Home » Keywords: » ammonia refrigeration

Items Tagged with 'ammonia refrigeration'

ARTICLES

Grocers Share Concerns Over Alternative Refrigerants

Food retailers cite problems with CO₂ and other low-GWP refrigeration systems

Read More

CO2/Ammonia Cascade System Proves Effective in Retail Settings

Supermarkets can future-proof their refrigeration systems using natural alternatives

February 5, 2018

EPA Delays RMP Amendments Until 2019

Existing Risk Management Program will remain in effect as recent amendments are reviewed

Read More

Data Center Managers Strive to Conserve Resources, Energy

New solutions reduce power, water, and refrigerant use

Read More

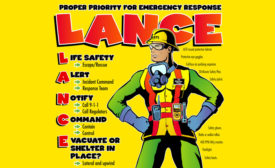

The First 10 Minutes Are Critical in an Ammonia Release

Knowing what not to do is just as important as knowing what to do

Read More

Should Ammonia Exit ASHRAE Standard 15?

IIAR 2 may be a more appropriate safety standard for the B2L refrigerant

Read More

Why R-32 May Be the Refrigerant of the Future

All options have pros and cons, but R-32 makes a good case for itself

Read More

Navigating the Aisles of Change

While changes keep coming for supermarkets, the HVACR industry keeps answering the call

Read More

Scanning the Supermarket and Restaurant Horizons

HVACR news and advances from two dynamic market sectors

Read More

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing