At the AHR Expo this year, Daikin Applied introduced SiteLine Building Controls — a portfolio of scalable, cloud-based technologies to connect, monitor, and manage both individual pieces of HVAC equipment and integrated building systems. Visitors to the booth were also able to explore the inner workings of the company’s Magnitude magnetic-bearing centrifugal chiller through an immersive virtual-reality experience.

“Daikin has been a proud AHR Expo exhibitor and attendee for decades,” said Jeff Drees, executive vice president at Daikin Applied. “We were thrilled to see many familiar and new faces in-person this year. Having a booth allowed Daikin to share our industry expertise with attendees, showcase new products, and build and enhance relationships with customers and colleagues in the industry.”

New Controls

Daikin Applied’s recently introduced SiteLine Building Controls gives building owners and operators the tools and insights needed to optimize performance, improve IAQ, and trim energy use and carbon emissions. The portfolio currently includes three offerings to meet a range of needs:

- SiteLine for Wireless BAS combines the power of wireless technology and the cloud to integrate light-commercial, applied, and VRV equipment into one, easy-to-manage BAS for both retrofits and new construction. Plus, the controls feature advanced security to protect user data and scalability to accommodate future expansion.

- SiteLine for Dedicated Equipment delivers 24/7 monitoring and control for standalone equipment, including rooftop units and chillers. A direct connection to hundreds of data points — from any connected device, anywhere in the world — provides precise insights for easier decision making. Preventive alerts also help reduce downtime and emergency service calls.

- SiteLine for Pre-Programmed BAS helps users enhance performance and efficiency throughout an entire facility with a BAS that links and optimizes Daikin equipment. This pre-engineered system offers configurable control without the need for custom programming. Local and cloud-based connectivity provides additional flexibility.

“SiteLine is designed to provide effortless insights,” said Drees. “Most controls require a significant amount of knowledge, configuration, and programming. And for building retrofits, unforeseen installation challenges cost both time and money. The hardware and software that comprise the SiteLine portfolio, however, offer out-of-the-box functionality for easy setup, eliminating the need for onsite programming, which often requires a specialized engineer or technician.”

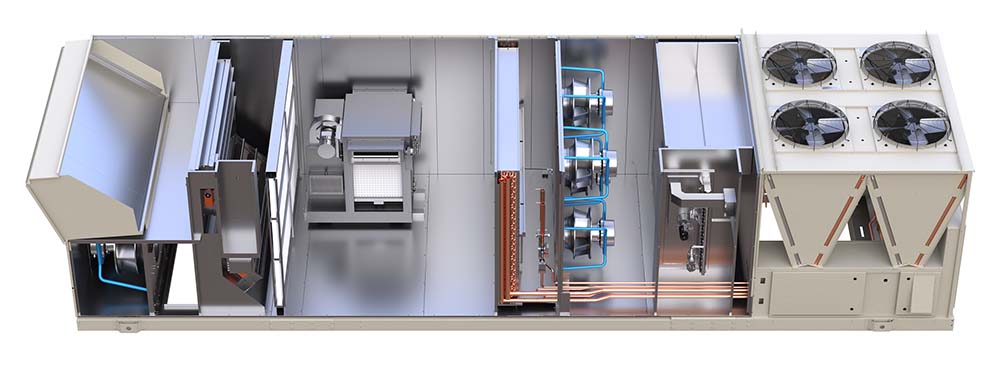

REBEL UPGRADE: The upgraded Rebel Applied with enVerid Sorbent Ventilation Technology (SVT) combines the benefits of sorbent media with a configurable rooftop unit. (Courtesy of Daikin Applied)

The technology solves the integration issues commonly associated with HVAC equipment and is contractor-friendly as a result. Plus, it keeps facility personnel connected to their operations at all times, and provides complete transparency into the entire HVAC ecosystem to create comfortable and sustainable environments where people work and live. Intuitive dashboards keep facility personnel connected to their operations at all times, arming them with data to drive efficiency and lower costs while maintaining comfort.

Visitors to the booth were also able to experience a life-sized 3-D version of the all-new, low-pressure Magnitude magnetic-bearing centrifugal chiller, using next-generation refrigerant R-1233zd, as well as Daikin’s Innovation Roadshow trailer. Launched in 2003 and recently renovated, the decked-out trailer features the company’s latest innovations and allows attendees to take a deep dive into a range of technologies, from rooftop units and air handlers to applied terminal systems and water- and air-cooled chillers.

Main Themes

Some of the themes focused on in the booth included decarbonization, IAQ, and digitalization — all topics that are important, as they are reshaping customer needs and expectations, and the industry at large, said Drees.

IMPROVED IAQ: The SmartSource DOAS water source heat pump improves IAQ and ensures that proper ventilation is efficiently delivered to the desired space. (Courtesy of Daikin Applied)

As far as decarbonization is concerned, federal and state mandates, as well as corporate commitments, are accelerating the move to low-carbon energy sources and technologies. Drees said there will be constant and growing pressure to cut energy use and emissions, and high-efficiency buildings and HVAC equipment are a key means to that end.

IAQ concerns existed before COVID-19, but the pandemic has put them squarely in the spotlight and forever changed how HVAC systems are evaluated. HVAC is now expected to deliver more than a cozy environment, with a larger focus on the overall health of a building and its occupants, said Drees.

Finally, converting building systems from analog to digital has been a decades-long process; however, Drees noted, “We don’t just need hundreds of data points from a rooftop unit; we need information to help improve outcomes.” So the next step is digitalization: turning data into practical, actionable insights that will transform processes and boost performance.

INNOVATION TO GO: Mike Schwartz, CEO of Daikin Applied, stands in front of Daikin’s Innovation Roadshow trailer. (Staff photo)

Meeting these challenges will require a deep pool of talent, and finding people continues to be a challenge, said Mike Schwartz, CEO of Daikin Applied Americas.

“A big challenge is finding enough skilled labor — or even non-skilled labor that we can train. The demand is unbelievably strong,” he said. “Between supply chain issues and having enough people to fill jobs, scaling the businesses is a more difficult prospect than it has been in the past. Now that most of the government subsidies have run their course, we're beginning to see more people looking for good jobs. I think that was a deep motivator for some.”

As Schwartz noted, supply chain issues will still be a challenge this year, as the lack of microchips continues to be an issue. Although the outlook may be getting better.

“What we're hearing from suppliers is that the chip situation should be easing in the next 60 to 90 days, but it depends on the type of chip. Some are easier to find, while other chips are still hard to source,” he said. “With the steel situation, which was tight at the beginning, we're seeing signs of that loosening up and pricing getting back down to earth. Copper is still a volatile commodity, and the price is high. Going forward, we’re going to see things bounce around, but the good news is the market for us is just tremendously positive and strong.”

Schwartz noted that Daikin has a robust backlog, which is due to increased growth in the school market, data centers, and electric vehicle plants. As for commercial office space, the demand in that market continues to be weak for now.

“I think in the next year or so, we may see some transitional repurposing of these spaces into condos or multifamily housing or something else,” he said. “I am not sure that we'll ever see the return to the full office footprint that we’ve had in the past, but it’s not clear yet.”

Report Abusive Comment