We rarely buy anything without getting a receipt. Many of us save them for years because they prove we got what we paid for.

A receipt wasn't always an option. It wasn't until John Patterson bought the patent for the cash register and founded the National Cash Register Company in 1880 that the concept began. At first, acceptance of Patterson's new technology was slow. Store owners had a hard time seeing the value in his cash registers and were resistant to purchasing them.

To solve this problem, Patterson created a demand for the receipt instead of trying to sell store owners his cash register. He focused on the result of his product, not the product itself. This small shift in thinking changed how we do business in the United States. Let's look at what the HVAC industry can learn from this change in thinking and how you might apply it to your HVAC systems and business.

Your Product and Your Results

It's important to understand the difference between your product and your results. Have you ever considered the difference between the two? If you believe that HVAC equipment is your product, I think you're discounting the value you bring to the table. That's because HVAC equipment is not your product — you are!

Let's go one step further. The HVAC equipment is also not the HVAC system. If that sounds odd, think about the equipment for what it is — a selection of components you put together. Ten contractors can install the same equipment and each will have different outcomes. The product and the results are not the same.

You provide the HVAC system. How well it performs is a result of your product — that would be your skill and your craftsmanship. You combine your specialized skills and training to deliver the health, safety, comfort, and efficiency your customer expects.

Yellow Labels ARE NOT Receipts

There are standards in place to rate HVAC equipment efficiency in a laboratory environment. The yellow label showing the equipment’s AFUE or SEER rating is a receipt from the laboratory rating results under one set of test conditions.

Many professionals in our industry purchase equipment and assume that yellow label equals reality in the field. Unfortunately, laboratory-rated efficiency is not the same as field-installed efficiency. While they serve a purpose, yellow labels do not prove the craftsmanship of a field installation.

Remember, receipts are proof of purchase. We show the results of buying a product on them. So, what results are you trying to show?

If you're only concerned with equipment efficiency in a laboratory environment, then the yellow labels will work great for you. However, if you're looking to focus customers on your specialized skills, you'll need to look past equipment efficiency.

Our industry is missing a receipt for the final installation. We need the result of the assembled components plus each contractor’s craftsmanship.

The Need to Prove Craftsmanship

Since yellow labels don't prove installation skills, our industry needs a different approach. It requires measurements from the HVAC system to provide a craftsmanship receipt.

Anyone can look at an installation and tell if is sloppy or neat. But does it work like it's supposed to? Many of the aspects of craftsmanship are hidden, so we need a way to make them visible.

Tough Question: How does a customer know they got a quality installation if the only receipt they get is for the components and not the skill involved in assembling them?

Tougher Answer: They don't.

Our industry has much to offer customers. Unfortunately, it's easy to forget how special what we do is. Consider a few ways you provide craftsmanship:

- Industry best practices for design and installation

- Duct system material selection and installation

- Refrigerant line design and installation

- Purging with nitrogen while brazing

- Performing proper evacuation with a micron gauge

- Condensate line installation and drain protection

- Proper refrigerant charging practices

- Combustion safety testing of fuel-fired equipment

- Airflow testing and balancing.

These are a few of the things that most customers will never see. However, customers will notice the poor results if any of the above bullet points are missing or left out. Sometimes the results are instant; others may take years to appear.

I'm sure you can expand the list above, and I encourage you to do so. These hidden gems make you different. Isn't it time to make these principles visible through measurement and data instead of keeping them hidden?

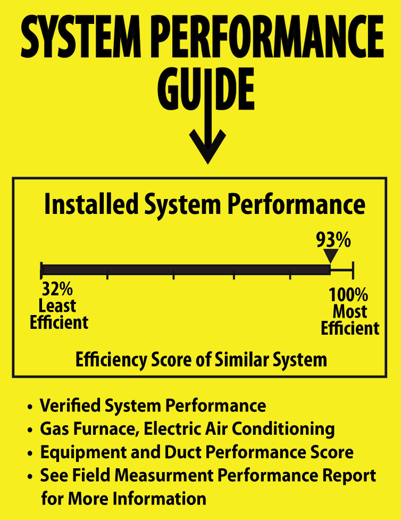

SYSTEM PERFORMANCE: Imagine offering your customers a craftsmanship receipt that prove the results of your work. You could use this simple metric to reveal an HVAC system’s efficiency based on real world conditions. Only the best work will pass the test. (Courtesy of David Richardson)

A Tale of Two HVAC Systems

During a recent private training session, we created two craftsmanship receipts. This company knew they did good work and were curious to see how well their systems performed. We found the perfect scenario — the home of one of the company's comfort advisors.

His home had two systems in it, and he had just moved in less than a year ago. The company had recently installed a 2-ton system conditioning an addition. There was another 4-ton system for the existing part of the house that had been installed by a competitor.

The 2-ton system installation looked great. We measured airflow from all the supply registers with a quality air balancing hood and totaled up the airflow feeding the area. Next, we measured the enthalpy change across the system at the supply registers and return grilles with Bluetooth psychrometer probes.

We combined these readings to determine how many cooling Btus the system was delivering into the conditioned space. Once we knew the delivered Btus, we divided them by the equipment's rated cooling Btus under the conditions we tested. This step showed us how well the installation performed.

The comfort advisor and installation manager were both pleased to find that their system delivered about 95% of the equipment's laboratory-rated capacity. It takes an extraordinary installation to achieve a system performance score over 90%. The craftsmanship receipt proved they installed exactly what they said they would, and we proved it through measurements.

Next, it was time to test the 4-ton system installed by the competition. We followed the same process of measuring airflow and enthalpy change across the system to determine the delivered Btus from the cooling system into the conditioned space. This time, our results weren't as flattering.

Instead of delivering close to 4 tons of cooling into the comfort advisor's home, it only delivered around 2.75 tons of cooling. This system was only operating at 66% of the laboratory-rated capacity. The craftsmanship receipt revealed a system that failed to deliver what was sold.

The measurements of these systems were proof of their design and workmanship. One system passed with flying colors. The results on the company’s installation were proof that everything came together to achieve a great HVAC system. However, the other system failed to deliver.

The Results of Your Product

If you or someone else were to test your work and provide a craftsmanship receipt, what would it show? Would it prove your work resulted in what you promised, or would it tell another story?

Our industry must be about far more than dealers peddling equipment for the lowest price. We affect the quality of people's lives. Don't forget that your work makes a difference. If you're tired of looking and sounding like everyone else, it might be time for you to provide proof of your work.

Your customers need to know there is a way for them to receive proof that what they paid for is what you delivered. You can prove your installations are better through measurements. Unless you measure, you can't provide a craftsmanship receipt and you're stuck playing the same low-bid game that everyone else is struggling to win.

It's time for our industry to change the game like John Patterson did. He focused on the results of his product, not the product itself. Why not focus on your strengths and offer proof of the results to your customers?

Report Abusive Comment