Home heating has changed dramatically from the days of the wood stove, and with each change, new levels of heating technology have been deployed. The current iterations of heating equipment bring with them improved approaches to comfort in the cold season. That means contractors and technicians alike are not only preparing to keep their customers safe but also looking at what it takes to achieve excellent performance from high-end HVAC equipment.

High-End Maintenance

The maintenance skills required to install and maintain high-end HVAC equipment vary. The basics often remain the same, but added features can require an understanding that those working with standard residential heating equipment may not already grasp.

“Contractors need to make sure that their technicians have received all the pertinent installation training from the manufacturer,” said Derrick Paul, director of sales, airstage VRF, Fujitsu General America. “They need to follow the procedures that were provided in the manufacturer’s class. With Fujitsu high-efficiency heat pumps, there are no special maintenance tasks required other than those you would typically expect for a standard heat pump or air conditioning system. These tasks are maintaining a clean filter, regular coil cleanings, and regular cleaning of the condensate drains.”

CONSTANT UPDATES: The Carrier Infinity® 24 heat pump with Greenspeed® intelligence sends software updates over a Wi-Fi connection so the system is always up to date.

“High-end products deserve a high-end skill set when it comes to installing, maintaining, and servicing them,” said Todd Nolte, senior director, product strategy and regulatory, residential HVAC, Carrier. “Learn about the equipment before getting to the jobsite. This maintains the level of professionalism that purchasers of high-end products expect from you, your company, and the brand you are installing.”

To help with the instruction of contractors and technicians, Nolte suggested that they take advantage of the training materials available from Carrier’s My Learning Center, HVAC distributors, and trade associations such as ACCA.

“Take advantage of these resources and never stop learning,” he said.

High-end HVAC systems will often help the technician maintain the system with different diagnostic features, status reports, and communication devices. Nolte suggests that the best thing a technician can do is to not only get smart devices online for customers, but to also take the time to ensure that customers understand their new equipment.

“This should be part of the installation process and will ensure that the equipment receives the latest software updates, reduces homeowner call-backs, and provides for a better overall customer experience,” said Nolte. “One of the benefits with latest-generation equipment is the ability to provide over-the-air software updates. For example, our Infinity® 24 heat pump with Greenspeed® intelligence sends software updates over a Wi-Fi connection, so the system is always up to date. This allows for the most current and optimized operating performance.”

This product offers efficiencies up to 24.0 SEER, 15.0 EER, and HSPF up to 13.0.

Using the Carrier Service Tech app in tandem with this equipment, technicians can perform routine service checks via Blutooth. With their smart devices, they can confirm if a unit is running at peak performance at any time for their customer. Not only does this save the technician time, but it can also be considered an add-on service to help differentiate a contractor.

Fresh Air Demand

Ventilation and IAQ are two closely related yet different topics. The former refers more specifically to the amount of air being processed through the entire system, whereas IAQ hones in on how clean that air is. Current building codes can increase the need for fresh air. Paul explained that the fresh air requirements are not for the sake of heating system efficiency but because of how tight some of the new homes are being built. With that comes an increased demand for ERVs or HRVs in high-end HVAC installs.

“The addition of ERV or HRV technologies to high-end systems can provide better comfort, efficiency, indoor air quality, and humidity control over adding ventilation alone,” said Nolte. “There are numerous health and safety benefits to increased ventilation, but those benefits can come at a cost to comfort and energy usage. Adding an ERV or HRV helps to control the amount of outside air coming into the building, temper air for reduced system load, and more effectively manage the humidity levels in the building.”

Custom-built homes are one example of high-end arenas that not only require increased fresh air, but are also in need of custom heating and cooling project applications.

Two years ago, Ferguson Enterprises’ VRF division became involved with a system design of a 10,000-square-foot new construction residential project in Paramus, New Jersey. Already well along in the design process, the home featured sweeping stairways, spacious rooms, finished third-story spaces, and an indoor pool.

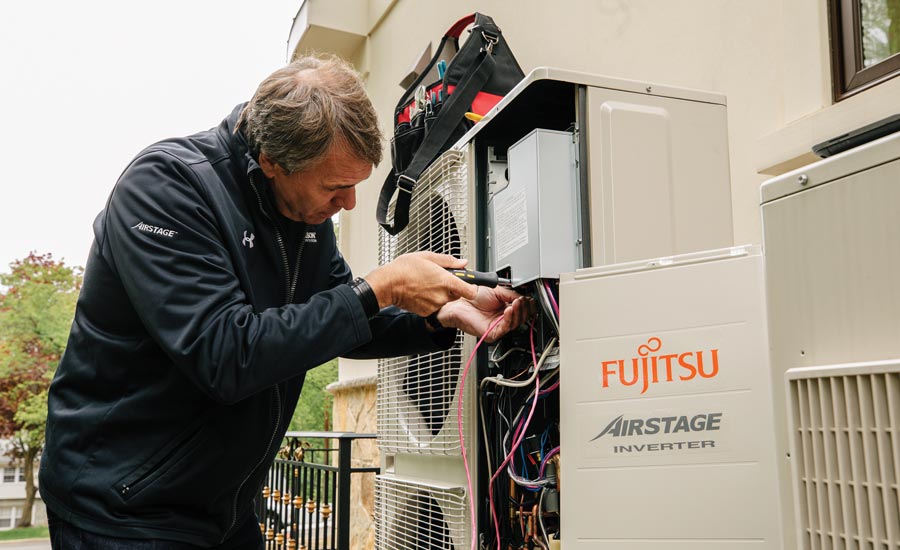

HEAT PUMPS HEAT TOO: Some contractors specify Fujitsu Airstage VRF systems for air conditioning and shoulder-season heat.

“The homeowner wanted in-floor heat, so we knew from the beginning that there would be two independent systems — three if you count the natatorium system,” said Karol Tomaszewski, VRF sales and technical advisor at Ferguson. “For air conditioning and shoulder-season heat, we supplied several Fujitsu Airstage VRF systems.”

He explained that the details of this job would have looked strikingly different had it been designed a decade or 20 years ago.

“It’s amazing to see how HVAC technology has evolved and also how the levels of comfort and efficiency have soared.”

Electric Heat

The next three to five years will bring changes to the high-end market, especially with regard to fuel type. Outside of HVAC in general, a trend toward broad-use solar power for homes is increasing. This, in turn, is pushing for the electrification of the systems used in the home. Nolte expects this trend to continue to accelerate.

“This could drive more demand for inverter-driven heat pumps,” he said. “In some regions, electrification could also drive an increase in the application of dual fuel systems with a high-efficiency furnace and heat pump.

Paul said that growing concerns for climate change has spurred a national movement toward electrification.

“Communities are moving away from fossil fuels as a source of heating,” he said. “Without the ability to burn fossil fuels for residential heating, highly efficient electric sources of heat are needed.”

Report Abusive Comment