Geothermal heat pump systems not only offer building owners the best in comfort and low operating costs, they also offer higher profits for contractors. No gas lines, flue pipes, refrigeration line sets, condenser, nor electrical wiring to the outdoor unit — that’s a lot of avoided costs.

In new construction, the earth loop can be installed anytime during construction; the final installation can be done in one day.

Retrofit or change-out jobs offer many more opportunities for contractors. The units are available in upflow, downflow, indoor split, and outdoor split configurations.

Geothermal systems are easy to install, especially when replacing an older forced-air system.

Geothermal systems can be installed in locations incompatible for natural gas or propane furnaces because there is no combustion, and no need to vent exhaust gases. In fact, geothermal components can be retrofitted to existing heating equipment for those who desire the redundancy of a dual-fuel system. The existing, conventional furnace can be kept as a backup heat source in extremely cold climates.

The availability of outdoor geothermal split units makes change-out opportunities even more attractive, because the outdoor geothermal unit replaces the existing condenser unit. Earth loops are connected to the outdoor unit directly. No inside loop piping is needed, and the existing electrical service can be reused.

Many dealers have reported that they can change out an existing conventional system in one day, including earth loops.

How Do Geothermal Systems Work?

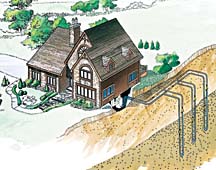

The earth absorbs almost 50 percent of all solar energy, so it remains at a nearly constant temperature of 50 degrees to 70 degrees F, depending on the geographic location. Working with an underground loop system, geothermal heating and cooling systems utilize this constant temperature to exchange energy between the building and the earth as needed for heating and cooling.During heating season, fluid circulating inside a sealed underground loop system absorbs heat from the earth and carries it to the geothermal unit and into the building as warm air. In cooling season, the system reverses the process and expels heat from the building into the cooler earth via the same loop system.

This heat exchange process is a natural, highly efficient way to create a comfortable indoor climate.

Geothermal heat pumps are durable and highly reliable because they have few moving parts. System components typically are installed either indoors or underground, so they are not exposed to theft, vandalism, or environmental conditions that can shorten system life.

With periodic filter changes, geothermal heat pumps can provide owners with many years of reliable operation. In fact, many geothermal units installed 30 to 40 years ago are still in operation. Earth loops can be expected to last a minimum of 50 years.

Loop Configurations

A variety of loop configurations are available; the type that is used depends on soil conditions and the amount of land available. Earth loops are sized to the load of the building and can be installed horizontally or vertically in the ground, or sunk in a nearby body of water.Depending on weather conditions, the fluid contained in the sealed loop can be water or a mixture of water and environmentally safe antifreeze. Although the fluid in most types of loop configurations circulates in a closed-loop system, open loops are sometimes used where sufficient groundwater exists and local codes permit.

Roughly 400 to 700 feet of pipe is installed per ton of heating-cooling capacity. The pipe may be coiled in order to fit more pipe into a given trench area. The trench is carefully back filled to ensure contact between the pipe and the earth.

Pond or lake loops are submerged to about 12 inches off the bottom and require less trenching, but the pond or lake must maintain a minimum depth of 8 feet year round and must have sufficient surface area. Pumping water directly from a pond or lake is not recommended.

Bourn is with ClimateMaster Inc., 7300 S.W. 44th St., Oklahoma City, OK 73179. For more information, call 405-745-6000 or visit www.climatemaster.com.

Publication date: 08/25/2003

Report Abusive Comment