Home » Keywords: » sheet metal training

Items Tagged with 'sheet metal training'

ARTICLES

SMART Heroes allows veterans and active-duty service members to spend seven weeks at one of the program's two military installations

Read More

Troubleshooting Foil Tape Challenges: Common Issues for HVAC Installers and How to Solve Them

Foil tapes play an important part in ductwork and HVAC efficiency

Read More

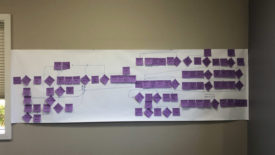

How Process Mapping Can Elevate Your Prefab Strategy

Lifelong professionals don’t often commit their tips, tricks and trade secrets to paper, which is why you need to ‘map your processes’

Read More

Pennsylvania Man Takes National Role in Sheet Metal Education

Wilson began career in D.C. area, now works with union training centers

Read More

Pittsburgh Sheet Metal Training Coordinator Named Program Administrator for National Fund

Liebert has earned the respect of his colleagues at the ITI, who laud his devotion to family and teamwork

Read More

SMOHIT Recognizes Safety Leaders in the Sheet Metal Industry

Group recognizes Christiansen Heating and Sheet Metal, CMC Sheet Metal, R.F. Knox Company/Georgia Sheet Metal JATC, Superior Duct Fabrication and Nortex Roofing

Read More

ITI's 2023 Coordinators Conference Offers Recruitment, Retention Resources

From recruitment and retention and grants to curriculum, standards and handbooks, the conference offered coordinators various ways to retain talent

Read More

How to Care for Snips

Oil the pivot bolt, avoid sprung blades and fully closed jaw cuts to maximize the life of snips

Read More

Why Purchasing a Roll Forming Line with Material Handling Increases Efficiency, Safety

Front end decoilers certainly can help speed up operations and various end-of-the-line material handling options are also available

Read More

What to Expect at the METALCON Metal Training Zone

Contractors can get hands-on metal roofing experience with Sheridan metal tools and more

August 24, 2023

Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1699608318&width=275)