The dispatcher has called Bob with a no cooling service call. Actually, the unit had been cooling until last night when the home began to get warm inside.

Bob arrives and talks to the homeowner about the situation. She tells Bob that it was cool last night, but it began to get warmer in the early morning hours. The night outside temperature was 75°F so some cooling was needed.

Bob goes to the outside unit and finds that it is running, but the suction line is frozen back to the compressor. He decides that there must be restricted airflow or the system is low on refrigerant.

He then goes into the house and turns the compressor off and the fan to "fan on" to thaw out the coil. This will take about 30 minutes so he decides to check the rest of the system.

He determines that he'll check the filter first so he straps on his tool belt, takes a flashlight, and goes under the house to the air handler, which is a gas furnace. When he crawls to the furnace, he could here the indoor fan running and it sounds normal for a fan that is running against a coil that is frozen solid.

Bob shuts the unit off and removes the filter and discovers that it looks good. It had been changed recently. So he replaces it and starts the fan again to help thaw the coil. There is not much to do but wait until the coil thaws.

He goes in to the owner and explains what is happening and tells her that it is going to take time to thaw the coil and that he would go to lunch on that time.

After lunch, he returns to the job and finds that the coil has thawed and the system is ready to start up. He fastens gauges to the unit with a cylinder of refrigerant so he would be ready to add refrigerant to the system. About this time, Btu Buddy steps in and says, "Don't you think that you should do a little leak checking on the system before adding refrigerant? You may just have to take it all out again to repair a leak."

Bob says, "Good idea, the system seems to have plenty of pressure. It is not out of refrigerant, probably just low."

Bob goes to his truck for his electronic leak detector and then goes to all of the field connections on the outdoor unit but he could not find anything. He then crawls under the house and checks all of the connections at the coil. The piping at the coil is on the far side of the air handler, so he has to crawl around the duct to the piping side of the coil where the suction and liquid line and the condensate line are connected. He doesn't find any sign of a refrigerant leak on the piping connection or in the condensate line connection, so he comes back outside.

Btu Buddy asks, "What did you find?"

Bob explains, "I didn't find a leak, but I did find something a little strange. I had to dry the liquid line connection and the suction line connection. I can't figure out why the liquid line was wet. It was not under the suction line."

Btu Buddy says, "You may have discovered the problem, but I am going to let you figure it out. Start the system and see what the pressures are."

Bob starts the compressor from the inside thermostat and comes back outside as the pressures begin to register.

After a few minutes, Bob says, "The suction pressure is 70 psig and this is R-410A refrigerant. That equates to a 15 degree F temperature for the coil. This system is going to freeze again. It is definitely low on refrigerant. It is time to add refrigerant."

Btu Buddy then says, "Before you add refrigerant, go under the house and check that liquid line again. I will talk to you through the crawl space vent where the lines go through the foundation."

Bob goes under the house and finds the liquid line is freezing cold. He goes to the vent and tells Btu Buddy what he has found.

Btu Buddy tells Bob, "Follow the cold line back to this wall and see if you find anything."

Bob starts looking and then says, "There is a kink in the line about three feet from the wall. The freezing starts there."

Btu Buddy tells Bob, "Come out and let's talk about it."

A Kink In The Line

When Bob gets out from under the house, he says that someone must have been working under the house and must have pushed the line up next to the floor joists and bent the line. The bend or kink is not really severe, but must be repaired (Figure 1).Btu Buddy explains, "The kink in the line is a restriction just like the metering device. You now have two metering devices in series, a lot of pressure drop. The reason the coil and suction line froze was the low evaporator temperature made a block of ice out of the coil and it kept getting bigger until it was a solid block and the suction line froze."

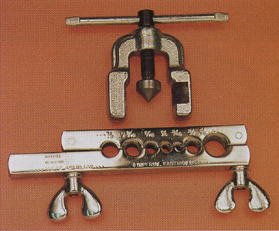

Btu Buddy tells Bob, "You have two choices: shut the system down and replace the bend with a coupling, or straighten the pipe out and use a flare block to round it out again. If you replace the bend with a coupling, you are going to need to recover the refrigerant to make the repair."

Bob goes and talks to the owner and explains the options. He explains that the rounded out pipe should last as long as the system and not be a problem as long as the pipe is not pushed around again.

The owner tells Bob that the cable repairman was under the house yesterday connecting cable to that part of the house and that is likely when the line was bent. She tells him to try to round the pipe, as that would be less expensive and they are tight for money at this time.

Bob then goes outside and turns the unit on again. The suction pressure then settles down to 142.5 psig, which corresponds to a 50 degree F coil. It is hot in the house. The pressure will come down as the house begins to cool down.

Bob writes up the report and goes in to the owner and says, "All looks well, I fastened that pipe up to protect it so this will not happen again."

She looks at the bill and says, "This is really fair for getting our system cooling again. Thank you."

Bob says, "It is not only just cooling, it is reliably cooling. It is going to last."

When driving away, Btu Buddy says, "That was a good job, at a reasonable price for the customer. All customers are looking for value and reliability in what they pay for. A job well done."

Bob says, "Thanks, it is good to see a customer that is happy."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Delmar Publishers. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or billj@carolina.rr.com.

Publication date: 09/19/2005

Report Abusive Comment