In a December 2014 Plumbing & Mechanical Hydronics Workshop column, we discussed the benefits of dual-fuel systems that combine a geothermal water-to-water heat pump with a mod/con boiler. The boiler can be configured to provide supplemental heat when the heat pump can’t quite keep up with the load. This allows the heat pump to be sized for 50 percent to 75 percent of design load while still providing the majority of the total seasonal heating energy requirement. In mission-critical applications, the boiler could be sized to provide full design load output if the heat pump was not operating. The latter also is helpful if you need to supply high domestic hot water (DHW) loads.

In areas where natural gas is not available, the mod/con boiler in a dual-fuel system will likely be supplied by propane. The cost of a heat produced by burning propane in that boiler may be significantly higher than that of heat delivered by the geothermal heat pump. For example, as of mid-December 2014, the price of propane in the Albany, New York, area was about $3.21 per gallon. If this propane fueled a mod/con boiler with an average thermal efficiency of 92 percent, the heat produced would have a unit cost of $38.03 per MMBtu (1 MMBtu =1,000,000 Btu).

The cost of electricity at the same location and time was about 16.3 cents per kWh. If this electrical energy operated a geothermal heat pump with an average seasonal coefficient of performance (COP) of 3.2, the unit cost of the delivered heat would be about $14.92 per MMBtu, less than half that of propane under the stated conditions.

In situations like this, it makes sense to prioritize the use of the lower-cost energy wherever possible. Reserve the more expensive energy to “top off” the load only when necessary.

AIM LOW

Designers also need to consider the COP of a geothermal heat pump is very dependent on the water temperature supplied to its condenser. The lower this inlet water temperature, the higher the heat pump’s COP.

In most residential systems, the overall load consists of space heating and domestic water heating. The latter load starts at relatively low temperatures. For example, where I live, in upstate New York, the annual average ground water temperature is about 50°F. It takes just as many Btu to raise a gallon of water from 50° to 60° as it does to raise that gallon from 110° to 120°. However, a heat pump is going to supply those low-temperature Btu at a much higher COP and, thus, at a lower cost per MMBtu.

If your intent is to maximize heat pump performance, domestic water preheating is an opportunity you don’t want to overlook.

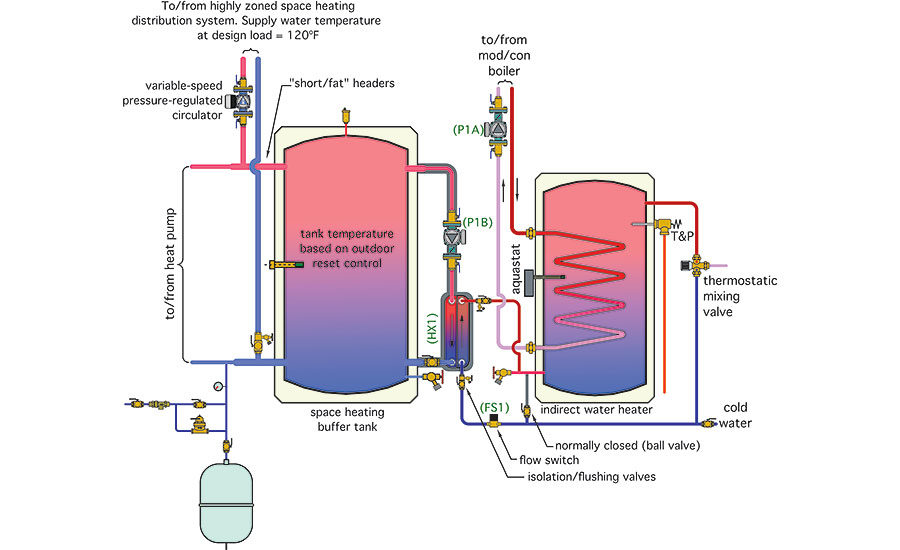

The partial system schematic shown in Figure 1 is configured to supply domestic water preheating, as well as space heating, to a low-temperature/highly zoned distribution system.

At design load conditions, the water temperature supplied to the distribution system from the buffer tank is 120°. This supply water temperature can be lowered as the outdoor temperature increases. At half load, the supply water temperature only needs to be about 95°. This keeps the heat pump — as well as the mod/con boiler if it’s needed — operating at the highest possible efficiency.

This configuration also maximizes the use of the heat pump for domestic water preheating. Whenever there is a hot water fixture demand of 0.8 gallon per minute or higher, the flow switch marked (FS1) closes its contacts. This turns on circulator (P1B) via a relay. The hottest water at the top of the buffer tank is immediately routed through the primary side of the heat exchanger (HX1).

Cold domestic water passes through the other side of this heat exchanger, in a counterflow direction, to maximize heat absorption. The preheated domestic water then passes into the cold inlet of the indirect water heater. This reduces the heat that must be supplied by the mod/con boiler.

For this application, a heat exchanger should be selected that can heat the domestic water, in a single pass, to no more than 10° of the temperature at the top of the buffer tank. An even smaller approach to temperature differences is possible if you want to spend a bit more on the heat exchanger.

I suggest using software such as FlatPlateSELECT (freely accessed at www.flatplateselect.com) to quickly evaluate the performance tradeoffs.

Here’s an example: Assume a situation in which heated water from the buffer tank enters the primary side of the heat exchanger at 120°. Cold domestic water enters the secondary side of the heat exchanger at 50° and 4 gpm. The FlatPlateSELECT software indicates that a 5-by-12-inch 30-plate-deep brazed-plate heat exchanger will yield a domestic water preheat temperature of 110°.

However, increasing the number of plates on the heat exchanger from 30 to 36 yields a preheat temperature of 115°. For the cost of six additional plates on the heat exchanger, there is a 7 percent increase of preheating provided (assuming a total domestic water temperature rise from 50° to 120°).

Another benefit of using the external heat exchanger for domestic water preheating is that the domestic water side can be easily flushed out using the combination isolation/flushing valves shown in Figure 1. If fouled to the point of no return, the heat exchanger also can be replaced without messing with the buffer tank. If ever needed, the piping shown allows a temporary bypass of the domestic water side of the heat exchanger. With the bypass open, cold water would flow directly into the indirect water heater, and all heating would be done by the mod/con boiler.

TAKE WHAT YOU CAN

Because the temperature of the buffer tank is controlled by outdoor reset, the highest domestic water preheat temperature will occur under design load conditions when the buffer tank is warmest. Under partial load conditions, the existing preheat temperature will be lower.

There is a performance tradeoff between keeping the buffer tank temperature as low as possible to maximize COP for space heating versus sacrificing a slight amount of COP to keep the buffer tank warmer under partial load conditions and enable a higher domestic water preheating temperature. The optimal strategy would depend on the exact load requirements for both space heating and domestic water heating.

I suggest setting the lower limit of the outdoor reset controller so the minimum temperature of the buffer tank is in the range of 85° to 90°. This will increase the domestic water preheating effect under partial space-heating loads but only slightly reduce the COP of the heat pump. It also keeps the supply water temperature under partial load space heating low enough that a mixing valve is not needed.

The wiring for the system in Figure 1 is shown in Figure 2.

For maximum water heating capacity, the mod/con boiler should be configured for priority domestic water heating. This temporarily turns off the circulator between the boiler and buffer tank and directs full boiler output to the indirect water heater. The heat pump can still operate to supply heat to the buffer tank, and some of that heat can still be used for preheating domestic water before it enters the indirect.

The preheated water entering the indirect tank will substantially increase both its first-hour DHW capacity and its continuous DHW demand capacity. If this capacity is not needed, I suggest turning down the boiler’s target temperature during the DHW mode. This reduces the heat transfer capacity of the indirect’s internal coil heat exchanger.

The benefit comes from conditions that potentially allow the boiler to operate in condensing mode during the DHW mode. The degree of condensing mode operation depends on the temperature of the water returning to the boiler from the indirect tank, and lower is better. From the standpoint of thermal efficiency, the goal is to find the lowest boiler supply temperature at which adequate DHW delivery capacity is achieved.

What about cooling? Admittedly, this piping and control configuration is best suited for systems that are dominated by heating operation. That said, it can still provide benefits during cooling mode operation. The best configuration depends on how chilled water from the heat pump is used during cooling operation.

If the same buffer tank will store chilled water during the cooling season, circulator (P1B) in Figure 1 needs to be disabled during cooling operation. You could even valve off domestic water flow through the heat exchanger and instead direct cold domestic water directly into the cold port of the indirect water heater.

If the heat pump supplies chilled water to the buffer tank and is equipped with a desuperheater for domestic water heating, the desuperheater circuit should be connected to the indirect water heater. This will redirect about 10 percent of the heat into the indirect water heater that would otherwise be dissipated into the earth loop. Whenever possible, connect the desuperheater circuit so that it works with the coolest water within the indirect tank.

If the buffer tank is not used to store chilled water, the desuperheater circuit can connect to the buffer tank. Again, this sends about 10 percent of the heat into the buffer tank that would otherwise be dissipated into the earth loop and, thus, make it available for domestic water preheating. It also keeps the desuperheater circuit part of the closed hydronic system rather than having it operate with domestic water. The latter is more likely to foul up the surfaces in the desuperheater over time, especially if the water quality is not great.

The approach we’ve discussed allows the best thermodynamic match between the performance characteristics of the heat pump and the availability of a low-temperature load (e.g., domestic water preheating). It also provides the “afterburner” kick you may need if periods of high DHW demand are possible. If you’re planning systems that combine heat pumps and mod/con boilers, perhaps you can work this into your designs.

Publication date: 7/27/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment