CHEMICAL STRUCTURE

PVE is a synthetic lubricant. (See Figure 1.) Synthetic oils are not inherently better than petroleum-based lubricants such as mineral oil, but they do offer the ability to easily modify the formulation and produce molecular weight material with narrow tolerances. This flexibility gives the oil very consistent physical properties.There are a number of items other than the lubricating properties that must be considered when choosing the most appropriate oil for a given application. The miscibility (i.e., ability to mix in all proportions with the refrigerant), viscosity, chemical stability, hydrolytic nature (i.e., tendency to breakdown in the presence of moisture to form acids), hygroscopicity (i.e., tendency to absorb moisture from the atmosphere) and compatibility with other compounds in the refrigeration system are all items that need to be considered.

PVE oil provides equal to or better properties for each of these categories when compared with alternative lubricants such as polyolester (POE) oils for R-410A air conditioning applications. Thus, PVE oil not only provides better lubrication, but also provides additional applied benefits such as improved miscibility, no hydrolysis, and better chemical stability when compared to alternative lubricants.

Figure 1. (Figures courtesy of Idemitsu Lubricants.)

CHEMICAL STABILITY

PVE is a polymer-based lubricant consisting of chains of monomers. The composition and ratio of these monomer units provide some of PVE’s unique properties such as better stability and better lubrication. The polymerization of these chains in combination with specific extreme pressure (EP) additives hold up better under the high pressures typically found at bearing surfaces. The polymer-based chemical structure also makes it easier to tailor the oil with different viscosity and miscibility properties. This, along with the absence of carbon-oxygen double bonds, contributes to the chemical stability found with PVE oil.In contrast, POE oil requires more constituents and carries carbon-oxygen double bonds in its structure that, when fully formulated as an end product, provide for a less stable material.

Figure 2.

ADDITIVE PACKAGES

PVE has also proven to be more effective when used with specific additive packages. Refrigerant oils often rely on additive packages to enhance the lubricating and stability properties of the oil. Typical formulations include anti-wear additives, also known as EP additives, as well as oxidation inhibitors or anti-abrasion agents. The oxidation inhibitors are added to protect system components from oxidizing during normal wear. Anti-wear or EP additives are agents used to increase the lubrication properties of the oil by forming thin oil-soluble films that protect against metal-to-metal contact.The additives have also been found to be more effective at lower concentration levels and tend to stay in the formulation longer. The relatively low additive concentrations result in less impact on other oil properties and also contribute to the stability of the PVE oil.

ELECTRICAL PROPERTIES

The chemical structure of PVE was formulated by combining the ether-based raw materials in such a way as to achieve electrical resistivity comparable to POE and mineral oils. The inherently low polarity of PVE also contributes to the stability of the additive agents.

Figure 3.

HYDROLYSIS

Hydrolysis is a chemical reaction that occurs with moisture and results in the formation of acids that are detrimental to the reliability and performance of the system. It is virtually nonexistent with PVE lubricants, but has been an issue with POE oils in certain applications.Refrigeration systems are often ideal environments for hydrolysis due to the combination of moisture, heat, and other contaminants that can act as catalysts. Once in the system, the acids can start to deteriorate motor insulation and other nonmetallics (e.g., elastomer seals) found in the compressor and other system components. Hydrolysis in POE oils will also result in the production of an iron carbonate soap, which can coat and plug up filters and other system components, negatively impacting the performance and reliability of the refrigeration system.

Figure 2 shows the results of an autoclave test conducted on both POE and PVE oil mixtures with R-410A. The autoclave consists of a sealed test chamber where the contents are subjected to heat, moisture, and pressure. The total acid number (TAN) provides a representation of the acid level in the oil. As the results show, hydrolysis is virtually nonexistent with the PVE oil mixture, which improves system performance and reliability.

Figure 4.

COMPATIBILITY

To a large degree, PVE oil is compatible with other refrigerant lubricants and residual process oils that may be left over from the machining and processing of the refrigeration components. This allows for fewer concerns during the manufacturing process if specific parts are not completely clean from assembly or machining oils. Furthermore, since PVE oil has a similar chemical backbone structure to mineral oil, it allows for an easier retrofitting process from chlorine containing refrigerants such as R-22. During the retrofit of a hydrochlorofluorocarbon (HCFC) system, it may not be necessary to include an extensive flushing procedure; rather, a simple draining of all oil will suffice.In order to determine the compatibility of PVE with those materials commonly used in refrigeration systems, a series of compatibility tests were conducted. The tests were conducted with materials listed in Figure 3.

Figure 5.

Figure 4 shows a variety of physical properties of PVE and POE oil mixtures over a range of relative concentrations. The results show consistent properties over the concentration range from 100 percent PVE to 100 percent POE.

An autoclave test was also conducted on the five concentration levels from 100 percent PVE to 100 percent POE in 25 percent increments. The only significant change observed was the increasing acid levels found at higher POE oil concentration with 100-parts-per-million water content. These results are shown in Figure 5. As a general rule, up to 10 percent residual POE oil in a system will not affect properties of PVE, thereby making system upgrades and retrofits feasible for system operators.

Figure 6.

LUBRICITY

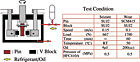

The lubricating properties of the refrigerant oil can be tested using a Falex tester. A schematic of the Falex test is shown in Figure 6, on the left-hand side. The fixture consists of a round pin that is rotated within a twin V-block. Two independent tests were conducted, a wear test and a test to seizure. The conditions for each test are also shown.FALEX TEST - TEST FIXTURE AND TEST CONDITIONS

The Falex test was conducted with R-410A and PVE oil and repeated with R-410A and POE oil. The results for both tests are shown below and demonstrate the superior lubricating properties associated with the PVE lubricant.

Figure 7.

MISCIBILITY

PVE has superior miscibility with R-410A compared to POE. It is completely miscible with R-410A at most operating pressures as shown in the right-hand graphic in Figure 7. PVE is completely miscible on the low side of the system. This helps oil return to the compressor and also limits coating of the evaporator surfaces since the oil remains mixed in and not separate from the refrigerant. PVE also has a smaller immiscible region at higher operating pressures when compared with POE oil. These are significant advantages for OEM manufacturers looking to increase equipment performance at part-load operating conditions.

Figure 8a.

VAPOR PRESSURE VS. SOLUBILITY HYGROSCOPICITY

Both PVE and POE oil are very hygroscopic (i.e., tend to absorb moisture from the surrounding environment) and as such require special handling precautions to limit the amount of moisture absorbed into the oil. While the moisture-carrying capacity of PVE is up to four times greater than POE (see Figure 8), the rate at which the oil will absorb moisture is heavily dependent on the following:• The surface area to volume ratio of the oil. The larger the surface area left open to the atmosphere, the higher the rate of absorption and the ultimate saturation level.

• The amount of time the oil is left open to the atmosphere. Factory production and field servicing procedures should minimize the amount of time the inside of the system is left open to the atmosphere.

Figure 8b.

It is possible to have the oil moisture level measured by sending an oil sample out for analysis. There are several companies that provide this service. Results typically provide moisture content in parts per million in addition to information regarding the acid level and other contaminants.

So, while PVE oil is more hygroscopic than POE oil, the moisture is less of a concern since PVE does not break down to form acids. The moisture can also be removed more easily from PVE oil than from POE oil. While it is never desirable to have moisture introduced into a refrigeration system, the oil-handling procedures used with POE oil systems are generally sufficient for systems using PVE. No additional handling procedures or precautions should be required for PVE applications.

Figure 9.

SUMMARY

Figure 9 summarizes the major characteristics of PVE and POE oil in an R-410A refrigeration system. PVE is equal to or better in all characteristics when compared with POE oil.Because of its lubricating properties and other applied benefits, the use of PVE refrigeration oil for all types of HFC applications has been growing around the world. It is particularly popular in R-410A air conditioning applications in Asia and is also being utilized for CO2 systems. This versatile oil is being specified by more and more refrigeration and air-conditioning system manufacturers around the world. As would be expected from the increased usage, the commercial availability of PVE oil is expanding, and many large distribution wholesalers are beginning to stock the oil to meet the aftermarket requirements.

Publication date:05/03/2010

Report Abusive Comment