|

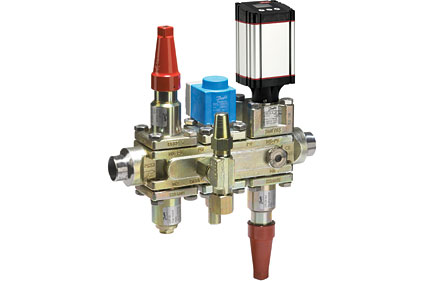

| A single valve body with multiple port openings was part of the equation for maintaining proper refrigeration control at an Arizona plant. |

No Sour Cream

Daisy Brands, a Garland, Texas-based sour cream manufacturer, recently opened a plant in Casa Grande, Ariz. The company utilized components from Danfoss’s Flexline™ family of motor control valves and control stations to maintain proper refrigeration control.

“Making sour cream requires close temperature control to maintain quality,” said Tom Cooper, president of Refrigeration Concepts Inc. of Comstock Park, Mich., which installed the equipment. The Arizona site consisted of an ammonia refrigeration system producing chilled water to vats, silos, and the supply evaporator coils in the storage area. Circulation of the refrigerant is controlled by valves assembled in valve trains, which open and close to regulate the flow from the compressors to the heat exchangers, evaporator coils, and condensers, stated a report from Danfoss.

Rather than using conventional valve trains that could have required up to 250 welds on-site, the end user chose Flexline, a platform that consists of an ICF station of a single valve body with multiple port openings. Individual valves can be specified and installed at the factory to build the required configurations.

Cooper said the installation took about 45 minutes, with two welds implemented on each valve train. “These are weld-in line trains,” Cooper said. “This eliminates the need for flanges and gaskets.”

Quick Serve

A couple of quick-serve restaurants in Wisconsin are benefitting from an evaporator efficiency controller from KE2 Therm Solutions Inc. of Washington, Mo.

At the Cudahy, Wis. location, the ice buildup looked like Antarctica, said an assistant manager. With the installation of the K2 Evaporator Efficiency controller, defrost cycles were reduced by nearly 75 percent, claimed the manufacturer. Defrosting went from 22 times in five days using a time clock to 16 times in five days, while the freezer was being cleared of ice. Once the ice was cleared, the defrost frequency was dropped and stabilized at six defrosts in a five-day period.

The defrost improvements were also made for a similar situation at a site in West Allis, Wis. According to Andy Fincutter, service technician, A to Z Refrigeration, Burlington, Wis., the West Allis location’s controllers’ remote monitoring capabilities included a MasterView page that displayed critical system readings and set points. “I can see more information on one page and know what is going on in the system in a matter of seconds,” said Fincutter, whose company installed the controller. “It would take me 20 minutes inside the box to get the same information without this equipment.”

Refrigerants: CO2

The use of CO2 as a refrigerant for refrigeration systems in supermarkets is well documented. A recent report issued by Carel Industries S.p.A. examined a supermarket in Turkey whose medium- and low-temperature units are served by a transcritical CO2 booster compressor rack.

The significance of this project is that it is being used in a high-ambient temperature climate, whereas transcritical CO2 was originally thought to be able to work efficiently in areas where average annual temperatures did not exceed 60˚F. Yet, according to Carel, the systems in Istanbul can operate when ambient temperature exceeds 90˚. An entire compressor rack is maintained by one controller that can manage the low- and medium-temperature compressors and the transcritical section simultaneously.

The medium-temperature line consists of four compressors, the first featuring modulating operation controlled by an inverter. The gas cooler is fitted with an evaporative cooling system to cool the inlet air. The high-pressure valve optimizes gas cooler pressure. Receiver pressure is controlled by two regulating pressure valves in parallel terms. A plate head exchanger serves the dual purpose of subcooling the liquid delivered to the units and heating the gas expanded by the same units.

The low-temperature line uses one inverter-driven compressor, with the discharge gas joining the gas coming from the medium-temperature line and the flash valves. This happens after having been cooled by an intercooler stage.

Refrigerants: HFCs

The pending 2020 phaseout of HCFC-22 is causing some owners with still well-operating systems to consider retrofit options.

One refrigerant, HFC-427A, manufactured by Arkema, has been favorably utilized in both air conditioning and refrigeration applications. R-427A was recently used to retrofit the air conditioning unit for Solar Supply Inc.’s warehouse office in Lake Charles, La. Solar Supply is a wholesale HVACR supply company with 57 sales offices in Alabama, Arkansas, Louisiana, Mississippi, and Texas.

Paul Brame, local branch manager for Solar Supply, was interested in learning more about R-22 retrofits and relating his firsthand experience with these products to his customers. He noted the similarity of R-427A to R-22 in air conditioning applications as Brent Miller’s Heating and A/C, Iowa, La., performed a retrofit project, with Arkema’s technical service personnel on-site for support.

The retrofitted system consisted of a 3.5-ton heat pump, utilizing an orifice as the expansion device. The air handler was connected to the rooftop-mounted condensing unit via a 10-foot vertical riser.

Initial readings were taken in the morning to verify system performance with R-22 before the original refrigerant charge was recovered. The filter drier and Schrader valve caps and cores were replaced per standard maintenance procedures. A deep vacuum was drawn on the system before recharging with R-427A. Charge weight of the new refrigerant was optimized and readings were taken to compare to R-22’s system performances, which were found favorable.

Publication date: 10/7/2013

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment