These are changes that, if not recognized and addressed from the beginning of a project, could cause wide spread confusion and, in some instances, major redesign, delays, and additional costs.

BACKGROUND

Since 2000, there has been a relatively quiet but significant amount of changes to the codes governing the installation of grease ducts for commercial kitchen applications. There are three major code bodies: the National Fire Protection Association (NFPA); the International Mechanical Code (IMC), which is part of the family of codes developed by the International Code Council (ICC); and the Uniform Mechanical Code (UMC), a part of the International Association of Plumbers and Mechanical Officials (IAPMO) code set. These model codes specify standards and listings developed by independent testing groups, such as Underwriters Laboratories (UL) and American Standard Tests Methods (ASTM).Basic constructions of grease ducts serving Type I hoods require 16-gauge carbon steel or 18-gauge stainless steel. Both types of construction require a minimum 18 inches clearance-to-combustibles when unprotected. For grease duct applications that do not require a fire-rated system, but do come within closer proximity to combustible materials, the codes allow for means to reduce the minimum air space between grease duct and combustible.

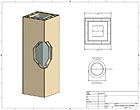

Pictured is a factory-built grease duct, composed of completely assembled components designed to easily connect in the field for complete systems.

CODE HISTORY

Initial protection, where structural or other considerations did not allow room for clearances, was provided by a fire-rated shaft enclosure as defined in model building codes. A one-hour fire-resistive shaft is constructed of a single layer of fire-rated gypsum board applied to both sides of metal studs in the manner described by the building codes. Two-hour rated shafts require an additional layer of fire-rated gypsum board.Proper construction of fire-resistive enclosures was found to be very time consuming, especially where offsets were required. In the early 1990s, the Southern Building Code Conference (SBCCI) created the first alternative fire-resistive enclosure test criteria, based on ASTM E119, ASTM E814, and the internal fire test section of UL1978 (“Test Standard for Grease Ducts”). Flexible wrap systems were tested to the model code acceptance criteria and regional acceptance of these systems was achieved.

Soon after, the Building Official and Code Administrators (BOCA) and the International Conference of Building Officials (ICBO) evaluation services created their own separate acceptance criteria for evaluating alternative fire-resistive systems as pertaining to kitchen exhaust. Flexible wrap systems were tested to these model code acceptance criteria and, as a result, achieved national acceptance as an alternative to a code-prescribed, fire-rated shaft protecting a welded grease duct.

As early as 1994, several manufacturers introduced factory-built grease duct systems composed of completely assembled components designed to easily connect in the field for complete systems. UL 1978 is the standard that provides reduced clearances to combustibles and evaluates non-welded joints as in compliance with NFPA, ICC, and IAPMO requirements. UL 1978 does not evaluate fire-resistive enclosures or building materials. It is solely used for factory-built ducts that are completely assembled in the factory, listed and labeled, and subject to periodic inspections by the listing agency to ensure materials and final construction is equivalent to the products tested per the UL 1978 standard.

Clearances must be displayed on the UL label and installed in accordance with the clearances specified. UL 1978-listed grease ducts must be installed per the manufacturer’s installation instructions that meet the minimum requirements of the standard.

Pictured is the layout of a fire-rated shaft, built around a grease duct. A one-hour fire-resistive shaft is constructed of a single layer of fire-rated gypsum board applied to both sides of metal studs in the manner described by the building codes. Two-hour rated shafts require an additional layer of fire-rated gypsum board.

THE BIG CHANGES

In January 2009, UL, Intertek Systems, and the International Code Council Evaluation Services (ICC-ES) are jointly abandoning all listings or evaluations that are based on SBCCI- and BOCA-acceptance criteria, both of which use the internal fire test portion of UL1978, which addresses reduced clearances for field-applied flexible wrap systems. Once abandoned, the only listing for flexible wraps applied to grease ducts will be ASTM E2336-04.For non-fire-rated grease duct applications (grease ducts that do not penetrate a fire-partition), any edition of any code requiring a listed product to reduce clearances can only allow flexible wraps installed in compliance with ASTM E2336-04. Factory-built systems listed to UL 1978 for reduced clearances are not affected by this change and may be used in installations where a fire-resistive enclosure is not required.

It is also important to note that listed, single-wall, factory-built grease ducts will not be allowed to be enclosed or wrapped with one or more layers of flexible wrap material unless the factory-built grease duct listing and the flexible wrap manufacturer’s listing clearly states such system has been evaluated to UL 1978.

This is not a new development based on changes to the national codes. However, the UL guidelines for UL 1978 test standard is clear on this issue and code officials having jurisdiction should be aware to limit liability of a non-listed system that results from combining the two products.

UL 2221 (“Tests of Fire Resistive Duct Assemblies”) and ASTM E2336-04 (“Standard Test Methods for Fire Resistive Grease Duct Enclosure Systems”) are the standards applied to alternative construction methods for fire-resistive shafts. Compliance with these standards provides an enclosure that is rated at zero-inch clearance to combustibles. When penetrating a fire-rated partition, the penetration must be fire stopped to the rating of the partition.

BOTTOM LINE

To summarize, effective January 2009, all flexible wraps must be applied in accordance with ASTM E2336. This code specifies a product listed to a nationally recognized standard. All other acceptance criteria and regional or nationally recognized approvals are abandoned.Factory-built systems must comply with UL 2221 when used as an alternative-shaft enclosure with zero inch clearance-to-combustibles. Factory-built systems can continue to be installed per their listings for reduced clearances to combustibles, as listed in UL 1978, where a fire-resistive enclosure is not required.

Some words of advice to all concerned parties:

•Architects & structural engineers:Grease ducts are now getting larger. Allow space for installation. Design systems to minimize offsets.

•Mechanical engineers:Be sure to include information on your drawings, addressing code compliance, cleanouts, inspection ports, etc.

•Specifiers:Include material requirements, flues, casings, insulation thickness (if appropriate), and code compliance in your specifications.

•Contractors:Know your codes and requirements in the area having jurisdiction over the project. Currently, flexible wrap systems listed per ASTM E2336 require two layers of flexible wrap for compliance.

These changes were brought about for the No. 1 reason for change: safety. Therefore, take note of the changes.

Publication date:10/13/2008

Report Abusive Comment