During maintenance of steam systems, the insulation that covers pipes, valves, and fittings is often damaged or removed and not replaced. Pipes, valves, and fittings that are not insulated can be safety hazards and sources of heat loss. Removable and reusable insulating pads are available to cover almost any surface. The pads are made of a noncombustible inside cover, insulation material, and a noncombustible outside cover that resists tears and abrasion. Material used in the pads resists oil and water and has been designed for temperatures up to 1,600°F. Wire laced through grommets or straps with buckles hold the pads in place.

APPLICATIONS

Reusable insulating pads are commonly used in facilities for insulating flanges, valves, expansion joints, heat exchangers, pumps, turbines, tanks, and other irregular surfaces. The pads are flexible and vibration-resistant and can be used with equipment that is horizontally or vertically mounted or that is difficult to access. Any high-temperature piping or equipment should be insulated to reduce heat loss, reduce emissions, and improve safety. As a general rule, any surface that reaches temperatures greater than 120° should be insulated to protect personnel. Insulating pads can be easily removed for periodic inspection or maintenance, and replaced as needed. Insulating pads can also contain built-in acoustical barriers to help control noise.

ENERGY SAVINGS

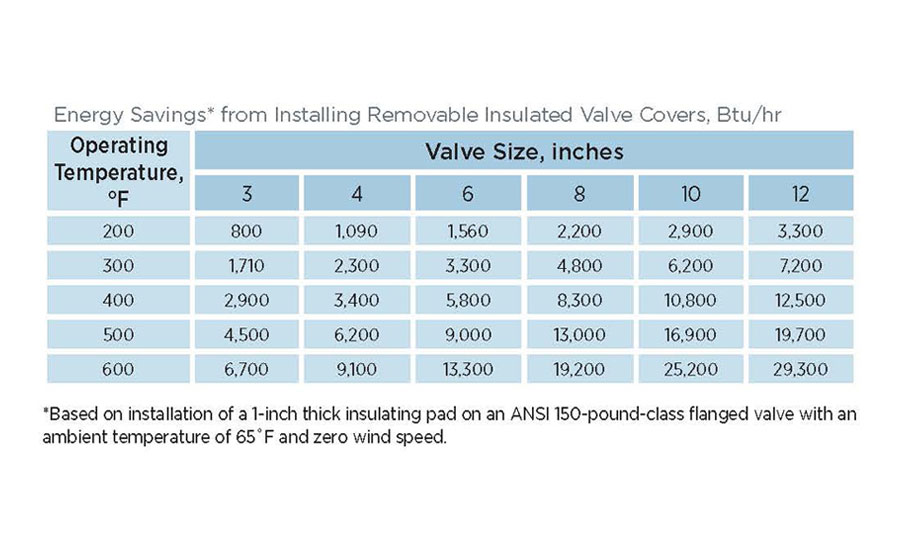

Table 1 above summarizes energy savings due to the use of insulating valve covers for a range of valve sizes and operating temperatures. These values were calculated using a computer program that meets the requirements of ASTM C 680 - Heat Loss and Surface Temperature Calculations. Energy savings is defined as the difference in heat loss between the uninsulated valve and the insulated valve operating at the same temperature.

Example:

Interpolating from Table 1, calculate the annual fuel and dollar savings from installing a 1-inch thick insulating pad on an uninsulated 6-inch gate valve in a 250 pound-per-square-inch-gauge (psig) saturated steam line (406°). Assume continuous operation with natural gas at a boiler efficiency of 80 percent and a fuel price of $8.00 per million Btu ($8.00/MMBtu).

Results:

Annual Fuel Savings = 5,992 Btuh x 8,760 hr/yr/ (0.80 x 106 Btu/MMBtu) = 65.6 MMBtu

Annual Dollar Savings = 65.6 MMBtu/yr x $8.00/MMBtu = $525 per 6-inch gate valve

AVAILABILITY

Insulation supply companies are located regionally; this expedites delivery and helps meet site-specific job requirements. Most supply companies can take measurements on-site to ensure the best fit on irregular surfaces. For customized applications, manufacturers can provide instructions regarding the installation and removal of insulating pads.

NOISE CONTROL BENEFITS

Specify insulating pads that contain built-in barriers for noise control.

INSULATION FOR STEAM TRAPS

Effectively insulate inverted bucket traps with removable and reusable snap-on insulation. Thermostatic traps and disk traps should be insulated according to manufacturers’ specifications to ensure proper operation.

Before removal of all or any existing insulation material, check for asbestos in accordance with Occupational Safety and Health Administration (OSHA) regulations.

SUGGESTED ACTIONS

• Conduct a survey of the steam distribution system to identify locations where removable and reusable insulation covers can be used.

• Use removable insulation on components requiring periodic inspections or repair.

Reprinted from the U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, Steam Tip Sheet #17.

Publication date: 9/19/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment