Bob receives a call from the dispatcher that a new customer has called. It is 95 degrees outside and the homeowner's air conditioner is not working. The fan outside is on and the fan inside is on, but no cool air is coming out.

When Bob arrives, the customer says, "The unit stopped last week and a service man from another company came out and made the repair. I did not like the service technician. He was very unprofessional. He made a quick repair and left."

Bob asks, "May I see the service ticket?"

The customer shows him the ticket where the work is described. The ticket reads, "Suction line vibrated and had a large leak. Soldered the leak and charged the system."

Bob goes to the unit to see if he could determine where the leak was. The condenser fan is running, but the compressor is not running. He removes the compressor access door and finds a patched area on the suction line where the cabinet had rubbed a hole in the line. It is patched with 15 percent silver solder and looks like a good patch. The line had been moved to where it would not touch the cabinet anymore. About that time the compressor starts and Bob could hear it begin to work. He reaches over and feels the suction line and it is cold. It seems a little too cold as though it has liquid refrigerant in it. The unit continues to run. He touches the liquid line. It is very hot.

Bob is standing there scratching his head when Btu Buddy appears. "What seems to be the problem, Bob?"

"Things aren't adding up, the unit seems to have too much refrigerant because the suction line is cold, but the liquid line is hot. It seems that if this were an overcharge, the liquid line would be cool from extra subcooling."

Btu Buddy then says, "I think it is time to put your gauges on. Just shut the system down until you are ready."

About that time, the compressor shuts off, but the condenser fan keeps running.

Bob says, "Well, I guess that solved that; the compressor shut itself off."

Btu Buddy then says, "Turn off the power for a moment and let's try something."

Bob turns off the power. "Now what?"

Btu Buddy says, "Remove the common line to the compressor and tape it, then turn on the condenser power again. We want the fan to run, without the compressor."

Bob does as Btu Buddy suggests and asks, "What now?"

Btu Buddy says, "Put your gauges on the high and low side."

Bob fastens the gauges.

Bob says, "No, what do you mean?"

Btu Buddy says, "What do you think the readings should be? This is an R-22 system. Think for a minute, the outdoor unit has liquid refrigerant in it and the fan is running, passing 95 degree F air over the coil. What could that pressure be? The indoor fan is running and passing 85 degree F air over the coil. What could the pressure be?"

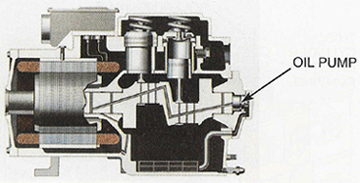

(Figure 1 is an illustration of a standard-efficiency system and a high-efficiency system operating under design conditions.)

Bob thinks for a minute and says, "Well, the unit has a capillary tube metering device that should equalize between the high and the low side. I would think that most of the liquid would eventually move to the indoor coil where it is the coolest. The high-side pressure should not exceed the level corresponding to 95 degrees, which would be 182 psig. The lowest the pressure should be would correspond to the air temperature passing over the indoor coil, which is 85 degrees or 155.7 psig. Hey, would you look at that, the pressure is 193 psig."

Btu Buddy asks, "What could that mean?"

Bob responds, "Either the unit has some air in it or there is another refrigerant in it."

Btu Buddy then says, "Read the last repair ticket carefully."

Bob says, "He mentioned a low side leak, but did not mention that he had evacuated the system. I bet this system has air in it. The system would have run when the charge became low because it doesn't have a low pressure shut off control. The only thing that would have shut the unit down would be the motor temperature thermostat."

"Good observation," remarks Btu Buddy. "Now what?"

Bob answers, "This system needs the refrigerant recovered, a drier added to the liquid line, then it needs to be evacuated and charged."

"Correct," Btu Buddy says.

Bob goes to the homeowner and explains what needs to be done, without saying bad things about the other service technician. She says to Bob, "Repair it to the best of standards. You don't have to say anything about the other technician. I already had him figured out."

After the repairs are made and the system is started up and running, Bob says, "That was a good find. When we arrived, the compressor was running at part capacity and shutting off from time to time because of compressor internal overload. It would then start up and run for short periods of time. I still do not fully understand how the air acted in the system."

"A more immediate response is due to the oxygen gas and the nitrogen gas which will not condense at the temperature and pressure that the system operates. They will move quickly to the condenser where they will not condense. The system has a liquid seal between the low- and high-pressure side (the expansion device), so the non-condensing gases stay in the top of the condenser, taking up condensing space. Effectively making the condenser undersized, the head pressure rises, causing the compressor to shut down on motor temperature thermostat."

Bob says, "So what you are telling me is that an immediate reaction caused high head pressure and a safety shut-down, and if there were just a little air in the system, long term damage would occur due to electroplating. I guess we were lucky that the air in the system was great enough to cause us to make a repair when we did."

Btu Buddy says, "Yes, in the long run, the system could have suffered with only a small amount of air." He then says, "Well, the system is running now with the correct charge of only refrigerant and oil. The system is clean and dry and should last for years without problems."

Bob goes to talk to the customer before leaving and says, "Your system is in good shape and should provide you with many years of good service."

She says, "Thank you for being very professional about this repair. We will be using your company from now on."

As they are driving away, Btu Buddy says, "Another customer that likes your services. They keep adding up. Your company is noticing the business that you are bringing to them."

Bob says, "Thanks for the suggestions and help."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Thomson Delmar Learning. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or billj@carolina.rr.com.

Publication date: 07/24/2006

Report Abusive Comment