For the layman, the term “smart technology” likely conjures up images of smart thermostats, smartphones, and other popular consumer products. However, smart technology — as many HVAC contractors already know — has reached into the commercial sector as well. Now, commercial rooftop units (RTUs) feature a host of intelligent solutions to improve efficiency and ease of service/installation.

Intelligent Technologies in the Rooftop

“Smart technologies offer intelligence in all aspects of the rooftop: the compression, expansion, safety, and the reliability of the unit,” said Sankar Padhmanabhan, Danfoss global application expert of rooftop and packaged systems. In rooftop unit compression, variable-speed technology allows the unit to match the load from the building, instead of repeatedly having to cycle on/off at full power. Intelligence built into the controller allows the unit to communicate with apps, Bluetooth, wireless technologies, and more.

“Intelligence technologies result in better efficiency, better reliability, ease of maintenance, and real-time monitoring,” said Padhmanabhan. He also explained that smart rooftop units incorporate electronic expansion valves, which results in a valve that can directly control the superheat, leading to energy savings. In addition to this, an electronic valve can be opened or closed as determined by the system controller instead of being dependent on thermal characteristics of the heat exchanger.

FOUR ASPECTS: “Smart technologies offer intelligence in all aspects of the rooftop: The compression, expansion, safety, and the reliability of the unity,” said Sankar Padhmanabhan, Danfoss global application expert.

Padhmanabhan explained that sensor technology will help maintain safety as A2L refrigerants become more common in the industry. RTU systems incorporate sensors to detect basic information such as pressure/temperature of the system and make intelligent decisions using that data. They will also have built-in leak detectors as A2L refrigerants are implemented. The leak detectors will not only identify leaks but will then automatically send signals to take mitigating actions, such as turning off the compressor and turning the fans on for enhanced ventilation.

In addition, sensors aid servicing and troubleshooting RTU units when problems arise.

“In the past, the technician may have had to go somewhere to log in to the controller, get the data, look at it, and maybe look up some very weird error codes,” Padhmanabhan said. “But now, the service guy can be anywhere. He can be in his app, monitoring what is going on with the units.”

This is compounded by an intelligent RTU’s ability to send notifications and warning messages when something goes wrong with the unit, allowing preventive maintenance before something worse happens.

“The end user gets a better rooftop, which is highly performing, reliable, and safe to operate,” said Padhmanabhan.

Benefits of RTU Controllers

Philip Smyth, director of commercial product management, Johnson Controls, also spoke about the ability for rooftop units to use their controllers to connect with smart devices and phones.

Smyth said that Johnson Controls’ units offer startup and commissioning wizards to further aid in the RTU startup process.

“More and more people are looking for remote access so that they can remotely troubleshoot units. That way, they can understand when a failure is imminent, rather than going on periodic maintenance calls,” said Smyth.

In addition to this, he said that Johnson Controls’ units offer startup and commissioning wizards to further aid in the RTU startup process.

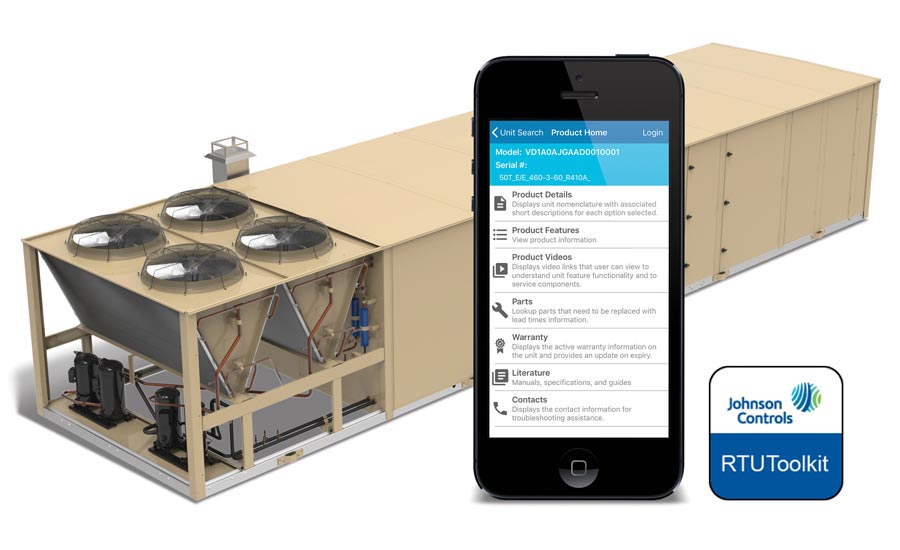

“When you first start up a unit, you want to make sure that you do that in a logical sequence so that you don’t harm the unit,” he said. “Johnson Controls’ new RTUToolkit startup wizard helps with that.”

The air balancing wizard helps to turn on fans, actuate dampers, and ensure that a building is balanced from an air distribution perspective. The commissioning wizard helps integrate the RTU with a building automation system (BAS). Plus, QR codes on units can pull up the RTUToolkit on smartphones that helps technicians understand the specific components they are looking at and servicing. The toolkit can help identify the devices incorporated into the RTU, and it can also walk the technician step-by-step through one device.

Matt Schlegel, commercial product manager for Johnson Controls, said that smart technology and its ability to integrate with building automation systems is a critical part of the industry today.

“If you’re the building owner or facility manager, you simply pull out your phone and connect to the Wi-Fi signal to have direct control over your rooftop unit,” said Schlegel. “But it expands beyond that, because you can go in a larger building with multiple rooftop units and tie them all together, and access each of those units through that Wi-Fi setup.”

Smyth said that Johnson Controls uses intelligent technology to make RTUs as user-friendly as possible. It’s important that the equipment easily connect with smart devices, and that the user interface for viewing the equipment data is intuitive to ensure easier installation and ongoing maintenance. Plus, Schlegel said, remote monitoring allows contractors to be more efficient, since some troubleshooting can be done before they get to the jobsite to ensure that they bring the correct tools or replacement parts with them to avoid a second trip. Furthermore, he said that remote monitoring allows contractors to understand when failure is imminent instead of relying on reactive or time-based maintenance, offering peace of mind and savings to the consumer.

“This intelligent technology allows contractors to shut down a unit if necessary before it reaches a catastrophic failure, which contributes to the longevity of the machines,” said Smyth. “We establish reasonable operating parameters and don’t allow the machine to operate in areas that would be detrimental.” Smyth also said that since more data points are being monitored and alerts can be set to identify simpler issues such as dirty filters, owners can ensure that energy consumption is as low as possible.

Remote Monitoring

Mitul Lakdawala, light commercial product manager for Daikin North America LLC, said that direct digital controllers will provide intelligence with capabilities such as system status, monitoring, control, and diagnosis. This helps equipment reach optimal operation as well as proper building occupant comfort.

“Keeping the equipment operating at optimal performance provides the end user with optimal comfort and optimal energy usage,” said Lakdawala. “Remote monitoring and diagnostics can minimize unnecessary service calls and the number of trips to the jobsite for the technician — all of which provides greater return on investment to the end user.”

Lakdawala also explained that intelligent technologies allow technicians to review data, diagnose the unit from anywhere using the graphic web interface, and review operating and alarm history.

“The remote monitoring provides a quick and easy equipment diagnosis, saving time for the technician and cost for the end user,” said Lakdawala.

IAQ SOLUTION: Rosa Leal, senior product manager for Rheem, said that the Commercial Renaissance Package Units are designed to keep air healthy for inhabitants, making it useful for applications like classrooms, healthcare, and conference centers.

Rooftop Units and Indoor Air Quality

Rosa Leal, senior product manager for Rheem, explained that commercial package units can benefit a location’s air quality as well — citing Rheem’s Commercial Renaissance Package Unit’s humidity control features as an example of this. Products like this also use economizers to regulate indoor air quality and fresh air requirements for cooling opportunities.

Report Abusive Comment