Moving all that air can generate a lot of noise and lead to the need to directly exhaust that air. In many cases, exhaust is accomplished simply by opening windows, which can introduce wind-borne dust and raise security concerns.

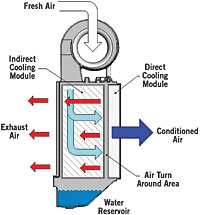

A new, 3-ton equivalent evaporative cooler, called the OASys (see Figure 1), was designed to address these problems by using both direct and indirect evaporative cooling.

This two-pronged approach is designed to produce a greater temperature drop, thereby reducing the volume of air required. According to Davis Energy Group, an HVAC consulting company that developed the system with Speakman CRS, the OASys also uses less energy than conventional evaporative coolers.

Energy Savings Touted

According to Davis Energy Group, its OASys packages heat exchangers and airflow paths in a unique way, all designed to provide energy-efficient operation, as well as improved comfort.In regard to energy and demand savings, the company said its OASys features an efficient, new counterflow heat exchanger, an energy-efficient electronically commutated motor, and "an innovative routing of air within the unit that effectively adds a third stage to the cooling process." (See Figure 2.).

According to the company, this results in an annual energy savings of 89 percent to 95 percent, and demand savings of 80 percent to 90 percent, compared with vapor-compression air conditioners.

Turning to seasonal energy-efficiency ratios (SEER), the California Appliance Efficiency Regulations established a minimum SEER of 9.7 for vapor-compression, single-package units.

However, according to Davis Energy, its OASys offers a SEER of better than 40. Still, this rating is limited as a measure of efficiency improvement because the OASys was tested under different conditions than the Air-Conditioning and Refrigeration Institute (ARI) uses for testing conventional air conditioners.

Although the OASys still requires the use of dedicated exhausts, the reduction in airflow makes it easier to rely on passive pressure-release exhaust vents that can be mounted in the ceiling, eliminating the need to open windows.

As a result, the OASys cools outdoor air in an indirect evaporative stage before sending it through a direct evaporative stage. Therefore, the system is designed to introduce less moisture into a building than a conventional, single-stage, direct evaporative cooler. (See Table 1.)

Davis Energy said its OASys uses a molded plastic cabinet that is resistant to corrosion. It also said with an uninstalled cost of around $2,500, the OASys will be competitive with comparable air conditioners. It believes this should lead to an immediate payback in regions where evaporative cooling can cut energy consumption.

Applications

According to Davis Energy, its OASys is suitable for residential applications in hot and dry climates, which includes many of the U.S. Southwest and Mountain States. Applications where indoor air quality (IAQ) is especially important, such as modular classrooms, are also good candidates for this technology, the company said.

Under the present California codes and standards, either direct or indirect/direct evaporative coolers may be used, subject to the eligibility and installation criteria cited in the current Alternative Calculation Method (ACM) Manual. For these criteria in the ACM Manual, a direct system is considered equivalent to an 11-SEER vapor-compression air conditioner, and an indirect/direct system is considered equivalent to a 13-SEER unit, with either type of system using R4.2 to R8 ducts in the attic, depending on climate zone.

Field-testing is currently under way, with 20 units installed in California, Utah, Colorado, and Arizona. Speakman CRS, a manufacturer of clean and sustainable technologies, anticipates going into full production with the OASys late this year or early 2006.

According to Speakman CRS, future products may combine the OASys with a heating element or a small vapor compression air conditioner to enable use of the two-stage evaporative technology in a broader range of conditions.

Detailed reports on this project are available online at www.energy.ca.gov/pier/buildings/projects/500-98-022-0.html. For more information, contact the California Energy Commission at www.energy.ca.gov/pier.

Publication date: 11/14/2005

Report Abusive Comment