The actual impact of the Environmental Protection Agency's changes in Section 608 of the act, which are scheduled to become effective March 14, 2005, will not be known for some time. What is clear is the agency is making a significant attempt to address the growing number of new refrigerants that are entering the marketplace.

The EPA has made clarifications and reduced loopholes that have existed for more than a decade in the leak repair requirements of the regulations. The statute is much more specific in terms of enforcement and documenting the details of an event.

More than ever before, refrigerant record keeping that starts and ends with, "found leak, fixed same," won't be enough anymore. Neither will simply adding refrigerant to a system without calculating a leak rate and diligent efforts to locate and repair refrigerant leaks.

The rule changes affect all sectors that use refrigerants for comfort cooling, commercial refrigeration, industrial process refrigeration, or federally owned systems. It also affects appliances within each of these categories that contain CFC or HCFC refrigerant charges over 50 pounds and HFCs that have ozone-depleting components.

Included in the changes is a clause requiring HCFC blends, such has R-401A, to meet the same regulatory and recording requirements as CFCs. The amendment also adopts into regulation the leak rate calculation and requires that the leak rate be calculated each time refrigerant is added to an appliance.

Most of the changes deal with confirmation and clarification of existing requirements. However, within the amendment, there is a new provision that gives users the option of changing their leak rate calculation method.

More Changes Possible

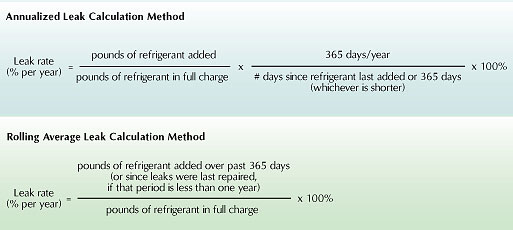

For 13 years, equipment owners and operators have been required to "calculate leak rates" with no regulatory method. Most owner operators chose the "annualized" leak rate calculation method discussed in the EPA and Chemical Manufacturers' Association (CMA) guide,Compliance Guidance for Industrial Process Refrigeration Leak Repair Regulations Under Section 608 of the Clean Air Act.The guide mentions two methods for calculating leak rates. The "annualized" option detailed in the guide showed the calculation method. The second option, the "rolling average," was listed as an option, but no formula was given. That is, until now.

The EPA's announcement of the changes in the Jan. 11, 2005, issue of the Federal Register said the agency believes the annualized method has the advantage of being familiar, while the rolling average catches certain leaks more quickly. The agency said its preferred approach at this point is to provide appliance owners and operators greater flexibility in calculating leak rates, rather than mandating the exclusive use of one method. "However, EPA is not opposed to considering additional methodologies for calculating or defining the leak rate, and may propose alternative methodologies in future rulemakings," said the announcement.

Of course, the impact of the rolling average method is something that owners and operators in every sector will have to determine before deciding whether to switch to the new formula. Other factors to be considered include the size of the cooling system and amount of refrigerant it contains.

Refrigerant Management

Switching formulas will also depend on how a facility is operated. For example, a larger business or organization that closely monitors its equipment may be more inclined to switch to the rolling average than the small grocery store that learns its unit has a problem when the ice cream starts to melt.Owners or operators of refrigerant equipment who switch to the rolling average method must make sure the change coincides with the date of the rule change. Also, once chosen, the calculation method must be used consistently for the lifetime of all applicable equipment at an operating facility.

Determinations about the benefits of either method are going to have to be made on a case-by-case, facility-by-facility, basis. Owners/operators will need to make sure they have the necessary infrastructure in place to deal with the changes and the resulting documentation. They will need to have the capacity to promptly calculate leak rates and fix the problem within the allowable time frame.

Regardless of which method a facility or organization chooses to use, the fact remains that you need to have a refrigerant management system that starts with a clearly defined chain of command starting with upper management, the ultimate responsible party in the eyes of the law. The system would also include clear policies and work instructions, methods for consistent documentation, records routing and retention processes, and reporting capabilities.

It stands to reason that with new rules will come new enforcement, such as more frequent un-announced inspections of facilities, demands for records, and more whistleblowers seeking a piece of the action.

The rule changes are a wake-up call to facility owners and managers to initiate programs at their facilities, or to re-establish programs that have fallen by the wayside for reasons including downsizing and consolidation. They can either heed the wake-up call, or prepare for a rude awakening.

Mark Harbin is Refrigerant Software and Compliance Services manager at ESS, a provider of integrated software and services such as EH&S and Crisis Management. ESS' Essential Suiteâ„¢ and Compliance Suiteâ„¢ have helped more than 35,000 businesses, government agencies, and other organizations comply with international, federal, state, and local regulations, as well as industry standards. For more information, go to www.ess-home.com; or for compliance services, visit www.ess-home.com/content/services/default.asp.

Publication date: 03/14/2005

Report Abusive Comment