There are varying types of symptoms that can occur when a refrigeration system has an overcharge of refrigerant, and these symptoms vary depending on the type of metering device used. These are the typical symptoms for an overcharged refrigeration system with a conventional thermostatic expansion valve (TXV) as the metering device:

- High discharge temperatures

- High condenser subcooling

- High condensing pressure

- Higher condenser splits

- Slightly higher evaporator pressures

It is helpful to analyze each of the symptoms separately.

High discharge temperatures: Liquid backed up in the condenser from the overcharge of refrigerant will flood some of the condenser’s internal volume at its bottom, causing high head pressures. All of the heat being absorbed in the evaporator and the suction line, along with motor heat and high heat of compression from the high compression ratio, causes high compressor discharge temperatures. This heat has to be rejected into a smaller condenser’s internal volume because of the backed up (overcharged) liquid refrigerant.

High condenser subcooling: Because there is too much refrigerant in the system, the condenser will have too much liquid backed up at its bottom, causing high subcooling. Remember, any liquid in the condenser lower than the condensing temperature is considered subcooling. Condenser subcooling is an excellent indicator of the system's refrigerant charge: the lower the refrigerant charge, the lower the subcooling, and the higher the refrigerant charge, the higher the subcooling.

High condensing pressures: Subcooled liquid backed up in the condenser will cause a reduced condenser internal volume and raise condensing pressures.

High condenser splits: Because of the higher condensing pressures, and thus higher condensing temperatures, there will be a greater temperature difference (split) between the ambient and condensing temperature. A dirty condenser will also give a system high condenser splits, but the condenser subcooling will not be as high as with an overcharged system. Remember, the condenser split is the difference between the condensing temperature and the ambient temperature.

Slightly higher evaporator pressures: In this system, the TXV will still try to maintain its evaporator superheat, and the evaporator pressure will be slightly high depending on the amount of overcharge. If the refrigerant overcharge is excessive, the evaporator's higher pressure would be caused by the decreased mass flow rate through the compressor from high compression ratios causing low volumetric efficiencies. The evaporator would have a harder time keeping up with the higher heat loads from the warmer entering-air temperature. The TXV will also have a tendency to overfeed refrigerant to the evaporator on its opening stroke due to the high head pressures.

The function of a conventional TXV is to simply control evaporator superheat under all heat loading conditions — it does not have any control over changing evaporator pressures caused from varying heat loads on the evaporator. TXV systems allow evaporator pressures to rise a bit when the system is overcharged because of a lower system capacity when the condensing pressure rises from the overcharged system. This rise in condensing pressure causes a higher compression ratio, and thus a lower volumetric efficiency, which will cause the refrigerated space temperature to rise. An extremely high condensing pressure may also be out of the operating pressure range of the TXV, so the TXV may overfeed the evaporator with liquid refrigerant and cause higher evaporator pressures.

Automatic Expansion Valve

What if the system has an automatic expansion valve (AXV) as the metering device? Listed below are the symptoms for an overcharge of refrigerant with a system incorporating an AXV:

- High discharge temperatures

- High condenser subcooling

- High condensing pressure

- High condenser splits

- Normal evaporator pressures

Notice that the only difference in symptoms for an overcharged system between a TXV and an AXV metering device is in the evaporator pressure. The evaporator pressure is normal for the AXV and high for the TXV when the system is overcharged. In this case, the AXV holds a constant evaporator pressure even when the system is overcharged with refrigerant.

Figure 1 is a cut-away illustration of an AXV. The two forces that throttle the AXV open and closed are the spring and the evaporator pressures. The evaporator pressure is a closing force, and the spring pressure is an opening force. The valve stem or adjustment screw should be adjusted for the desired evaporator pressure.

Click diagram to enlarge.

FIGURE 1: Cutaway view of an automatic expansion valve (AXV).

The function of an AXV is to hold a constant evaporator pressure no matter what the system conditions are. It does this by either starving or feeding the evaporator with refrigerant in response to the slightest change in evaporator pressures. In order to keep a constant pressure in the evaporator, the rate of refrigerant vaporizing in the evaporator must be kept constant under all evaporator heat loading conditions.

At high evaporator heat loads, the refrigerant delivered to the evaporator will be decreased by the AXV. This action happens because of the increased rate of refrigerant vaporization in the evaporator, causing a higher evaporator pressure. With evaporator pressure being a closing force, this higher evaporator pressure will throttle the valve in the closing direction, thus decreasing the amount of refrigerant metered into the evaporator. This decreased amount of refrigerant will cause a somewhat inactive evaporator with a lot of superheat; however, a constant evaporator pressure is maintained (see Figure 2).

Click diagram to enlarge.

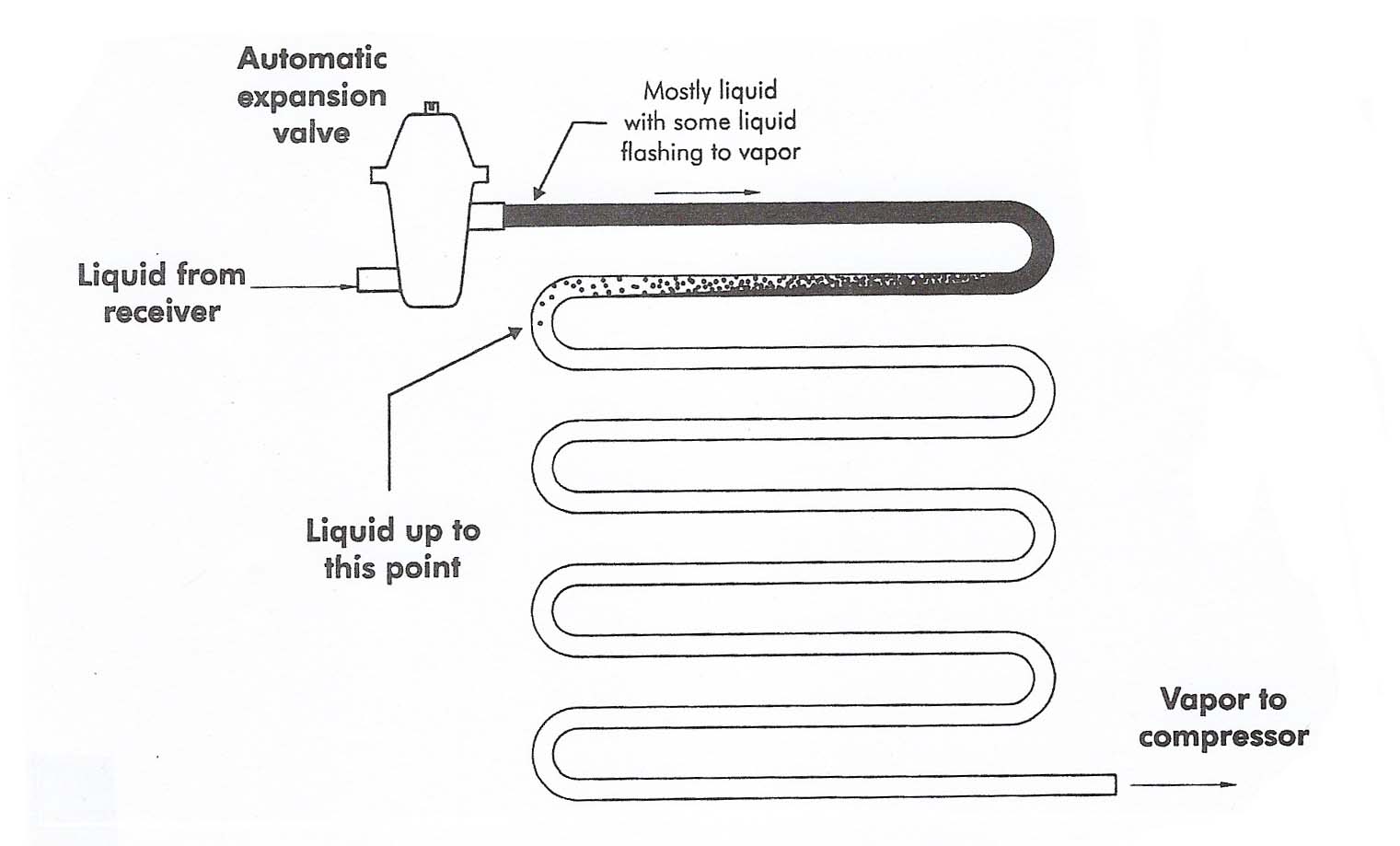

FIGURE 2: An AXV causing an inactive evaporator in order to hold a constant evaporator pressure.

The opposite happens when the evaporator experiences a low heat loading. Because the AXV will often starve an evaporator in order to keep a constant pressure, its efficiency is considered poor when compared to other metering devices. Also, because of the AXV’s constant pressure characteristics, it cannot be used with a pressure-type motor controller.

Capillary Tube

What if the system has a capillary tube as the metering device? Listed below are symptoms for a capillary tube system when overcharged with refrigerant:

- High discharge temperatures (unless wet compression takes place)

- High condenser subcooling

- High condensing pressure

- High condenser splits

- Much higher evaporator pressures

Again, the only difference in symptoms when compared to a conventional TXV system is the evaporator pressure. When overcharged, the capillary tube system will run a much higher evaporator pressure than a conventional TXV system that is overcharged.

Capillary tube systems are usually copper tubes with a small inside diameter and are used in critically charged refrigeration systems. How much refrigerant will blow through the capillary tube depends on the pressure difference across the tube, the inside diameter of the tube, and its length.

Capillary tube systems do not control evaporator superheat or evaporator pressure. They are usually used where the heat load on the evaporator is relatively constant; however, any liquid refrigerant in excess of the capillary tubes critical charge will be backed up in the condenser. This will cause less condenser internal volume to desuperheat, condense, and subcool the refrigerant in the condenser. The condenser pressure will then rise, pushing more liquid from the bottom of the condenser through the capillary tube to overfeed the evaporator. This causes much higher evaporator pressures.

If the rise of condensing pressure is severe enough, an enormous amount of subcooled liquid from the bottom of the condenser will be pushed through the capillary tube, causing flooding of the crankcase or slugging in the compressor’s cylinder. When the compressor slugs liquid, wet compression takes place, and the discharge temperature will be much cooler than normal. This happens because as the liquid droplets of refrigerant vaporize in the cylinder of the compressor on the upstroke, they absorb tremendous amounts of heat from the cylinder walls and from the heat of compression, which gives a lower discharge temperature. In severe slugging cases, the discharge temperature is often lower than the condensing temperature.

Report Abusive Comment