The U.S. Environmental Protection Agency’s (EPA’s) final rule updating the requirements of its Section 608 Refrigerant Management Program went into effect January 1. According to the EPA, the final rule is designed to strengthen the existing program by requiring a number of industry best practices.

The EPA estimates the annual emissions reductions from this rule will be approximately 7.3 million metric tons of carbon dioxide equivalent (MMTCO2eq) and 114 ozone-depletion weighted metric tons (ODP tons).

RULE SUMMARY

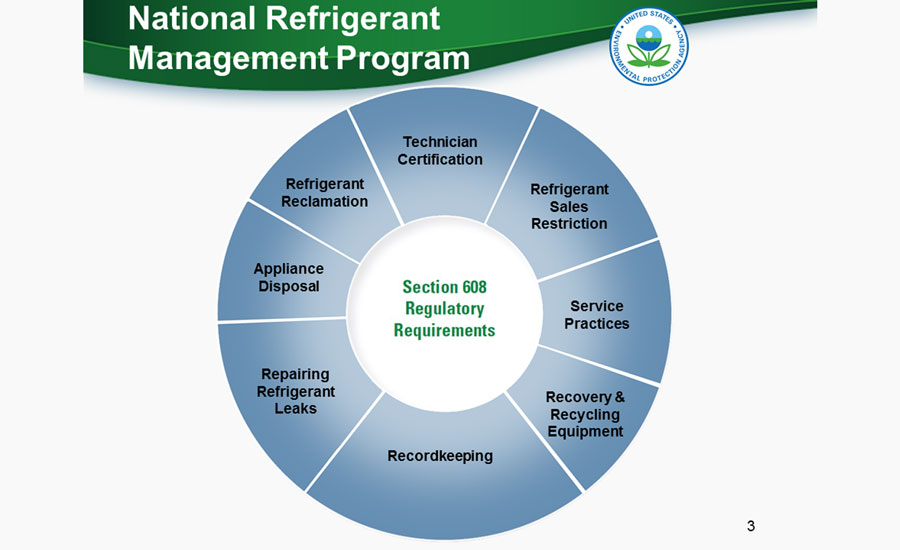

There are six major changes to the Section 608 requirements along with some additional requirements for technicians. The new rule:

1. Extends the requirements of the Refrigerant Management Program to cover substitute refrigerants, such as hydrofluorocarbons (HFCs). Basically, technicians must handle HFC refrigerants and appliances containing HFC refrigerants in the same manner that they’ve handled ozone-depleting refrigerants and appliances. The EPA exempted some substitutes from the Section 608 venting prohibition through previous rules, and those substitutes continue to be exempt from the requirements of this rule (see sidebar);

2. Lowers the leak rate thresholds that trigger the duty to repair refrigeration and air conditioning equipment containing 50 or more pounds of refrigerant. The new regulations lower the leak rates from 35 percent to 30 percent for industrial process refrigeration (IPR), from 35 percent to 20 percent for commercial refrigeration equipment, and from 15 percent to 10 percent for comfort cooling equipment;

3. Requires quarterly or annual leak inspections or continuous monitoring devices for refrigeration and air conditioning equipment that has exceeded the threshold leak rate;

4. Requires owners/operators to submit reports to the EPA if systems containing 50 or more pounds of refrigerant leak 125 percent or more of their full charge in one calendar year;

5. Extends the sales restriction to HFCs and other non-exempt substitutes, with the exception of small cans (containing 2 pounds or less) of non-exempt substitutes for motor vehicle air conditioner servicing; and

6. Requires technicians to keep a record of refrigerant recovered during system disposal from systems with a 5- to 50-pound charge size.

MORE DETAILS

The EPA is not changing the certifications or requiring recertification for currently certified technicians.

The new recordkeeping requirements for appliances containing 5-50 pounds of refrigerant go into effect Jan. 1, 2018. They require technicians who dispose of mid-sized appliances, such as residential split systems, to keep records of the location, date of recovery, and type of refrigerant recovered for each disposed appliance; the quantity and type of refrigerant recovered from disposed appliances in each calendar month; and the quantity and type of refrigerant transferred for reclamation or destruction, the person to whom it was transferred, and the date of the transfer.

New maintenance, servicing, repair, and disposal requirements also start Jan. 1, 2018. They require technicians, before opening or disposing of appliances, to evacuate ozone depleting substance (ODS) or substitute refrigerants to the evacuation levels specified in the regulations using certified recovery and/or recycling equipment.

The updated Section 608 regulations also include new leak inspection and verification test requirements for owners/operators starting Jan. 1, 2019.

Finally, the new rules impose updated sales restrictions for refrigerants. Starting Jan. 1, 2017, recovered ODS and substitute refrigerant may not be resold unless it has been reclaimed by a certified reclaimer or is charged into equipment belonging to the same owner. Starting Jan. 1, 2018, the sale of ODS and substitute refrigerant is restricted to certified technicians.

CHANGES ARE NOT DRAMATIC

The most significant change is that technicians must now handle HFC refrigerants and appliances containing HFC refrigerants in the same manner they’ve handled ozone-depleting refrigerants. And the other changes to the Section 608 rules will affect contractors and technicians in a number of ways.

Bruce Campbell, national account manager, United Refrigeration Inc., stressed the changes are not as dramatic as the term “final rule” makes them sound.

“Many of the changes are improvements to the existing regulation, which was passed in 1993,” Campbell said. “The original rule was written to restrict the sale and usage of Class I and II refrigerants [ODSs such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs)] to certified technicians.”

The key to the sales restrictions update is the inclusion of substitute refrigerants along with ODS.

“The word ‘substitute’ is the main difference between the old and new rule,” Campbell said. “Anyone seeking to purchase refrigerants after Jan. 1, 2018, will be required to show they are certified.”

The new rules may even contain business opportunities for contractors with their addition of leak inspection and verification tests for owners/operators

“Technicians will need to understand leak rates and help equipment owners calculate the leak rates of systems containing 50 or more pounds of refrigerant,” Campbell said. “It is up to owners/operators to provide technicians with the refrigerant charge for the system upon which the calculation can be made. Technicians will be able to offer refrigerant charge calculations as a new service.”

Once the charge has been calculated, the leak rate can be established. If the leak exceeds the allowable rate, technicians are required to report this to the owners/operators and schedule the repair. For commercial systems, a leak inspection must be performed according to a schedule set by the EPA. For systems with 50-500 pounds of refrigerant, the leak-inspection schedule states that systems must be checked once per calendar year until the owner/operator can demonstrate through the leak rate calculations that the leak rate has not exceeded 20 percent (commercial refrigeration) or 30 percent IPR for one year. For systems containing more than 500 pounds of refrigerant, the leak-inspection schedule is once every three months until owners/operators can demonstrate the leak rate has not exceeded 20 percent (commercial refrigeration) or 30 percent (IPR) for four quarters in a row through leak-rate calculations.

Another part of the rule requires verification tests of leak repairs. According to the EPA, initial and follow-up verification tests of leak repairs are required for appliances that exceed the applicable leak rate. The verification tests must demonstrate that leaks were successfully repaired.

In addition, an initial verification test must be performed before any additional refrigerant is added to the appliance, and a follow-up verification test must be performed after the appliance has returned to normal operating characteristics and conditions. There is no minimum timeframe. Technicians are required to provide service invoices and records of the results of leak inspections or verification tests to owners/operators.

“The new rule provides contractors and technicians with tools that can be used to create long-term business relationships,” Campbell said. “By identifying leaks and leak rates, technicians can offer real cost-saving solutions to their customers.”

GOOD NEWS FOR GOOD CONTRACTORS

There’s good news for exceptional contractors regarding the final rule: If you’re already doing the right things when it comes to handling refrigerants, the latest Section 608 changes won’t be huge for you.

That’s the word from Barton James, senior vice president of government relations, the ACCA. The real issue, James said, is making sure the EPA enforces the rules to ensure that good contractors are rewarded and bad ones are identified and pressured to improve.

“A huge problem we have with refrigerant regulations as a whole is that there’s almost zero enforcement,” James told The NEWS. “The contractors who are doing the right things and re-investing in training their technicians and reclaiming refrigerant are always competing with the guys who aren’t. The good contractors are cleaning up after the bad ones every day, and that has been a frustration of ACCA’s over the years. But, when we talk to the enforcement division of the EPA about it, unless it’s a high-profile or financially significant case, they have no appetite to go after it.”

James noted that refrigerant regulations have simply become a fact of life and urged contractors to not only remain aware of the latest changes but to always be ready for more.

“There are a lot of changes coming, and we don’t have all the answers yet, especially when it comes to regulating flammable refrigerants,” he said.

LACK OF ENFORCEMENT

Joseph Kokinda, president and CEO of Professional HVACR Services Inc., Avon Lake, Ohio, echoed James’ sentiments.

“EPA 608 regulations are rarely enforced due to lack of oversight and personnel employed by the regulators,” he said. “I really can’t believe that adding more recordkeeping relative to ‘retired appliances’ is going to lead to better tracking and documentation of refrigerants.”

Kokinda said he believes building owners should be responsible for keeping leak-inspection and leak-rate documents from their contractors or their own in-house maintenance staffs. However, he does not believe it should be the responsibility of contractors to educate their customers in the new leak-check and recordkeeping requirements — with the exception being customers who see the value in such an education and those who are willing to compensate their contractors for providing it.

Regarding the new EPA rules’ lack of a retesting requirement for technicians who are already certified, Kokinda voiced his skepticism about how well such a requirement would serve its intended purpose anyway.

“Costs involved for updating one’s certifications are out of control and are a major deterrent to those who become certified and then stop there,” he said. “Learning and updating one’s ability still comes from within, not from regulations that demand it be done.”

AN IMPROVED FOCUS

At Johnson Controls Inc., William McQuade, executive director, global energy and sustainability policy, said proper leak-detection, handling, reclaiming, and recycling procedures are important for all refrigerants to maintain optimal equipment efficiency and limit the direct effect of the individual refrigerant’s ozone depletion and global warming potential (GWP).

“Johnson Controls applauds the U.S. EPA in the recent 608 final rule that adds HFC refrigerants to the existing required refrigerant management practices for CFC and HCFC refrigerants,” McQuade said. “Johnson Controls has been encouraging the addition of HFC refrigerants to the existing EPA rules for more than a decade. The 608 final rule is now consistent with the existing internal service practices Johnson Controls uses to handle all refrigerants.”

McQuade, who is also vice chairman of the Alliance for Responsible Atmospheric Policy (ARAP), noted that as a member of ARAP, Johnson Controls was a participant in the petition to the EPA that ultimately led to this rule. He added that the final rule’s lower allowable leak-rate thresholds and requirements for better documentation of equipment leaks will help limit direct emissions of refrigerants, provide better data on the leak rates of various types of equipment, and improve the focus on leak reduction in the unitary and commercial refrigeration sectors.

WHICH REFRIGERANTS ARE EXEMPT?

As part of the EPA’s Section 608 final rule, technicians must handle hydrofluorocarbon (HFC) refrigerants in the same manner that they’ve handled ozone-depleting refrigerants. However, the EPA had exempted some substitutes from the Section 608 venting prohibition through previous rules and those substitutes continue to be exempt from the requirements of the final rule.

Exempt substitutes are appliance/application specific. They include:

● Carbon dioxide, nitrogen, and water in any application;

● Ammonia in commercial refrigeration, industrial process refrigeration (IPR), or absorption units;

● Chlorine in IPR processing of chlorine and chlorine compounds;

● Hydrocarbons (HCs) in IPR processing of hydrocarbons;

● Ethane (R–170) in very low-temperature refrigeration equipment and non-mechanical heat transfer;

● Propane (R–290) in retail food refrigerators and freezers (stand-alone units only); household refrigerators, freezers, and combination refrigerators and freezers; vending machines; self-contained room air conditioners for residential and light commercial air conditioning; heat pumps; self-contained commercial ice machines; very low-temperature refrigeration equipment; and water coolers; and

● Isobutane (R–600a) and R-441A in retail food refrigerators and freezers (stand-alone units only); household refrigerators, freezers, and combination refrigerators and freezers; and vending machines. R-441A is also exempt in self-contained room air conditioners for residential and light commercial air conditioners and heat pumps.

Publication date: 2/6/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment