It’s hard to believe that football season is here. A tradition we have in the Richardson household is making homemade salsa on game day. My youngest son is head chef of this cooking adventure that started when he was much younger. As the years have passed, he’s gotten good at getting consistent results. However, his first attempt didn’t go so well. In his words, “It tasted funky!”

I remember hearing the disgust in his voice from the kitchen — we knew he needed help. So, it was time for a review of his recipe and ingredients. His taste test had proven something was off and he didn’t get the result he expected. With some investigation, we figured out the problem: He was missing an essential ingredient. With a little experimentation, we corrected the recipe, and he ultimately got the flavor just right. The experience was a great learning opportunity for him about paying attention to details.

Sometimes HVAC installations also don’t deliver the intended results. Is it possible they’re also missing ingredients, using a faulty recipe, or a combination of both? An installed HVAC system is kind of like salsa; it’s the finished product. The ingredients are the components used to assemble it, and the recipe includes your design and installation practices. Like salsa, if you mess up the ingredients or use a bad recipe, it could leave a bad taste in your customer’s mouth. Let’s look at some ways you can assure your installations pass the taste test.

Define Your Recipe

Before you can achieve great results, you first need to define your unique HVAC system recipe. If you don’t have one that’s proven, why not begin with a solid foundation? You can start with industry standards such as ACCA Manual J, S, and D, and manufacturer specifications. Once you determine your recipe, you can tweak it to suit your customer’s taste.

Parts of the HVAC system recipe to consider are:

- Your customer’s wants and needs

- Equipment sizing and selection

- Duct design and sizing

- Manufacturer specifications

- Code requirements

Each part of the recipe affects the ingredients you use and how they blend together. As you define and refine your recipe, focus your attention on the details. A recipe based on rules of thumb or opinions can be disastrous once put into action. It’s hard to repeat a “pinch of this” and a “pinch of that.” Many companies inadvertently sabotage their HVAC system recipes by making assumptions, like 6-inch ducts always deliver 100 cfm (cubic feet per minute) of airflow.

Once your recipe is complete, write the details down so you can repeat it. Then, make sure everyone in your company understands the importance of following it. The recipe must be simple, concise, and easy to follow. Otherwise, no one will use it.

Pay Attention to Ingredients

Once you determine and document your recipe, choose your ingredients. This step is currently the toughest because it’s hard to get many of the ingredients you need — they simply aren’t available. Be careful with your remaining options and keep your standards high.

Remember, these ingredients play a big part in a successful outcome. If you choose cheap ingredients, don’t add them in the right order, or leave one out, it will become painfully apparent. A great recipe with substandard ingredients results in a “funky” system.

Common HVAC system ingredients include:

- HVAC equipment

- Controls and safeties

- Refrigerant lines

- Condensate line

- The duct system

- Grilles and registers

For the best results, properly select and size the HVAC equipment to match the building load and assure adequate fan capacity. Size, install, and evacuate refrigerant lines according to manufacturer procedures. Terminate condensate lines and equip them with overflow safeties. Properly size the duct system and install it with low pressure-drop duct fittings, takeoffs, dampers, boots, and grilles and registers.

Each system component plays an important role in your customer’s comfort and overall system performance. Contrary to popular belief, the equipment is not the system. It is only an ingredient in the recipe that you create.

Multiple Cooks in the Kitchen

Multiple chefs determine a successful HVAC system installation. Be sure that everyone knows their role and how they affect the results delivered to your customers. This is much easier to write about than to put in practice.

System designers and salespeople often specify the recipe and the ingredients. If they recommend the wrong recipe or ingredients, they’re setting the installation team up for failure before they begin. Be sure your salespeople aren’t just grabbing the model number of the existing equipment and assuming the existing duct system works.

The installation team mixes the HVAC system ingredients to deliver the results. Do they understand the intended outcome and if they achieved it once they’re done? You can have the perfect recipe and ingredients, but if the individuals putting them together don’t know what they’re doing, the result will still taste awful.

Your team’s craftsmanship and attention to detail determine the outcome and whether your systems pass the taste test. As they assemble the ingredients, encourage them to slow down and pay attention. Haste often results in an ingredient being left out or misused.

Great Chefs Test

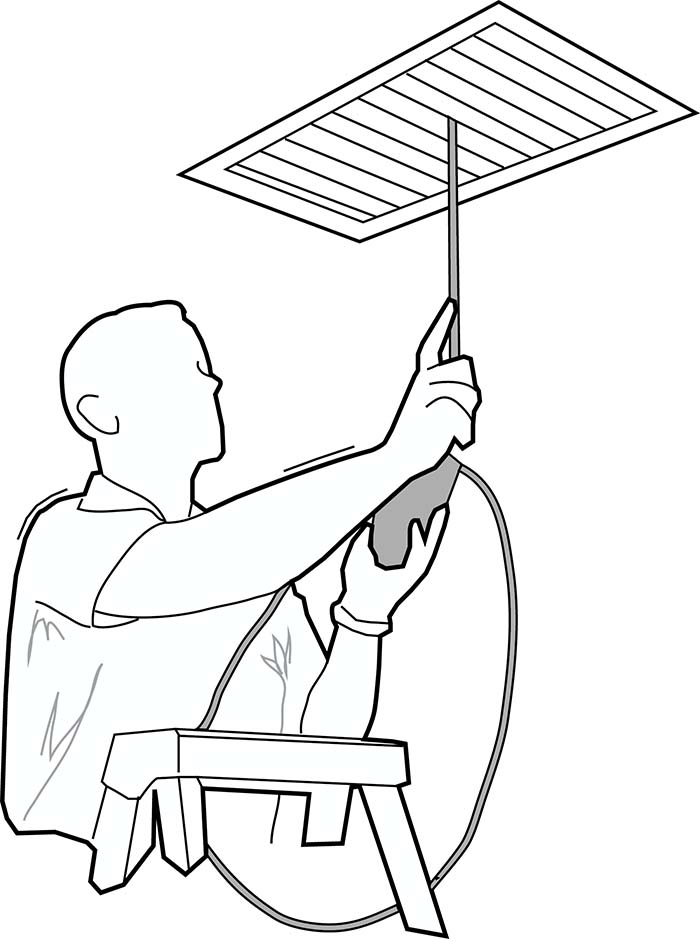

Measurements prove the recipe and ingredients work together correctly. (Courtesy of David Richardson)

You taste when you cook to confirm the recipe turns out as planned. For the same reason, you also need to test and verify your HVAC systems. Confirm the ingredients work together correctly. Testing ensures the system meets your approval and uncovers any missing recipe details and ingredients. If anything is off, you can correct it before it becomes a problem.

A skilled chef uses a variety of kitchen utensils to put a recipe together. They have the best gear they can afford to ensure their creation meets or exceeds expectations. Likewise, you’ll also want to have the right tools and test instruments. A good place to start is with a static pressure kit and digital psychrometer probes. Used correctly, this combination reveals a lot about an HVAC system.

What If Your System is Funky?

Sometimes your systems won’t work like you or your customers think they should. They’re funky, just like my son’s first salsa attempt. It’s possible you may have gotten too confident with your recipe and ingredients and failed to check the results.

If you find yourself with a funky system, follow the taste test approach. Start with some system tests and then use the test results to discover what’s missing. Static pressure, fan airflow, and temperatures are good places to start. They help you determine the “flavor” of your work.

Once you have your test readings, diagnose the system to find missing pieces and then add them. You don’t have to scrap everything if you know what to look for. We didn’t trash my son’s salsa; instead, we checked the recipe and fixed the missing ingredient.

Don’t just guess or use a hit-and-miss approach — the result might end up worse than what you started with. Remember, troubleshooting is the process of elimination. Identify what went into your HVAC system and then determine how well each ingredient performs. Once you find the missing or defective ingredient, fix it so your recipe is complete and your results improve.

There is a tremendous opportunity to provide your customers with the right ingredients and reliable recipes. The question is, can your chefs deliver the goods and prove it?

If you’re an HVAC professional interested in learning more about how to “taste test” an HVAC system, contact me at davidr@ncihvac.com or call 800-633-7058. NCI’s website www.nationalcomfortinstitute.com is full of free technical articles and downloads to help you improve your professionalism and strengthen your company.

Report Abusive Comment