In this Service Ticket situation, a repair was accomplished on a 3.5-ton, 14-SEER, R-22 split system at the beginning of the cooling season, and the technician’s description of the problem was that a leak was found in the suction line. Six weeks have gone by since the previous service company was there. When you arrive, you find the house to be uncomfortable, and the following conditions:

In this Service Ticket situation, a repair was accomplished on a 3.5-ton, 14-SEER, R-22 split system at the beginning of the cooling season, and the technician’s description of the problem was that a leak was found in the suction line. Six weeks have gone by since the previous service company was there. When you arrive, you find the house to be uncomfortable, and the following conditions:

• The indoor fan motor is operating, and airflow volume through the building is normal; and

• The compressor and condenser fan motor are operating, but the suction line is colder than it should be, and the liquid line, on which there is no filter drier, is very hot.

Before you can proceed with a more detailed evaluation of the system, it shuts down. After a delay, a restart occurs, and you are able to determine that in the 95?F ambient temperature, the discharge pressure goes up well over 300 psig before the system shuts down again.

Your troubleshooting question: What is the underlying problem with this system, and what do you need to do in order to get it operating properly?

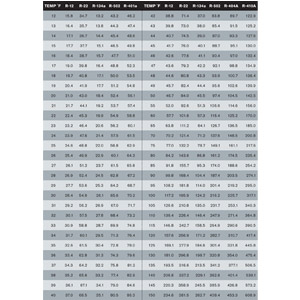

Here’s a hint: Refer to the temperature/pressure chart (click to enlarge).

SIDEBAR: SOLVING THE SERVICE TICKET

In the Dec., 15, 2014, issue of The NEWS, I asked readers to solve a question regarding “Not Enough Heat.”

The Question: A technician responds to a call of not enough heat. A measurement on the system, which was installed in 2013, confirms the discharge air temperature is significantly lower than normal. The volume of airflow is correct, and the filter, replaced at the beginning of the season, is clean. An ammeter check shows the proper current draw for the two elements connected by the red wiring to their sequencer. A check on the two elements connected by the yellow wiring to their sequencer shows a current draw of 0 A. The next troubleshooting step shows: 240 vac across connections M1 and M2 of the sequencer, 240 vac across connections M3 and M4 of the sequencer, and 24 vac at H1 and H2 of the sequencer.

1. What did your check of the M1/M2 and M3/M4 connections tell you about the condition of the elements, the limit switches, and fusible links wired in series with the elements?

2. What is the next step to take in servicing this equipment? For a link to the schematic, visit http://bit.ly/ServiceTicketSchematic.

The Answer: “Our meter tests showed the elements, fuses, and limit switches are all OK. The sequencer needs to be replaced.” Congratulations to Don DeCarr of Utica, New York, whose response was drawn among those who responded correctly. DeCarr will receive a Fieldpiece LT-17A digital multimeter.

If you have the answer to this issue’s question, submit it via email to thenewstroubleshooting@techtrainassoc.com. Submissions can be sent via regular mail to Technical Training Associates, PO Box 2259, Green Valley, AZ 85622. All correct answers will be entered into a drawing for Jim’s DVD, “Schematic Symbol Fundamentals and Translating What They Mean”.

Publication date: 6/22/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment