Refrigeration contractors are keenly aware of the value of the maintenance they perform for their grocery store and supermarket clients, but, in some cases, they may find themselves working with clients who underestimate it.

These store owners are mired in what Ken Welter, senior manager of engineering at Baltic Trail Engineering, calls a problem-driven maintenance culture and could benefit from being educated on how to make their maintenance programs a positive contributor to their bottom lines rather than an expense.

“Maintenance isn’t a mystery,” Welter said during a speaking engagement at the recent FMI Energy & Store Design conference. “There are strategies that have proven to be effective in not only maintaining the equipment, but also in driving profits to the bottom line for the store.”

THE SPECTRUM OF CONTROL

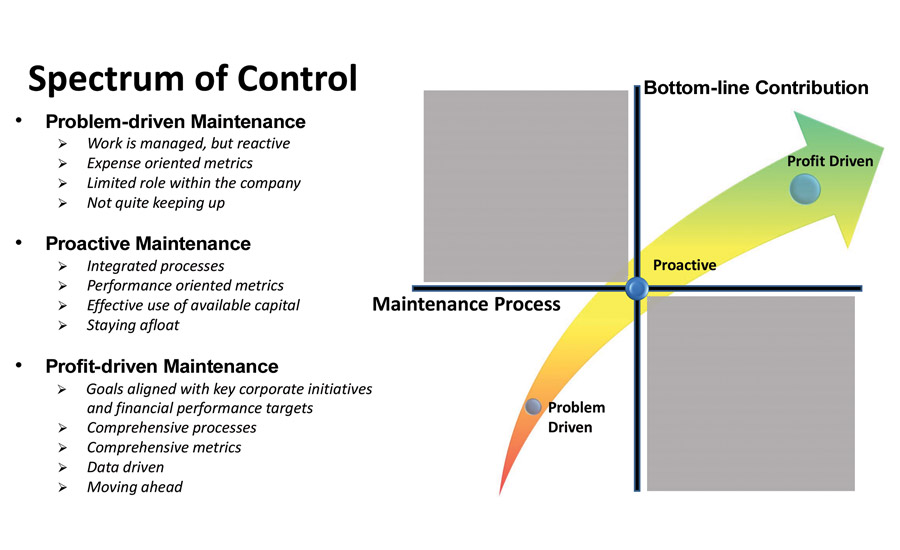

In order to help their supermarket refrigeration customers understand and appreciate the value of investing in the maintenance of the critical infrastructure in their stores, maintenance providers must be willing to evolve along the spectrum of control from problem-driven maintenance to proactive maintenance and then, ultimately, to profit-driven maintenance, said Welter.

As seen in Figure 1 (Page 30), the lower-left quadrant represents a traditional maintenance model. It represents how many maintenance organizations operate: They’re geared toward addressing problems as they develop and fixing things that break.

“Problem-driven maintenance is defined as work that’s reactive rather than proactive,” Welter said. “The metrics of a problem-driven organization are going to be oriented toward the expense of providing that service rather than looking at the opportunities to provide a return. These organizations have a limited role, and they have problems keeping up; they end up a little bit farther behind each year.”

Moving up the spectrum, in addition to handling the work that happens on a reactive basis, a proactive maintenance department has a bigger-picture view. These organizations look at key corporate objectives, such as energy performance, and employ metrics that allow them to track how stores are doing. They then act to improve upon that performance.

“A good proactive maintenance department does more than just address problems on a daily basis,” Welter said. “It’s able to address the problems that are sapping a company’s profits and prevent the slow decay that comes from a failure to reinvest in a store.”

The top of the curve is represented by profit-driven maintenance organizations.

“A profit-driven maintenance organization is a true competitive advantage for a company,” Welter said. “It has the data, the tools, and the analytics that allow it to maximize its value and effectiveness in achieving corporate strategic initiatives. It works in partnership with corporate leadership to provide the best operating environment for the store and the best shopping environment for its customers.”

The objective is to move your maintenance organization — and your customers’ stores — up the curve. There are four key steps in this process, said Welter: defining goals, identifying the metrics by which you will measure and define your success, identifying and securing the necessary resources, and executing the strategy.

DEFINING THE GOALS

Identifying goals should be the easy part, said Welter. If the supermarket company has clearly defined goals, you should be able to see how your maintenance fits into that. Your goals — both short- and long-term — should be aligned with the key financial and strategic goals of the company. They could include reducing lost sales caused by perishable shrink during fixture downtime or reducing energy and operating costs.

“The biggest part of the maintenance budget is always going to represent a direct expense to the store, and the store’s operating expenses probably get the closest scrutiny of any part of the budget,” Welter said. “Take a fresh and hard look to see if you can find ways to improve your services without increasing costs.”

As an example of how a profit-driven approach can save money for both the store owner and service contractor, Welter cited Baltic Trail’s process for prioritizing the store visits conducted by its field managers.

Any vendor management program requires regular audits of vendor performance, but, especially in a large supermarket company with hundreds of stores, it can be easy for some problematic stores to fly under the radar.

“Data on many store performance indicators flow through our company every day,” Welter said. “Extracting some of the key indicators — service call count, out-of-contract service cost, refrigerant usage, and time since last field manager visit — and prioritizing those indicators by relative importance allows us to rank the stores by those indicators. We use this simple ranking to prioritize store visits for our field managers.”

With this ranking updated weekly, field managers are required to visit the top five stores in their portfolios within the week, complete a detailed inspection, and create a follow-up vendor work list.

“We’ve found that this simple program has been one of the reasons we’ve been able to achieve a trend of reduced out-of-contract cost and improved store performance,” Welter said. “Over time, this also reduces our service vendor’s costs by reducing their emergency service and other in-contract service calls.”

In addition, Welter noted a supermarket company of any size is going to dedicate a fair amount of resources to sustainability initiatives and meeting regulatory compliance goals. The maintenance department can and should take the lead in these areas. Show the chief financial officer (CFO) your plans to target the biggest energy offenders, drive down refrigerant leaks, target failed infrastructure that may be causing food safety issues, and reduce slips and falls in the stores, said Welter, as all of these have clear financial implications.

“Look at these through the lens of profit-driven maintenance to help you provide a financial benefit to the store far in excess of the investment the company is making,” Welter said.

“Once the strategic goals are in place, define the tactical goals that will get you there. Start by making a full assessment of your maintenance organization and your processes. Give your service personnel clear guidelines and the power to act. And, if you don’t have a process manual, create one.

“The maintenance department is responsible for many different functions in taking care of a store, and if those processes are not well defined, you’ll have a hard time controlling them,” he continued. “In addition, putting the processes down on paper will help you identify ways in which you can improve upon them.”

IDENTIFY THE METRICS

Traditional metrics include keeping track of total maintenance time spent inside the stores, service calls at the stores, and how often you’re going there on emergency calls. Beyond those traditional expense metrics, look at the metrics of your maintenance that are actually impacting store profits, such as energy performance, refrigerant management, fixture downtime, and perishable shrink.

“A central element of profit-driven maintenance is that it is data-driven,” Welter said. “When examining the data, look at money spent and both current and historic results. When you look at data over a number of years, you’ll see the areas where it’s trending downhill and where you need to refocus your efforts to maximize your value to the stores.”

DETERMINE THE RESOURCES

It’s not so much about the amount of resources that you have, it’s directing those resources to have the greatest possible impact.

“Every operation is resource-constrained,” Welter said. “Having fewer resources doesn’t necessarily prevent you from reaching your goals. It might lengthen the timelines, but it doesn’t keep you from getting there.”

If you use your resources to good effect, you’ll be able to show your value and provide the company with a financial return on maintenance that rivals any other investment it might make, said Welter. Do that and you’ll find that you have partners and allies in store operations and in the finance department, and requests for additional resources or new projects will fall upon more receptive ears.

“There are always going to be the urgent tasks that must be completed, but a problem-driven organization is going to be doing those at the expense of the important big-picture needs,” Welter said. “A profit-driven maintenance organization is going to be taking care of urgent needs as well as the big-picture needs. It’s important not to lose sight of the things that move the company forward.”

EXECUTE THE STRATEGY

Having evaluated the data, you’ve identified the best opportunities to provide a financial return that proves the value of your program. Now, Welter said, it’s time to create some wins. Undertake — and highlight to the store’s management — projects that address the store’s current and long-term goals, such as reduced store expenses, perishable shrink, energy use, and refrigerant leakage.

Demonstrate and document the return to set the stage for the next capital investment opportunities. Keep the CFO in your corner. For capital projects, develop a good reporting format to capture your spend against budget.

Welter concluded that there is a path and a process to move a maintenance organization from one that is problem-driven to one that is profit-driven.

“Think about where your maintenance organization resides and know that traditional maintenance isn’t the future,” he said. “Simply helping a store avoid a downhill slide does not contribute to the growth of the company.”

Publication date: 1/11/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment