BOILER FEED UNITS

When you install a boiler feed unit, all the returns must drain into this receiver. The only way water can now enter the boiler is by turning the feed pump on with a pump controller located on the boiler. This receiver is vented to the atmosphere because it can't withstand any pressure, so all those former wet returns now have no back pressure from the boiler to offset the pressure from the supply side.Now the steam can reach down into those former wet returns and shove all that water back and forth in the piping, eventually showing up at the vent pipe, filling the boiler room with steam. Of course, the water hammer is incredible.

F&T TRAPS

The answer to this problem is to install F&T (float and thermostatic) traps at the base of each riser drip and at the end of each main as well as radiator traps on each radiator. These traps will prevent the steam from entering into the return lines and pouring out of the receiver's vent line.Unfortunately, sometimes it isn't economically feasible or even possible to install all those traps, and installing one "master" F&T trap at the inlet to the receiver may not prevent the steam from showing up at the vent pipe. And it does nothing to prevent the steam from still reaching all the way down into those former wet returns, creating water hammer and other problems. Remember, the returns are now isolated from the boiler's back pressure because they all drain into the vented receiver.

THE FALSE WATER LINE

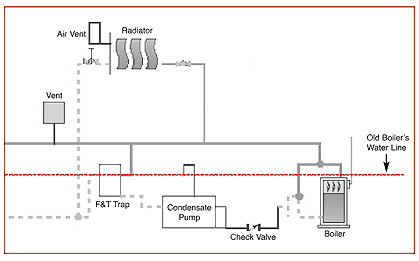

There is a way of getting the new installation to work: create a "false water line." This technique allows you to keep the old wet returns pressurized and full of water the way they were in the original system.One method to accomplish this is to use a 2-inch F&T trap and hang it right near the boiler feed unit. Mount the trap so that its location closely mimics the old boiler's water line. The trap should have two inlet and two outlet tappings. Combine all the wet returns from the system into one common line, and pipe this line into one of the trap's inlet connections. Then run a steam line from the steam main over to the other inlet connection of the F&T trap. This equalizing line puts pressure on the backside of the wet returns, keeping them wet and pressurized, and the pressure balances off the steam pressure from the supply side.

Now, pipe a line from one of the trap's outlet connections to the feed tank's inlet connection. As the condensate forms in the system, the F&T trap will open to drain this returning condensate back into the receiver. It is important that the new water line be high enough to cover everything that was originally covered by the old boiler's water line. It should not be too high since there is a chance the water could flow back into the main, causing water hammer and damage to the system's main vents.

Reprinted with permission from the McDonnell & Miller/Hoffman Specialty newsletter CounterPoint, volume 12, issue 2, October 2005. For more answers to steam or hot water heating questions, visit the McDonnell & Miller and Hoffman Specialty Web sites at www.mcdonnellmiller.com and www.hoffmanspecialty.com.

Publication date: 01/09/2006

Report Abusive Comment