The lubricant in refrigeration and air conditioning systems has many important functions. Even though the circulated refrigerant is the working fluid required for cooling, the lubricant or oil is needed for lubrication of the compressor’s moving mechanical parts.

Oil minimizes mechanical wear by reducing friction. Oil also maintains a seal between the high and low side of the compressor. Without proper lubrication, the compressor’s valves, mating scrolls, screws, and vanes would not properly seal. The results would be high-side refrigerant pressures entering the low side of the refrigeration system. Piston rings in a reciprocating compressor and rotating vanes in centrifugal compressors rely on the lubricating oil to prevent blow-by around the pistons and vanes. Oil also acts as a noise dampener within the compressor and transfers heat away from moving and rotating parts within the compressor.

Oiling System

Refrigeration and air conditioning compressors that contain an oil pump located at the end of their crankshafts are considered to have a forced oiling system. The crankshaft is connected to the oil pump and supplies power, which turns the oil pump. The oil pump is actually keyed into the compressor’s crankshaft. Oil pumps force oil through drilled holes or oil galleys in the crankshaft and deliver it to bearings, connecting rods, and often a tube and fin oil cooler.

Oil pumps can be of the gear or eccentric type. Gear-type oil pumps usually have a star gear that squeezes the oil to a higher pressure. Eccentric-type oil pumps use an eccentric type of mechanism to also squeeze the oil into a smaller and smaller volume, which adds pressure to the oil. This added pressure is referred to as net oil pressure.

Smaller HVACR compressors usually have some sort of splash-type oiling system. These systems may have an oil scoop that scoops and flings the oil throughout the crankcase, causing an oil fog as the crankshaft rotates. In both small and large systems, the oil then drops to the crankcase to be filtered and picked up again by the oil pump or splashing mechanism. Under ideal conditions, oil is designed to stay in the compressor’s crankcase; however, ideal conditions rarely exist in the real world, which means that there will be oil that escapes the compressor’s crankcase and enters the system’s piping. This escaped oil must be eventually returned to the compressor’s crankcase or system restrictions, breakdowns, and inefficiencies will occur.

Under normal conditions, there will always be a small amount of oil that escapes a compressor’s crankcase and is circulated with the refrigerant throughout the piping system. It is for this reason that refrigerant oil and the refrigerant itself must be soluble in one another. It is the velocity of the circulated refrigerant that carries the oil back to the compressor’s crankcase. If the two were not soluble in one another, this phenomenon could not happen. This is why line, coil, and valve sizing are critical to maintaining the refrigerant velocity required for proper oil return.

Refrigerant Migration

During a compressor’s off cycle, and especially during a long shutdown, refrigerant will want to travel or migrate to a place where the pressure is the lowest. Refrigerant migration is defined as refrigerant, either liquid or vapor, traveling to the compressor’s suction line or crankcase during the off-cycle.

The crankcase usually has a lower pressure than the evaporator because of the oil it contains. Refrigeration oil has a very low vapor pressure, and refrigerant will flow to it whether the refrigerant is in the vapor or liquid state. If the oil did not have a very low vapor pressure, it would vaporize every time a low pressure existed in the crankcase or when a vacuum was pulled on the crankcase.

Because refrigeration migration can occur with refrigerant vapor, the migration can occur uphill or downhill. When the refrigerant vapor reaches the crankcase, it will be absorbed and condense in the oil. Once this phenomenon happens, the liquid refrigerant will be on the bottom of the oil in the crankcase because it is heavier than the oil.

When the compressor is finally turned on after a long off-cycle or shutdown, or cycled on, the sudden crankcase pressure drop will cause the oil and refrigerant mixture in the crankcase to flash. The oil level in the crankcase will then drop, and mechanical parts can be scored. Oil foaming will appear, and a combination of oil and refrigerant can be forced around piston rings and pumped by the compressor into the piping system. High current draws, motor overheating, and broken valves can occur. Also, the oil that escaped the crankcase and entered the piping system now has to be returned to the compressor’s crankcase to maintain a healthy oil level in the crankcase.

If the compressor is located in a cold ambient, migration will take place even faster, because a cold ambient will cause an even lower vapor pressure in the compressor's crankcase. Migration will even take place from a suction line accumulator to a compressor because of the difference in vapor pressure.

Oil Logging

Once the oil is in the piping system, it will have a tendency to log or accumulate in low points within the system piping. Another popular area for oil to accumulate is in the evaporator, because it is the coldest component with the largest tubes, thus the slowest refrigerant velocity. Oil logged in the evaporator will coat the inner wall of the coil and reduce the heat transfer through the walls, causing a loss of capacity and poor performance. The compressor will be robbed of some of its crankcase oil and run with a lower than normal oil level, which may score or ruin mechanical parts in the compressor.

Too high of a viscosity oil will also be hard to return from an evaporator and will surely cause oil logging. Usually, the heat from the defrost heaters will warm and thin the oil in the evaporator so it can be returned to the compressor once the compressor starts up. This will happen only if the right viscosity (thickness) of oil is used.

If a suction line is oversized, the refrigerant velocity will be decreased. This will prevent the oil from moving through the suction line to the compressor’s crankcase. Remember, it is the refrigerant velocity that will move the oil through the refrigeration system’s piping. Listed below are ways an evaporator can become oil logged:

- Not enough defrost periods for low-temperature application machines (defrosts help return oil by heating and thinning the oil);

- Liquid migration during off cycle, causing crankcase oil foaming on startups;

- A flooded compressor circulating oil at startup;

- Too much oil in the system;

- System not piped correctly;

- System piping too large (oversized);

- TXV out of adjustment (too little superheat causing a refrigerant-flooded compressor with refrigerant boiling in the crankcase with the oil);

- Wrong type or viscosity of oil (oil that is too thick will congregate in system piping); and

- No oil traps.

Oil Traps

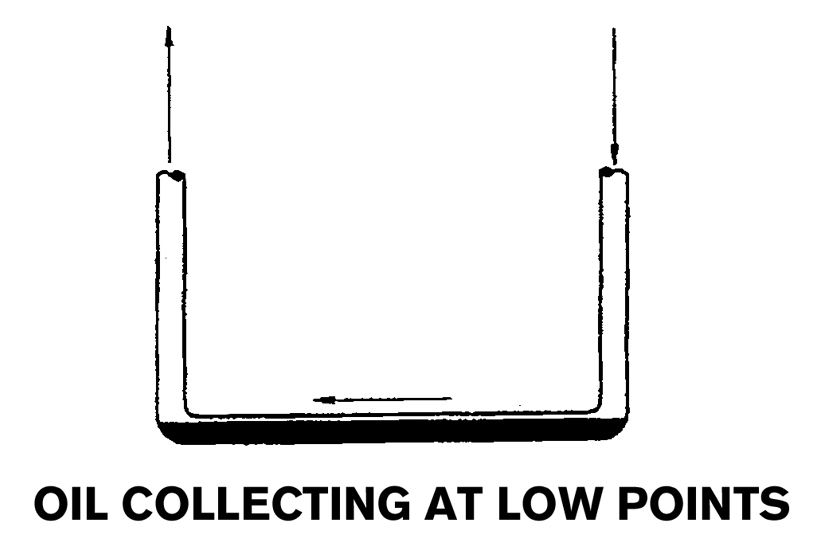

Often, systems without good oil separators or none at all, will have oil buildup points throughout the piping (see Figure 1). As mentioned earlier, refrigerant and oil mix with one another when used properly in a refrigeration or air conditioning system, and the fine oil mist that travels with the refrigerant will usually build up and collect at low points and risers in the system's piping. Some of the time, the refrigerant vapor will push this slug of oil to the next low spot, until the oil finally returns to the compressor.

FIGURE 1: Systems without good oil separators or none at all, will have oil buildup points throughout the piping. (Courtesy of John Tomczyk)

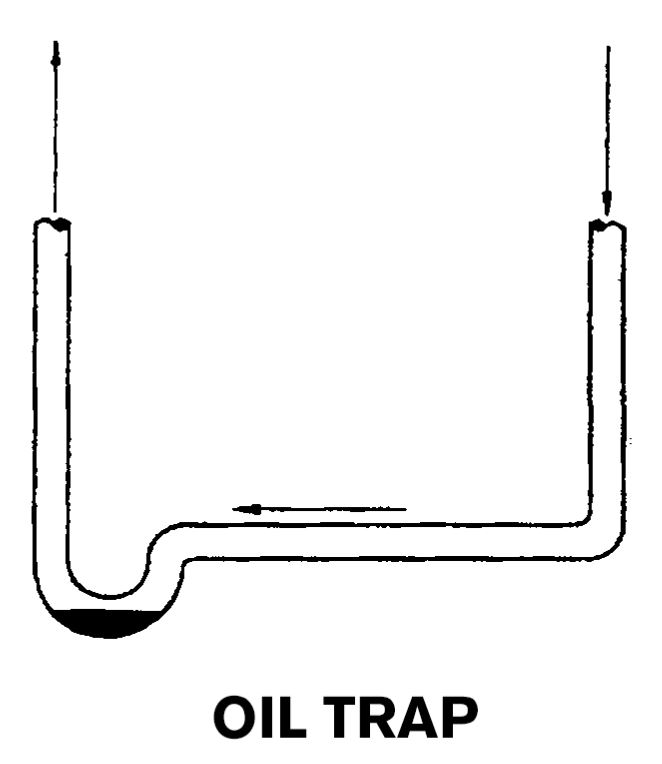

Large oil slugs returning to some compressor can damage valve plates and internal running gear if hydraulic pressure builds too great in the cylinders. To prevent this from happening, oil traps are needed in the system piping (see Figure 2). The function of an oil trap is to prevent large oil slugs from forming. This is accomplished by trapping a small amount of oil in the trap and gradually returning it to the compressor.

FIGURE 2: The function of an oil trap is to prevent large oil slugs from forming. (Courtesy of John Tomczyk)

As noted above, it is the velocity of the refrigerant that carries oil throughout a refrigeration and air conditioning system. As oil clings to the sidewalls of the piping, refrigerant gas velocity sweeps small oil particles away in suspension. This is why refrigeration and/or air conditioning piping should never be oversized. Oversized piping will slow refrigerant velocities down, causing poor oil return.

As oil collects in the trap (Figure 2), there is a restriction of internal pipe area. This causes the refrigerant gas to travel faster as it passes by the oil accumulated in the trap. It is this higher velocity refrigerant that will pick up minute surface droplets of oil out of the trap. The small oil droplets will then be carried either to the compressor, or to the next oil trap. Oil traps are constantly being fed and depleted of oil at a gradual rate, which protects compressors from large oil slugs. It is recommended that there be oil traps in all vapor-carrying lines in the system to ensure proper oil return.

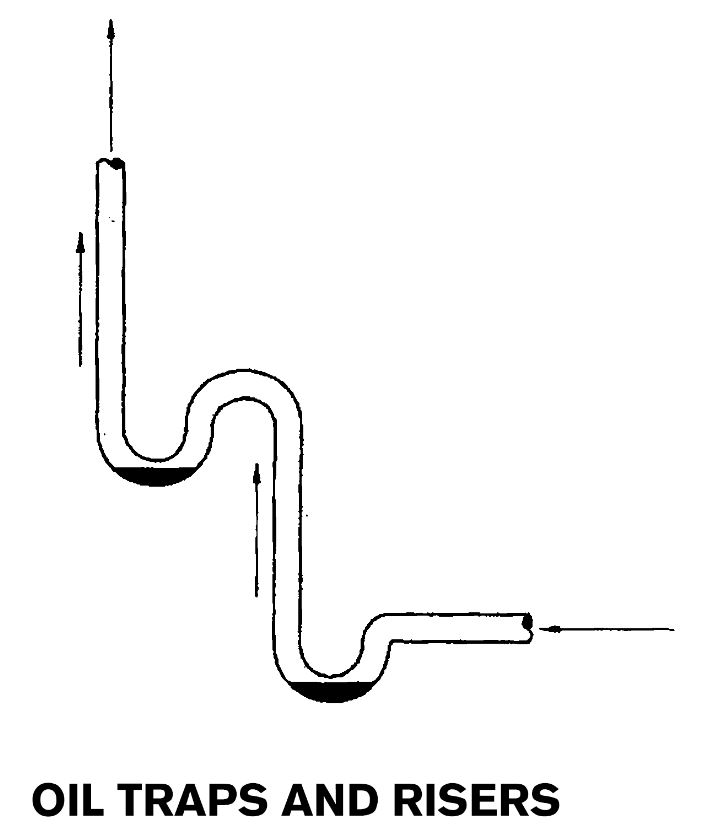

Vertical or upward runs of piping — called risers — cause the refrigerant to flow upward. If there is oil mixed in with the refrigerant, it will have a tendency to fall back to the bottom of the riser because of the long climb to the top of the riser fighting gravity all the way. This is why there should be a trap at the bottom of the riser. There should also be an oil trap every 15 to 20 feet of riser to help temporarily store the oil as it makes its way to the top of the riser (see Figure 3). This is because the refrigerant/oil mixture gradually loses velocity as it climbs the riser.

FIGURE 3: There should also be an oil trap every 15 to 20 feet of riser to help temporarily store the oil as it makes its way to the top of the riser. (Courtesy of John Tomczyk)

Report Abusive Comment