goes a long way. Thanks for your help!"

Btu Buddy says, "Just keep learning and keep asking questions. Remember, you have two ears and one mouth. You can really learn more with your ears than your mouth. You did a great job with that customer. That question about refrigerant leaks was great. You also have great textbooks that can help you with a lot of these problems as well. The burner in that furnace was a rather old type burner. The new end-shot and up-shot burners do not protrude as far into the heat exchanger and are not subject to that kind of problem. Time and technology are marching on to new and better parts."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Delmar Publishers. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or bmj@myexcel.com.

Publication date: 01/24/2005

Report Abusive Comment