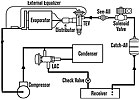

A style of head pressure control valve for low-ambient conditions (Figure 1) has a round pressurized dome at its top that is pressure charged. This valve is often referred to as a low-ambient control (LAC) valve. This dome charge is independent of the refrigerant charge in the actual refrigeration system. The dome charge expands and contracts in volume and acts on an internal diaphragm as the outside ambient temperature changes. This happens because the entire valve is actually located in the condensing unit outside.

FIGURE 1. Head pressure control valve. (Figure

courtesy of Sporlan Division, Parker Hannifin Corp.)

PRESSURE DOME

The expansion and contraction of the pressure charge moves a diaphragm, which in turn moves a piston in the valve and modulates the valve either in a more open or closed position. When the temperature of the condenser is above 70°F, the mixing valve directs the refrigerant flow from the compressor through the condenser and into the receiver. If the outside ambient temperature drops below 70°, the condensing pressure will fall and the pressure of the liquid coming from the condenser will also fall to a point below that of the bellows in the dome of the valve. This causes a piston to move in the valve and partially restrict the flow of refrigerant leaving the condenser.The condenser now partially floods with refrigerant to maintain a certain condensing pressure. At the same time, discharge gas bypasses the condenser and flows directly to the receiver (Figure 1). This superheated discharge gas now mixes with liquid refrigerant coming from the condenser. This keeps the receiver pressure up and helps keep metering devices fed with refrigerant.

These mixing valves will maintain a head pressure of approximately 190 psi for R-502 systems; 240 or 190 psi for R-404A systems, depending on the model of the valve; and approximately 180 psi for R-22 systems at low-ambient conditions.

Dome charges can also be custom ordered to meet specific system requirements. This often allows these head pressure control valves to be used on floating head pressure systems.

FIGURE 2. Refrigeration system with head pressure control

mixing valve used with oversized receiver. (Photo by John Tomczyk,

courtesy Ferris State University.)

WINTER AND SUMMER

The receivers on systems with head pressure control valves must be sized large enough to hold the normal operating charge plus the additional charge needed to totally flood the condenser in wintertime operation. In fact, the receiver should be sized so it’s about 80 percent full when it contains the entire system charge. This allows for a 20 percent vapor head for safety when you are pumping the system down. Any refrigeration system’s receiver should be able to hold all of the system’s refrigerant charge and still have a 25 percent vapor head for safety.A refrigeration system can have a head pressure control-mixing valve used with an oversized receiver (Figure 2). Most manufacturers publish charts and tables on system charge recommendations; this shows the service tech how much refrigerant to add to a system that has a head pressure control valve designed to flood the condenser in colder weather. Most of these can be accessed on the Internet.

If the receivers of a refrigeration or air conditioning system haven’t been oversized to accommodate the extra refrigerant for flooding the condenser during low-ambient conditions, you need to remove refrigerant every spring to prevent high head pressures at design ambient conditions, then add it again in the fall when it will be required for flooding the condenser. This technique is often referred to as a winter-summer charge procedure. Oversizing the receiver can save the customer this added labor charge.

FIGURE 3. Troubleshooting includes feeling the line between

the valve and the receiver. The cold or warmth should provide some guidance. (Figure courtesy of Sporlan Division, Parker Hannifin Corp.)

LOW-AMBIENT TROUBLESHOOTING

Troubleshooting a low-ambient head pressure control valve with a pressurized dome can be pretty easy if you take the proper steps.If the outdoor ambient is below 70° and the head pressure is low, feel the line between the valve and the receiver (Figure 3). If this line is cold, the valve is not allowing the compressor’s discharge gas into the receiver. The valve is defective and should be replaced. This line should be warm at an ambient below 70°. If the head pressure is low, the ambient is above 70°, and the line between the valve and the receiver is hot, the valve is defective and should be replaced.

The line should be a little warmer than the ambient because of the subcooled liquid coming from the condenser’s outlet to the receiver at the warmer outside ambient. Discharge gas flow from the receiver should be shut off by the valve. However, the system could also be low on charge, causing a low condensing pressure and fooling the valve. So, don’t replace the defective valve until after you verify that the system charge is correct.

To replace a defective low-ambient control valve with a pressurized dome charge, follow these steps:

1.Recover refrigerant.

2.Cut the process tube on the valve’s charged dome to remove the pressure charge.

3.Using a torch, heat the valve until the solder solidifies and remove the valve.

4.Wrap the valve’s body with a heat sink to prevent damage; silver solder a new valve in place.

5.Install a new filter-drier.

6.Leak check the system and evacuate to a deep vacuum (500 microns).

7.Charge the system and leak check again.

Publication date:06/04/2007

Report Abusive Comment