In his keynote speech, James Connaughton, chairman of the White House Council on Environmental Quality, talked about a “clean energy future.” When it comes to energy, he said, “Newer is cleaner, safer, and, over time, tends to be more affordable.”

In integrating environmental issues into everyday management, he said, a key issue is energy efficiency. President Bush’s National Energy Plan features energy efficiency and renewable energy, he noted. “More than half of the items in the energy plan refer to efficiency and renewable energy.”

The U.S. Department of Energy (DOE) was mandated to carefully examine energy-efficiency measures to see where it should best use its funding.

In the future, such things as solar shingles and high-efficiency air conditioning equipment may provide net-zero energy use buildings. Homeowners and building owners may be able to sell excess power back to the utilities. Peak load shifting will be done more seamlessly.

Fuel cells, combined heat and power systems, wind power, and solar energy are all key technologies, Connaughton said. And the federal government is looking to implement incentive-based ways to move ahead. “We can’t meet our energy goals by conservation alone.”

The creation of a new high-technology energy infrastructure will provide for a more dependable energy supply, he concluded.

REPLACING CFC CHILLERS

Stephen O. Andersen of the U.S. Environmental Protection Agency (EPA) talked about a new program to push for quicker replacement of all CFC-11 and -12 chillers. Replacing them “saves money as well as protects the environment,” he said.Called the Building Air Conditioning Climate Protection Partner-ship, Andersen said that a number of organizations and companies are involved in this effort, including such equipment manufacturers as Carrier, McQuay, Trane, and York.

The bottom line, he stated, is that 50,000-plus chillers are still operating on CFCs in the United States, “wasting energy and depleting the ozone layer.” One year of CFC refrigerant emissions does more damage than HCFCs and HFCs would do in 30 years of emissions, he proclaimed. Regarding the cost, he said that there is a 3- to 5-year payback on conversions.

The most commonly used new refrigerants for large building applications are HCFC-123 and HFC-134a. Ammonia or hydrocarbon systems may be considered, Andersen stated, if allowed by code and where they can safely provide higher energy efficiency.

The EPA wants to help “translate environmental technical arguments into deal-closing sales calls,” he said.

DISNEY’S ‘ENVIRONMENTALITY’

In his presentation describing Walt Disney World’s implementation of the Energy Star® buildings program, Paul J. Allen, P.E., chief engineer, energy management, detailed how the company balanced first cost and life-cycle analysis.In Disney’s “Environmentality” program, achieving energy-efficient buildings includes going after the lowest cost fuel and power, installing energy-efficient products, and applying energy management systems to reduce the hours of operation, he said.

The Energy Star buildings program includes:

1. Green Lights upgrades;

2. Building tuneup;

3. Load reductions;

4. Fan system upgrades; and

5. Heat and cooling plant upgrades.

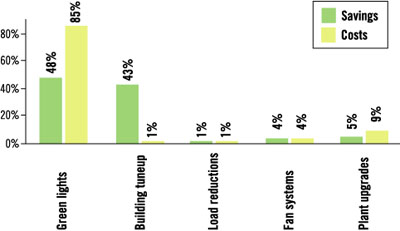

Applying the EPA’s Green Lights upgrades saved a considerable amount on electricity usage. This item brought 48% of the energy cost savings achieved at Disney, said Allen. However, it also required 85% of the corporate funding for the program. As the accompanying chart shows, just 1% was spent on building tuneups, but this item provided 43% of the energy savings, a substantial return on investment.

He related that the company’s building tuneup process includes:

Allen said that you should submeter chiller plants to get their efficiency at the best possible level. At Disney, he can check on chiller efficiency every hour of the day.

When changing temperature setpoints, he remarked, “Slow and steady wins the race.” Make changes gradually to avoid customer complaints.

In concluding, Allen said it is important to design for energy efficiency. Evaluate energy-saving equipment using building simulation models. It is also important to operate equipment efficiently, he declared. Optimize setpoints and repair defective controls. He also recommended monitoring utility usage, getting daily/monthly reports, and using an Intranet and Web browser to access data.

CHILLER CONVERSION IN DEVELOPING COUNTRIES

Steve Gorman of the World Bank discussed CFC chiller phase-out in developing nations. The World Bank assists these countries financially in making chiller conversions.There are demonstrated benefits in changing over in terms of reduced emissions and energy savings, he said. The financial return depends on several application factors, including equipment/installation costs, cooling load, hours of operation, and others. A sample return on increased efficiency is 20% savings on total building energy use. Other advantages are that conversion reduces peak load requirements, saves on maintenance, and provides “public good” benefits by reducing pollutants.

Over half of the CFC chillers in the U.S. have been phased out, said Gorman. HCFCs dominate as the refrigerant of choice in the U.S. HFCs dominate in Europe.

Developing countries have a 10-year grace period to implement the provisions of the Montreal Protocol, he commented. Pilot chiller conversion programs have been initiated in Mexico and Thailand.

The barriers to replacement in these nations, he noted, include:

Methods of promoting replacement include:

ENERGY EFFICIENCY IN FEDERAL BUILDINGS

Elizabeth Shearer, director of the DOE’s Federal Energy Management Program (FEMP), related how the U.S. government is looking at and applying energy efficiency in federal buildings.The Bush administration mandated that the federal government should lead by example. The government spends $7.4 billion on energy each year, she said. To promote efficiency in federal buildings, the FEMP program consists of setting goals, planning, measuring performance, reporting progress, and recognizing leadership.

The federal goal, stated Shearer, is to reduce energy use 30% by 2005, and 35% by 2010, in standard buildings. The government would also like to expand the use of renewable energy and increase water conservation.

The government currently uses 0.4% renewable energy, she said. The goal is to move that number up to 2.5%. The government is now installing more solar and geothermal systems, she noted. Another goal is to reduce greenhouse gas emissions 30% by 2010, relative to 1990 levels.

The federal government wants new buildings to be energy efficient and sustainable, she explained. To achieve this, it is applying alternative financing options, such as energy-saving performance contracts and utility energy-saving contracts.

FEMP provides a great deal of technical assistance to government agencies for design, using renewables, applying distributed energy, etc. Its software tools, such as building life-cycle cost analysis, are used not only within the government but also by the private sector, Shearer said.

CONNECTING WITH BUILDING OWNERS

Ron Burton, vice president, government affairs, with the Building Owners and Managers Association (BOMA) International, stated, “We represent the people you need to work with” to improve building efficiency. “We’re in an era of cooperation on these elements to bring these things together.”Energy cost is the single largest expense of building operation, he said. Thirty-one percent of total operating cost is energy. And energy expense goes up every year, he added.

The bottom line is return on investment for BOMA members. Owners want a high rate of return on equipment upgrades. Life-cycle costing is important for long-term owners, he pointed out.

BOMA urges a proactive stance on energy efficiency, Burton said. “We want to lead rather than have regulation stuffed down our throat.” The association supports tax incentives for energy efficiency. The recent economic stimulus legislation passed is good for building owners, he remarked.

Use of renewable energy and cogeneration “are not pie in the sky,” said Burton. He’s starting to see use of these in buildings and he’s also seeing increasing use of the Energy Star program.

Because of Sept. 11, building owners are doing such things as filter upgrades, fan motor upgrades, and making sure that dampers are working properly. These can lead to other equipment upgrades, he stated. “BOMA is doing its part to push things forward in an energy-efficient and environmentally conscious way.”

Publication date: 05/13/2002

Report Abusive Comment