“Several cities are moving to zero emissions for new construction,” said Jacob Ford, sales director for Samsung. He sees efficiency requirements, coupled with fossil fuel reductions, only improving the prospects for inverter-driven technology.

Other external factors were already smiling on this equipment sector before the pandemic boosted demand for home offices and improving “trouble spots” in a home. Electrification efforts and measures such as residential gas hookup restrictions have been nudging the market further toward the ductless (and ducted) solutions in more areas.

Now, ductless growth is moving beyond both the old sunroom/garage appeal and the continuing upgrade market, working toward a foothold in original residential HVAC design.

With so many factors contributing to a tailwind of residential demand, that makes proper deployment all the more important. Common errors in an expanded field would only affect that many more homes. What tendencies have manufacturers seen that can hinder performance as designed and sow the seeds for unwanted complaints?

Executive sales manager LG Air Conditioning Technologies

Sizing and Refrigerant Wrong Turns

“One of the most common or misunderstood practices is the lack of a torque wrench,” reported Ruben Marcucci, director of service for Fujitsu General America.

A good craftsman never blames his tools, as the saying goes, but having and knowing the right tool for the circumstance is also part of being good.

Fujitsu’s manuals and online training specify torque wrench use, said Marcucci, along with “the importance of the proper torque setting to prevent refrigerant leaks on flare connections.”

Terry Frisenda, LG Air Conditioning Technologies executive sales manager, and Heather Buchicchio, director of product marketing for Mitsubishi Electric Trane HVAC US, agreed independently on another common issue.

“Sizing matters!” said Frisenda. “There is a myth around oversizing inverters and expecting them to ‘slow down’ to meet the demand conditions. Inverters must still be properly sized the same way we properly size conventional systems.”

Buchicchio commented that “Even highly efficient heat pump systems with inverter-driven compressors need to be properly sized to the building’s load.” She emphasized that these systems do have both a maximum capacity and a minimum capacity, documented in manufacturer literature.

“You can reduce callbacks by accounting for the system’s capacity range and being diligent about load calculations,” she said.

Buchicchio advised contractors to “get comfortable reviewing load summary reports” and to take care to verify details like site location, U-values, and ventilation loads. A second set of eyes doesn’t hurt, either.

“The more people on your team who can spot errors and omissions, the better.”

Meanwhile, Jose De La Portilla, Samsung HVAC’s national training manager, came ready to list a trio of challenges.

“Condensate connection, refrigerant charge, and communication wiring,” he said. “Many installers take the normally closed float switch from a condensate pump or an overflow switch and use it to break either the high voltage power lines or the low voltage communication lines. When they do that, the system generates an error that can be difficult to trace.”

He noted that Samsung has a dedicated float switch connection, aiding diagnosis by generating a more specific error in that situation.

De La Portillo encouraged installers not to rely on traditional factors like operating pressures or superheat and subcooling when charging a mini split. They will not suffice given the complexity of the equipment involved, he said.

“Weighing the refrigerant charge will guarantee the system is charged appropriately and runs as it should,” he advised.

Finally, De La Portillo cautioned about a couple of common communication wiring issues.

“Some installers do not realize the communication wiring must be ran with a two-wire stranded shielded cable, or they don’t realize that when using shielded cable, the conductor should be grounded at the outdoor unit only,” he said.

His tip is to keep the communication wires a few inches away from the high voltage wires to prevent induced current around the communication wiring from creating a fault.

Support and System Supplements

The flip side of knowing what can go wrong is providing resources to maximize quality installations and happy customers.

MOVING MARKET SHARE: As decarbonization efforts and other factors favor inverter technology, mini splits may well gain more of a foothold in new construction. (Courtesy of Mitsubishi Electric Trane US)

“Our virtual content is improving daily,” LG’s Frisenda said, “giving contractors the option to attend training on their schedules and eliminating travel costs and lost time.”

At Samsung, the company has created quick installation guides that De La Portilla described as still showing installers “the exact steps and nuances of installing a mini split” without reading the entire manual. These guides highlight installation keys and refer to the main manual for additional information.

De La Portilla also pointed contractors to over 100 videos that Samsung has posted on its YouTube channel and its own mobile app. He added that examples of the app’s additional support include pressure temperature charts, warranty history check, and using the camera to register a system for extended warranty coverage.

Even when installed perfectly, a typical standard mini split system may not offer one particular feature increasingly in demand: outside air. In a time when increased outdoor air is penetrating public consciousness as a tactic for reducing COVID transmission, that can appear to be a rare downside of this equipment on its face.

However, as Frisenda noted, “several good third-party manufacturers” produce self-contained energy recovery ventilation units that can work alongside ducted or ductless mini split systems to meet residential fresh air needs.

Ford observed that not only are manufacturers offering several different filtration options as an alternative, but homeowners may be able to implement a decoupled fresh air system, which he recommended as generally the best choice.

Bells and Whistles

Market trends and installation tips have their part in the current ductless landscape, but the rest of the story leans on an industry constant: new features and steadily improving performance capabilities.

Progress at Fujitsu General is tied to the ongoing theme of connectivity within the smart home. Karim Yasin, senior director of product management, said that with the company already a primary actor in areas of big data, AI, IoT, and cybersecurity, “it was just natural” to bring that knowledge into the HVAC world.

Specifically, Yasin mentioned IFTTT (If This, Then That) app technology aiding the FGLAir app in connecting its HVAC systems to the user, as the system works to respond to the user’s location and preferences.

Samsung’s Ford chose to highlight WindFree™ technology designed to ventilate while avoiding any draft effect. He said this has been especially effective in bedroom applications. Asked about any controls highlights, he confirmed that Samsung is one of a group of manufacturers offering a 24V adapter that lets mini splits be controlled via traditional thermostats.

At LG, a Single Flex-A-Coil cased coil and communication kit is launching this spring, according to Frisenda. This is designed to let homeowners enjoy LG heat pump efficiencies while maintaining a third-party gas furnace.

“This will provide a dual fuel option for heat as well as high-efficiency cooling for retrofit applications,” he added.

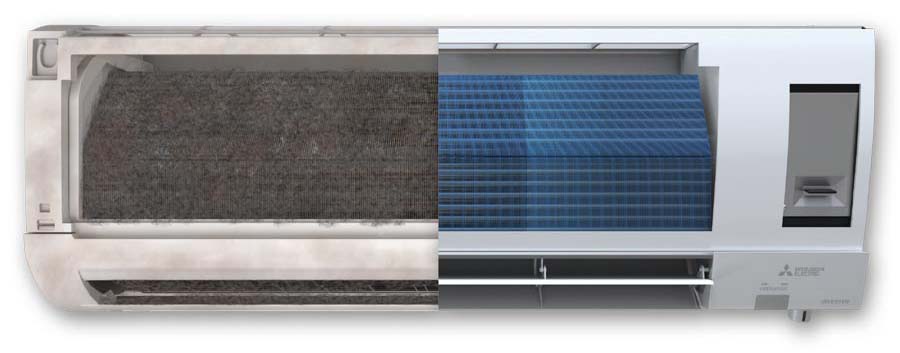

BRAND NEW COAT: This illustration depicts 10 years of build-up on an improperly-maintained unit versus a clean unit protected with METUS’ upcoming Dual Barrier Coating. (Courtesy of Mitsubishi Electric Trane US)

Mitsubishi Electric recently unveiled a patented Dual Barrier Coating (in the new deluxe wall-mounted H2i plus™ system), according to METUS’ Buchicchio. The coating serves to prevent dust and dirt accumulation, leaving a cleaner inner surface.

Digging into the science, she explained that blended fluorine particles prevent hydrophilic dirt penetration, and hydrophilic particles prevent hydrophobic dirt from getting into the air conditioner.

Thus, the cleaner heat exchanger and blower wheel can hold off gradual heat transfer losses that typically add up over time. Buchicchio stated that units with this coating have 30% better airflow and consume 18% less energy than a system without it.

Moving from inside components to birdseye view, Buchicchio brought the conversation back around to the continuing consumer embrace of these systems and how it is not too late to catch up on (or update) core competencies for inverter-related equipment.

“As homes become smarter and their owners savvier, the demand for HVAC contractors with expertise in these systems will only grow,” she said. “And those ahead of the curve will have a significant advantage over their peers.”

Report Abusive Comment