At the AHR Expo this year, Emerson highlighted solutions aimed at helping contractors and OEMs achieve regulatory requirements with ease and meeting the need for highly efficient, reliable systems. The featured products at the booth supported sustainable initiatives such as decarbonization, natural and low-GWP refrigerants, and electrification, and the company also celebrated the Copeland brand’s 100-year milestone.

“With more than 200 million compressor installations, Copeland products continue to offer reliability through rigorous testing and field longevity over a century-long history of inventiveness,” said John Schneider, president of HVACR technologies, Americas at Emerson. “As the company introduces the next-generation scroll platform, the Copeland K7 compressor series is poised to support OEMs in future system design while also addressing contractor needs for reliability and ease of install in the field.”

New Solutions

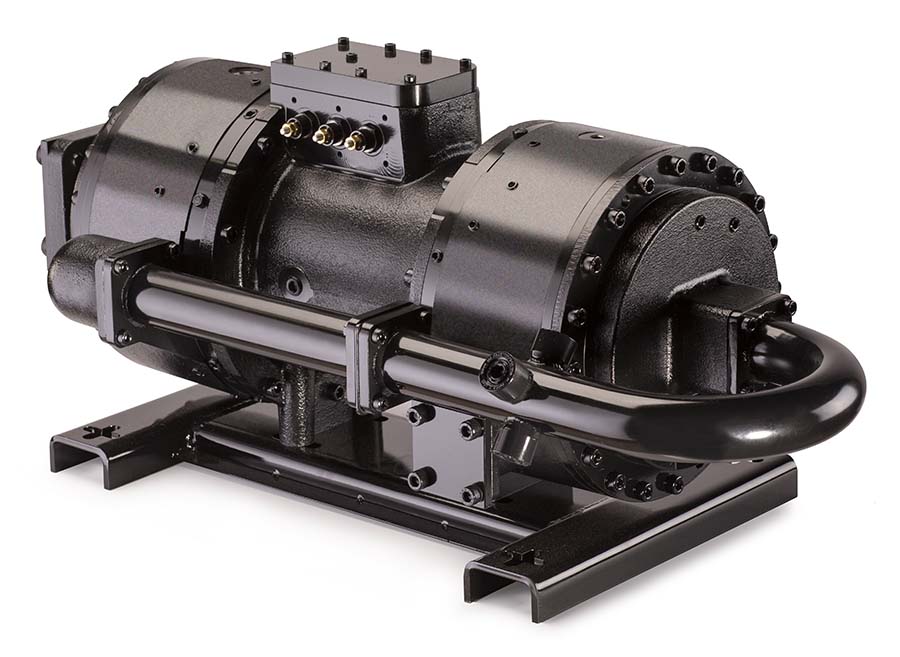

NO OIL: Copeland’s oil-free centrifugal compressor is a modular product that is designed for oil-free solutions in chiller applications. (Courtesy of Emerson)

Emerson highlighted a number of products focused on environmental sustainability, technician productivity, and safety in the field. Some of the key products displayed included three AHR Innovation Award finalists: the Copeland oil-free centrifugal compressor featuring Aero-lift bearing technology; the Copeland horizontal, variable-speed, scroll compressor for commercial refrigeration; and the Ridgid pipe saw.

The new Copeland oil-free centrifugal compressor featuring Aero-lift bearing technology enables oil-free solutions in chiller applications through a step-function reduction in the complexity required to operate oil-free centrifugal compressors. It offers increased efficiencies in chillers, designs optimized for lower-GWP refrigerants, and a scalable product platform to address upcoming regulations, with a broader-range envelope while increasing turndown.

NEW TECHNOLOGY: Director of new commercial products, Mike Oakley, shows off the new Copeland oil-free centrifugal compressor featuring Aero-lift bearing technology. (Staff photo)

According to Mike Oakley, director of new commercial products at Emerson, Aero-lift bearing technology provides a technology differentiator for Copeland oil-free centrifugal compressors. “It's a low complexity solution that allows us to approach and deliver oil-free differently. It offers all the benefits of oil-free, but we're coming at it with a unique technology angle that allows us to serve the industry differently, which will allow our customers to differentiate and position their products when it comes to compressor, electronics controls, and their system solutions.”

Another new product, the Copeland horizontal, variable-speed, scroll compressor, offers a solution for more sustainable compression technology within the commercial refrigeration sector. For manufacturers of self-contained, reach-in coolers and freezers, display cases, and walk-in coolers, this low-profile, variable-speed solution delivers an ideal combination of energy efficiency, low GWP refrigerant options, reliability, and design flexibility, said Schneider.

“Today, there are very few design options left to help OEMs achieve Energy Star certification or address future energy efficiency reductions mandated by the Department of Energy (DOE) on commercial refrigeration equipment,” he said. “By integrating a Copeland horizontal, variable-speed, scroll compressor in their self-contained equipment, OEMs can significantly improve system energy efficiency and performance.”

In addition, as refrigerant regulations evolve, interest in self-contained, distributed refrigeration systems that utilize lower-GWP alternatives will continue to grow. Schneider noted that the Copeland variable-speed, horizontal, scroll compressor will help OEMs meet these low-profile design challenges, while allowing end users to adopt sustainable refrigeration strategies.

The Ridgid pipe saw enables contractors to cut pipe quickly and efficiently, as a unique clamping design secures the tool to pipe up to 12 inches in diameter, resulting in a quality cut in minutes. Configured to cut steel and stainless steel and with a quick switch to optional blades, it can cut plastic and cast steel on the job site. The pipe saw eliminates the need to struggle with gas tanks, open flames, or handle loose tools, as it secures to the pipe with a rugged three-point roller system.

FIXED SPEED: The new Copeland ZPKZ 6-40 ton fixed speed scroll compressor for commercial applications is designed for lower-GWP refrigerants. (Courtesy of Emerson)

Emerson also highlighted several recent product launches, including the Copeland ZPK7 single-speed (fixed) scroll compressor and the Copeland ZPSK7 two-stage scroll compressor lineup, both for residential and light commercial HVAC applications. Some key solutions for CO2 applications included Copeland EVM/EVH Series variable-frequency drives, Copeland 4MTLS transcritical semi-hermetic compressor, Copeland ZOD subcritical scroll compressor, and Lumity™ E3 supervisory control.

Emerson had a number of other products in its booth from brands such as Copeland, ASCO, Lumity, Sensi, Ridgid, Greenlee, Dixell, Cooper-Atkins, Thermo-O-Disc, Verdant, and White-Rodgers.

Refrigerant Transition

Of course, one of the more popular topics discussed at the AHR Expo was the regulation of refrigerants, which continues to be a source of great uncertainty in the HVACR industry. Indeed, the refrigerant transition may be a bit of a challenge on the commercial refrigeration side, said Katrina Krites, director of strategic marketing, cold chain at Emerson, because many food retailers are in different phases of the process, as well as in their knowledge base.

“There's a lot of complexity relative to how the regulations are going to play out in different areas,” she said. “In places like California, people are going to CO2 more for their new stores, but in the rest of the country? Not necessarily. Yes, large retailers are moving that way, but the challenge for us is that everybody is on a different part in their journey.”

Fortunately, with the passage of the AIM Act, more people are beginning to understand that the refrigerant transition is here to stay, said Rajan Rajendran, global vice president of environmental sustainability at Emerson. The question then becomes, what choices do end users have for air conditioning and commercial refrigeration equipment?

“In air conditioning, we’re able to provide two of the answers — R-32 and R-454B — and most OEMs have announced their choice,” said Rajendran. “On the commercial refrigeration side, it's not like one or two OEMs, it's not like one or two refrigerants. There are natural or synthetic refrigerants; there are A2Ls and A1s; there are high pressure, medium pressure, and low pressure; there’s CO2 to ammonia or propane. So the choices are many. In the last six months, people were asking what refrigerants are available besides CO2 and propane. Now more people are realizing that there is a whole host of A2L refrigerants, so they realize there are choices below 300 GWP and below 150 GWP in commercial refrigeration that could be nonflammable or flammable. Those are the kinds of things that we need people to start thinking about.”

There is no doubt that new energy-efficiency requirements for commercial refrigeration, as well as certain residential and commercial equipment, are driving the evolution of refrigeration and air conditioning solutions, said Schneider.

“We continue to see the trend in shifting to low-GWP refrigerants, A2L refrigerants, and higher-efficiency systems to meet these upcoming regulations,” he said. “We have been and will continue to innovate products that help overcome these challenges, providing solutions that will lessen the environmental impact as well, as help enable contractors and OEMs meet federally mandated requirements.”

Report Abusive Comment