An improperly selected and applied piece of equipment can be rendered completely ineffective if the application itself is not properly defined right at the beginning. It is imperative to address each and every item listed in the following section.

DEFINE THE APPLICATION

• What is the application and what is the fan supposed to do?• How many systems are there and are they interdependent?

• How many fans per system?

• Where is the fan equipment located (inside, outside, next to an office, on the ground or several stories up in a building)? If outside, what are the ambient conditions?

• What space limitations exist? Is there adequate space for maintenance and removal of parts?

• What facility limitations exist in the form of weight, electrical capability, noise, or vibration?

• What fan orientation is best suited for the application?

• What fan arrangement is best suited for the application?

• Are there any leakage requirements for the fan or ductwork?

• Are there any sound limitations including casing radiated or duct breakout noise?

• Are there any storage requirements? If so, how long and under what conditions?

• What are the cost of electricity and any support functions required?

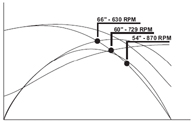

Figure 1. System duty cycle.

PERFORMANCE AND SYSTEM DUTY CYCLE

In order to analyze and make fan and control selections it is necessary to define the system duty cycle. All of the design and operating points must be defined and how long the system operates at each point. This should include present as well as future ratings.The following information for each operating point is necessary:

• Volume flow rate;

• Inlet and outlet static pressures;

• Temperature: design, operating, and rate of change;

• Gas composition if other than air;

• Gas contaminants taking into account erosion and corrosion;

• Elevation and barometric pressure or gas density;

• Single fan, series or parallel operation;

• Method of control.

It is also necessary to create a system duty cycle plot if several performance points are given. That is, plot all operating points on a single graph at a common density. By overlaying the fan performance curve information, it is easy to evaluate the basic fan selection along with the control characteristics. All operating points in the system duty cycle must fall within the fan’s performance envelope. If any operating points fall outside of the envelope, those points will not be realized. This concept is illustrated in Figure 1.

LIFE CYCLE CONSIDERATIONS

The overall effectiveness of the fan/system selection should be evaluated taking each of the following into account:• Initial cost - What is the purchase price and cost of installation?

• Operating cost - What is the total cost per year to operate the fan, accessories, and any support equipment?

• Maintenance - Is maintenance costly and frequent? And, is the equipment accessible for ease of maintenance?

• Frequency of repair and downtime - What is the reliability of the equipment and the cost of downtime?

• Spare parts - Are spare parts expensive and readily available? Must an inventory of spare parts be maintained?

• System availability - What percentage of time must the system be operable? There may be the requirement to have a "standby fan."

• Expected life - What is the expected life of the equipment before it is to be replaced?

THE BASIC FAN SELECTION

The fan type and its performance characteristics influence the basic fan selection. The fan and system must be compatible both structurally as well as from a performance standpoint. For any one performance point, there are many different fans which will satisfy that rating. However, based upon any one set of priorities such as fan size, efficiency, motor size, etc., there is only one best fan for that application.As an example, for a single operating point of 60,000 cfm at 7.0 inches total pressure at a density of 0.075 lbs/cf (70 degrees), several different fans will satisfy that rating. The possible selections are tabulated in the chart above taking into account impeller size, operating speed, horsepower, relative selling price, and recommended motor size.

Depending upon which priority is chosen with regards to acceptability, the optimum fan selection will change. Based upon selling price the 48 inch axial fan would be selected. Based upon operating costs, the 48 inch axial or the 60 inch backwardly inclined fan could be selected. If there was dust in the airstream, the radial tipped fan might be selected taking into account erosion. The optimum fan to satisfy the future rating would be the 48 inch axial utilizing a blade angle change since the centrifugals would have to be increased in speed 16 percent with a corresponding horsepower increase of 58 percent. The motor for the 48 inch axial would simply require better initial insulation so as to handle the increased power.

Figure 2. Rating point location.

FAN SELECTION AND RATING POINT LOCATION

A very important concept is the relationship between size and the rating point location on the fan curve. The generic performance curve for the three backwardly curved fans from the chart is shown in Figure 2. This figure illustrates that the relative position of the rating point on the fan curve changes with a change in fan size for a particular rating. As can be seen, the smaller the fan size used to satisfy a rating, the faster it must run and the farther it will be to the right on the fan curve. In general, it will also be less efficient. It will be louder and wear out faster. This concept is important when considering types of control and fan stability when operation is near peak pressure.

Figure 3. Moving the operating point.

FAN CONTROL AND MOVING THE OPERATING POINT

The following is intended to provide an understanding of the interdependence of the fan and its control with how effectively the system’s performance envelope is satisfied. The fan control method is the means by which the fan/system operating point is manipulated in order to change the desired flow/pressure somewhere else in the system. If you change the system resistance, the operating point will move along the fan curve. Fans equipped with an outlet damper, opposed bladed inlet box damper or a system damper are examples. If you change the fan performance capability, the operating point will move along the established system resistance curve. By having the ability to adjust both the system and the fan performance, the operating point can be moved to almost any desired position under the fan curve. This is illustrated in Figure 3. Controls which move the operating point along the system curve include variable inlet vanes, parallel bladed inlet box dampers, blade angle changes on axial fans, and the many techniques used to change fan speed. It is extremely important to know the individual performance characteristics for each type of fan control.FAN CONTROL CRITERIA

Having the ability to move the operating point creates a whole new set of considerations. These range from performance to physical equipment limitations. Most of these considerations are listed below. Depending upon the installation, some are more important than others; however, all should be considered.• Turndown/leakage

• Sensitivity to change/stability/transients

• Repeatability

• Reliability

• Efficiency expected

• Sound considerations

• Structural considerations

• Environmental considerations

• Interface considerations to computer control

SUMMARY

This article has attempted to outline the major considerations which should be included in any fan and control selection. This can act as a form of checklist or reminder for those who are not involved in selecting fans on a regular basis. It does not guarantee a successful application, but it goes a long way in eliminating many of the common problems associated with a lack of information and communication up front in the selection process.Reprinted with permission from Greenheck’s Engineering Update, Volume IV Issue III. For more information, visit www.greenheck.com.

Publication date:06/18/2007

Report Abusive Comment