In supermarkets, humidity not only impacts energy savings and customer comfort, but it also can have a major effect on the performance of a store’s refrigeration equipment.

At a recent Food Marketing Institute (FMI) Energy and Store Development conference, Abtar Singh, president, Singh360, a facility management consulting firm, noted that in addition to customer comfort, humidity may impact a supermarket in a number of ways, including:

- Product display — Frosting of frequently opened glass refrigerated case doors can hinder product visibility and attractiveness;

- Safety and health — Condensation dripping from glass case doors can cause a slip hazard, and high humidity in refrigerated cases can lead to the growth of fungus and mold;

- Increased maintenance — Floor cleanups and iced coils can create additional maintenance work for supermarket personnel and corrosion and rust may decrease the asset’s life;

- Increased energy consumption — In addition to the HVAC energy costs for dehumidification, high humidity can increase refrigeration energy usage for defrosting and cause a high door heater run rate.

Singh noted that keeping a store’s dehumidification set point high reduces energy use via the dehumidification unit (DHU) but increases energy consumption in the door heaters and refrigeration system. Lowering the store’s dehumidification set point, on the other hand, will help the refrigeration system to run more efficiently but will require the DHU to run harder.

“It is always better to remove moisture using the DHU rather than at the refrigerated coils,” Singh said. “The EERs of DHUs are typically around 10 while refrigeration equipment typically has EERs of 3-5.”

USE DEW POINT INSTEAD OF RH CONTROL

When seeking to control humidity in a supermarket, Singh advised that dew point is a better parameter to control than relative humidity. Dew point does not change with temperature and will indicate the true moisture content in a supermarket’s air. Although it can be difficult to measure using sensors, building management systems typically can convert dry-bulb temperature and relative humidity percentage to dew point.

To minimize sweating, Singh noted the door temperature of the refrigerated cases needs to be greater than the dew point temperature of the store’s air.

What is the optimum dew point? According to Singh, refrigerated cases are designed for 75°F dry bulb temperature and 55 percent relative humidity, which is 57° dew point. Human comfort requires 70°-76° dry bulb temperature and 47°-57° dew point temp.

“A lower dew point is better for refrigerated cases but may increase HVAC power consumption,” Singh said. “And there is an optimum dew point for every store format based on door type and heater amperage, number of open cases versus closed cases, and percent of floor space covered by refrigerated cases. Generally, a good starting point is 74° dry bulb temperature and 51°- 53° dew point.”

WHAT AFFECTS HUMIDITY IN STORES?

A number of factors can affect the humidity level in a supermarket. The first is infiltration.

“The amount of air exhausted needs to be brought through a DHU to maintain a positive pressure; otherwise, untreated air will enter from the front doors and receiving area,” Singh said. “In addition, watch out for compressor rooms inside the store. If they’re not sealed, the exhaust fans will pull treated air from the store, which will cause negative building pressures.”

There are three basic methods of dehumidification in a store: DX cooling, a desiccant system, or a combination of the two. Whichever method is selected, proper operation of the DHU is essential for good humidity control.

Issues may arise, including a faulty DHU, which could be caused by a compressor issue, low refrigerant charge, a misadjusted thermal expansion valve, etc. Additional issues may include a night setback that’s based on time and dry-bulb temperature rather than moisture content (dew point), on-off delays if a DX DHU is used, or reheat.

Pay particular attention to reheat, because it can help prevent condensation in ducts by keeping the duct temperature above the store’s dew point temperature as well as allow a store’s air to grab and hold more moisture: Keep in mind that a larger temperature difference across the DX coil (air dew point temperature minus coil temperature) can help the system extract more moisture.

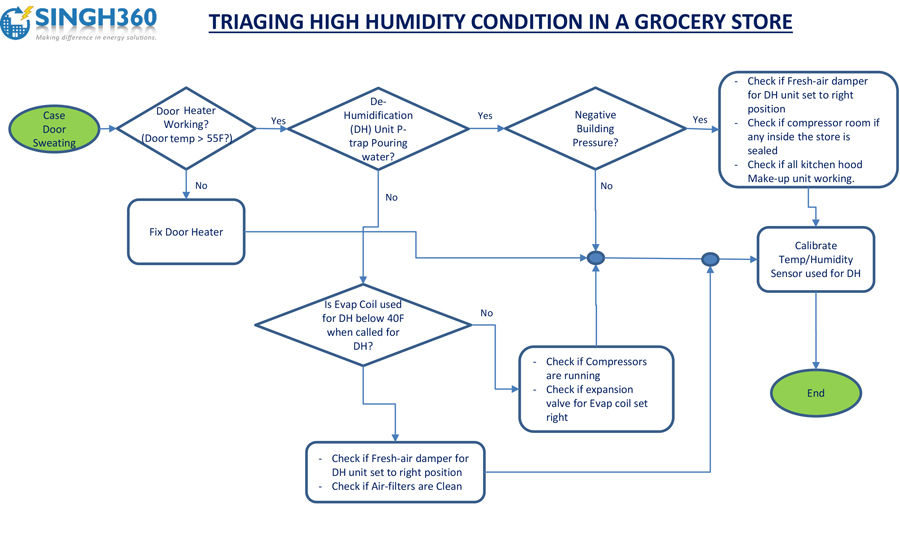

DIAGNOSING HUMIDITY PROBLEMS

According to Singh, there are four basic steps to diagnosing humidity problems in supermarkets.

No. 1: Check the doors on the refrigerated cases — How many doors are sweating? If only a few are sweating, then fix the door heaters. Lowering the HVAC setting can consume 30-40 kW versus fixing 100-W heaters. If all the doors are sweating, check to ensure the anti-sweat condensate control is working and is properly set.

No. 2: Calibrate the temperature and humidity sensors — Calculate the dew point, and check if the doors that are sweating are above the dew point. Refrigerated cases are designed to have temperatures above 57° as well as 75° dry-bulb temperature and 55 percent relative humidity.

No. 3: Check the P-trap on the dehumidification unit — Is condensate flowing out of it? If the P-trap is dry, check evaporator coil temperatures of the DX unit. It should be below 45°. If it isn’t, fix the DX unit.

No. 4: Check the building pressure — Prop open an entry door ½ inch and feel the air direction. If the pressure is negative, check the fresh-air damper’s control of DHU, the make-up air unit dampers, and ensure the compressor room (if inside) is fully sealed.

SUMMARY

In addition to being essential to customer comfort and energy efficiency, humidity control in a supermarket is also an important component of a properly functioning refrigeration system. Open cases in a humid environment have to work harder to maintain safe food temperatures while also working to dehumidify the ambient air. That is not good from a refrigeration system efficiency or equipment life standpoint.

- Here are some tips to help ensure proper humidity levels:

- Control humidity and door heaters using dew point. Optimum settings are about 74° dry bulb temperature and 53° dew point;

- Ensure the DHUs are functioning as designed;

- Ensure door heaters are operational;

- Maintain a positive building pressure;

- Seal the compressor room if it’s inside the building;

- Ensure all makeup air units are operating and bringing in the correct cfm; and

- Properly deploy reheat.

Publication date: 10/2/2017

Report Abusive Comment