|

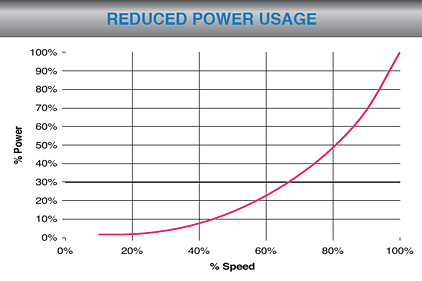

| Figure 1. The chart shows energy savings achieved by Refrigeration Service Co. with use of a variable-speed controller. |

EDITOR’S NOTE: This material was prepared by Heatcraft Worldwide Refrigeration.

Warm summers and harsh winters have long been a hallmark of the northeastern United States, with wide-ranging temperature swings affecting everything from transportation to outdoor equipment performance. Commercial refrigeration equipment is no exception, with warm summer temperatures giving way to the cold, wet winter months, creating the potential to wreak havoc on consistent equipment performance. When commercial refrigeration equipment performance issues arise in the Williamsport, Pa., area, businesses often call Refrigeration Service Co. for assistance.

The company was founded in 1972 and is a family-owned business dedicated to the design, layout, installation, service, and maintenance of commercial, supermarket, and industrial refrigeration, as well as HVAC systems. The company is owned and operated by John Dieffenbach III, along with six service technicians, who provide 24/7 service. They have worked with Heatcraft Worldwide Refrigeration.

An Opportunity to Differentiate

The company was approached by Heatcraft concerning use of the proprietary Heatcraft Orbus variable-speed controller for electronically commutated (EC) motors. Not long after the first few installations, Dieffenbach and his team began to realize the benefits associated with the controller, such as appreciable energy-efficiency gains.

Solution to Cold Weather Starts

Along with motor efficiency, the controller provides improvement in stable head pressure and liquid temperature. In cold-weather climates, like Williamsport, the controller was reported to eliminate the struggles seen with starting and operating condensing units with some traditional head pressure valves during the winter months.

Said Dieffenbach, “In order to get a system up and running properly in cold weather, you need to bypass the low-pressure switch with a delay timer for about two minutes, potentially causing residual damage to the unit, especially the compressor. Using the Heatcraft Orbus variable-speed controller allows us to skip this step, and start the unit right up even in extremely cold weather. Additionally, charging the unit with refrigerant in the summertime is simplified by eliminating the need to calculate additional winter refrigerant requirements ahead of the season.” The ability to eliminate the need for this calculation allows Dieffenbach to be confident the refrigerant charge is correct, whether completed on a 100°F or a -10° day.

Putting Money in Their Customers’ Pockets

Refrigeration Service Co. customers appreciate the energy savings (Figure 1) achieved due to reduced power, said Dieffenbach. Using the controller results in approximately 16 percent energy-efficiency gains, coming from the fan motor and compressor.

Report Abusive Comment