Several respondents to the survey commented that the only way things will begin to change is if HVAC contractors educate building owners and general contractors regarding the problems associated with starting up HVAC equipment before a project is finished.

The Sheet Metal and Air Conditioning Contractors' National Association (SMACNA) plans to supply the necessary ammunition contractors and engineers can use in the fight against general contractors and building owners who insist on starting up HVAC equipment while a project is under construction. SMACNA is currently in the process of creating a white paper on the topic, a document that participants in The News' online survey believe is sorely needed.

"I think it's great that you are addressing this issue," stated Peter Dutile of Dutile Refrigeration Co., Laconia, N.H. "It has to be the most interesting subject I've seen in a long time, and I've been doing this for 30 years."

When asked how often general contractors or building owners ask to provide early startup of HVAC systems, 88 percent of the survey respondents answered "all the time" or "sometimes." A handful of respondents (11 percent) replied that they were asked to provide early startup "only on rare occasions." Only 1 percent answered "never." (See Figure 1.)

"This is a very sore subject with GCs [general contractors] and me," wrote Dutile. "I am never able to overcome a customer that ‘is holding the checkbook' and insist that permanent heat is never to be used as temporary heat."

He concluded, "I would love to see a publication that I could give to customers that outlines the dangers of using the permanent system for temporary heating/cooling."

Differing Viewpoints

Matthew Smith understands that sentiment. The owner of Smith Heating & Air Conditioning Inc., Stockton, Calif., was at a project last year, trying to inform an owner and a general contractor that there was danger in starting up the HVAC system during construction. The two parties stopped him short."They basically asked the question, ‘Where do you come up with this opinion? We have never seen anything in writing that discusses the concerns of an early startup of equipment. Show us an authority. Show us something who can back up what you say because what we see is an uncooperative sub.'"

Thanks, in part, to this conversation, Smith and SMACNA are looking to produce a white paper on this exact subject. Smith, chairman of the HVAC Contractors Council Steering Committee, introduced this issue at the 2004 SMACNA convention in Hawaii. It received plenty of reaction and concerned comments from the members sitting in the session.

When The News asked if this was a problem in the industry, it was swarmed with responses.

"Working in Idaho during the winter, every contractor not only wants but requires early startup of equipment, not to enable cabinets to dry, but to at least raise the temperature to above subzero," wrote Cathy Kneeland of Alpha Mechanical, Idaho Falls, Idaho. "It is expected that we either provide temporary furnaces or allow our equipment to be fired off. Issues in doing this are many and include warranty start date, debris in the system, labor costs for multiple trips, manufacturers' refusal in honoring warranties, and even homeowner complaints that now the system ‘smells like construction.'

"Hopefully, you will hear from more of us in the North and we can get more insight on how they provide heat without compromising themselves or the new equipment."

When asked if their company has a standard form that includes a disclaimer for early startup, 75 percent answered no. (See Figure 2.)

Shame on you if you do not have such a disclaimer, wrote Richard Brown of Lyons Service Co., Bowling Green, Ky.

"Early startup should be expected," stated Brown. "If the equipment is in place and operational, it only makes sense to go ahead and start using it. We agree to perform early startup, provided the customer or general contractor enters into a scheduled preventive maintenance agreement. We ex-plain to the customer that once the system is started, it requires scheduled maintenance, or otherwise all warranties are void.

"Handling the early startup in this fashion not only takes care of the equipment, but also results in converting the early startup preventive maintenance into an annual preventive maintenance agreement directly with the owner once the building is occupied."

Bill Stribling of Sullivan Service Co., Birmingham, Ala., was more philosophical.

"While I agree we should have a position on the topic, shouldn't that opinion explore the valid concerns of the contractors, other subs, and the homeowner?" he questioned. "What value will the homeowner place on a pristine A/C system if the floors warp or the paint won't stick to the walls? Houses aren't built in a vacuum, and we must acknowledge we are but a piece of the project.

"Maybe the question should be, ‘How can we work with our contractors to help deliver the house in working order?' - not just the HVAC system. I suggest we provide (at a cost) portable dehumidifiers, heaters, spot coolers, and other temporary conditioning devices during the construction."

It Starts When It Starts

Many contractors who filled outThe News'survey were not sure about the warranty implications of early startup. When asked if their HVAC supplier could void warranties for early startup, 45 percent of respondents answered, "I don't know." (See Figure 3.)Dave Singer, senior commercial service representative from Carrier Great Lakes, Detroit, gave his perspective on the subject.

"The warranty begins when the unit is placed, piped, wired, and started," wrote Singer. "The warranty covers all parts for one year from date of startup. The warranty doesn't start when the ‘owner accepts it,' which is usually when the project is complete. Some projects can take a long time to be accepted as ‘complete.' Does this mean the warranty is actually two years? No. Unfortunately, this is not the case. If a rooftop unit is started for temporary heat, the warranty starts. This is only fair, isn't it?"

Singer did pass along some suggestions.

"If a general contractor's project requires temporary heat or cooling, the cost for such should be figured into his costs, not the HVAC/mechanical. You see, when it comes down to money, the mindset is to go after the guy with the deepest pockets. Belly up to the bar and be accountable for your own needs or requirements. The contractor should review his bid documents. These should be clear. Do the documents address temporary heat or cooling or even ventilation? Does the owner understand the manufacturer's warranty?"

As most will attest, Singer noted that problems can crop up long after the project is finished.

"The other unfortunate thing about this is that the issue doesn't even come to light until long after the job trailers have been plucked from the site and the job is closed out as far as the general contractor or project manager are concerned," wrote Singer.

"From my vantage point, the issue doesn't even come up until there is a warranty - or should I say out of warranty - concern. It is then that the finger is pointed at the manufacturer and, in the end, it is the loyal contractor who ends up getting burned."

He summed up the current "rules of engagement" this way: "The one with the checkbook is the dictator. If you don't like his rules, someone else who is willing to gamble gets the job."

A Complex Issue

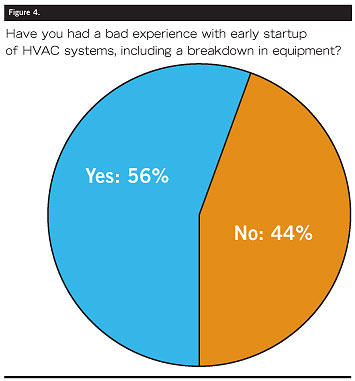

When asked if an early startup had resulted in a breakdown in equipment, 56 percent of respondents answered yes. (See Figure 4.), but based on their comments, the costs associated with an early startup problem can vary. When asked what sort of additional costs were imposed by early startup problems, 56 percent of the respondents checked the "under $1,000" choice, while 25 percent checked "no additional cost." However, 15 percent of respondents pegged the cost at between $1,000 and $9,999, and 3 percent said cost exceeded $10,000."We put a clause on all of our scopes that states that startup is to be done no more than 90 days before substantial completion," stated Baya Pruitt of Conditioned Air Systems Inc., Gainesville, Ga. "If more time is required, then it will cost additional money for extended labor and material warranties."

Based on the survey, it appears most contractors (60 percent) know when an early startup is planned. However, when asked if the early startup is usually due to a crisis situation, 44 percent of respondents said yes.

"It seems like every time a builder needs a startup, it's always on a Friday at 4 p.m. and it's always a big deal to the point that we may lose their business if we don't do it right then," wrote Lee Chapman, Comfort Technology Inc., Hampton, Va.

"Older framers and drywallers are the worst," said Andy Sommer of Sommer Heating & Cooling Inc., Tell City, Ind. "They want the heat on as soon as possible to stay warm and to keep the drywall mud from freezing."

Emil Friberg, P.E., of Friberg Associates Inc., Fort Worth, Texas, summed it up this way:

"I agree that there needs to be an industry position on this subject, but I believe that it should focus on the recommended procedures and methods of allocating cost rather than prohibiting operation during construction," he said. "It is a complex subject."

Sidebar: How Some Contractors Handle The Situation

Along with horror stories and complaints, many contractors provided explanations and procedures as to how to handle early startup requests. Here are just a few:"After reading your article, I sat back and laughed. How many times have I kicked myself for letting my service department go ahead with the early startup? Being in the A/C business for over 16 years, you would think I would have learned by now to just say no. Well, I have started doing just that and it works if presented properly and with the general contractor in mind. The horror stories are endless. I have lived in southwest Florida my entire life, and I am amazed at what humidity and tropical conditions can do to a home. Early startups have always been a must in this part of the country due to these conditions. I am all for a new industry standard that addresses these growing issues."

Jason Schreyer

Sunset Air Inc.

Ft. Myers, Fla.

"In our large custom homes construction division, we are routinely asked to provide A/C during construction to temper the space and dehumidify the woodwork. We have a form that the contractor must sign if this is to happen with permanent equipment, which is rare now, as we have come up with a solution that saves the permanent equipment but provides A/C at the critical time in the construction process. In about 75 percent of these jobs, we provide, for additional fees, temporary air systems with package units and flex duct. We also sell a filter change on a weekly or daily basis, depending on the contractor. We end up selling the package unit to the contractor and when the job is through, we take care of the cleanup and removal. I can tell you that the package unit is pretty well used up with drywall and tile grout dust impacted throughout the coils."

W. Theodore Etzel III

Conditioned Air Corporation of Naples

Naples, Fla.

"On our standard company proposal form, we state that a maximum of 90 days run time will be provided for HVAC equipment. We start the discussions early and inform general contractors that the building must be kept clean and sections isolated if near areas are still under construction. We know that some conditioning of the air is required to do the finishes in every project - thus the 90 days maximum. We will include in our estimate extra filter costs, including labor. We will shut the system down if building cleanliness is not maintained, but as in your article, this is tough since the man writing the check likes to keep control. Nothing is started on temporary power, water, or gas."

Kenny Gee

Conditioned Air Systems Inc.

Gainesville, Ga.

"Architects and engineers should always write into specs that the building systems will not be used for temporary heat, cooling, or ventilation. The stupidity of general contractors never fails to amaze me when it comes to HVAC systems and early startups. ... As an industry, we need to hold general contractors accountable for this practice and we all need to require a disclaimer be signed by the owner and the general contractor prior to doing an early startup."

James Maidlow

Lehman's Mechanical

Anderson, Ind.

Sidebar: Oh, The Horror Stories Contractors Can Tell

Those who answeredThe News'recent online survey regarding early startup of HVAC equipment were not afraid to relay some of the sad-but-true results of turning on the switch before a project is complete. Here are a just a few examples:"As a 28-year veteran of Research Products and the Space Gard and Aprilaire high-efficiency air cleaners, I choke every time I enter a new home project under construction with one of our air cleaners installed on a very expensive high-efficiency system, only to find the installer placed the 201, 401, or 501 media behind the furnace still in the carton. The installer has then installed a 1-inch throwaway filter inside the air cleaner cabinet. The reason provided is that they did not want to add to the expense of getting the $15 filter media dirty during construction.

"Meanwhile, the blower wheel and the evap coil then become the secondary filter, rewarding the new homeowner a very questionable system when they move in."

Jim Kramer

Light commercial territory manager

Research Products Corp.

"Every general contractor wants the equipment started before the finishes are done. That saves them the expense of renting temporary equipment. They also don't care who has to go back and clean out the units. After drywall dusts gets on a damp coil and hardens, you may as well change out the coil. Also, I have changed out control boards that burn out due to temporary use (due to dust, low voltage, improper wiring, etc.)."

Daniel Vance

Command Heating Inc.

Grove City, Ohio

"When we tried to explain to the customer that the early startup could void the warranty, they asked what kind of cheap equipment did they buy. They had been talking to a taper, who is the one who did not provide his own construction heat and would have had to pull off the job if he didn't get some. It is a very touchy situation every time it comes up."

Lynette Gefroh

Prairie Heating & Air Inc.

Linton, N.D.

"I am referring to my past experience with a contractor 20 years ago as a service manager. We were always expected to provide the heating and/or cooling while the home was being completed. By the time the homeowner moved in, their furnace looked like it was 10 years old."

Joe Ramunni

Arzel Zoning Technology

Cleveland, Ohio

"Builders in the area subcontract a large amount of interior rock work and artistic log construction to fit the needs of their clients and the area culture of Salmon, Idaho. While we, as HVACR techs and service providers, are accustomed to working in uncomfortable atmospheres, the eclectic journeyman artists of this area prefer working where it is comfortable. Consequently, we are pressured to install, start, and hopefully test systems in buildings that are not ready for steady-state operation. And, we take the heat when systems don't operate as advertised when running under extremely adverse conditions (as designed for the finished building)."

Paul Smith

Service Refrigeration

Salmon, Idaho

"Electricians are allowed to do a ‘crank up' on commercial equipment so the other trades can work in comfort and drywall mud can dry out, etc. Then the A/C guy comes and does a final startup on the equipment to find it full of construction dust.

"In regard to residential applications, blown wall insulation is in the air from construction, and when the equipment is started (early or otherwise), it sends tiny black particles through the air filter. This is only evident on houses with white carpets, as it leaves a black stain under the bedroom doors. New homeowners without white carpets are un-knowingly breathing these fine particles."

Steve Wiggins

Quality Air Care

Lorena, Texas

"We had a job with an indoor pool, whose space was conditioned by a Dryotron unit. The homeowner insisted that the pool be filled before construction was completed so her children could use it for a party. Despite our concerns, the homeowner would not budge. We had her sign a form saying the startup was done against our wishes and the manufacturer's guidelines. The coils ended up loaded with sheetrock dust, which is just about impossible to remove from a six-row coil. We have had airflow problems ever since. Although we do not have a standard form for this type of situation, having her sign off on our concerns probably saved us from a very expensive repair."

Mickey Kiernan

Comfort Specialists

Oceanside, N.Y.

"One project that I recall was an indoor air handling unit. The contractor called and advised the dual fan assembly was knocked off its isolators and the fan wall was buckled, along with the unit housing. On reviewing the installation, it was put in temporary startup use in order to dry out the plastering during the construction. Following this, a number of mishaps took place. First off, the roughing filters put in place were plugged with plaster and construction dust. Amazingly enough, none were pulled through. When asked about change-outs, the contractor honestly said, ‘If I change the filters when they get dirty, I would be changing them every few hours. It's just not practical.'"

Barry Lampel

York, Pa.

Sidebar: ASHRAE May Address Issue, Too

After reading about SMACNA's plans inThe News("SMACNA Plans To Address Early Startup," page 1, Nov. 29, 2004), Bruce Lindsay, P.E., informedThe Newsof his intention to urge ASHRAE to address this issue, too."I am currently serving on ASHRAE technical committee (TC) 7.8, Owning and Operating Costs," wrote Lindsay, who doubles as director of business development for Temp-Air, Burnsville, Minn. "At the upcoming TC meeting in Orlando on Feb. 7, I will be attempting to obtain approval to conduct a forum at the June [ASHRAE] meeting in Denver on this topic. I hope that enough ASHRAE members would recognize the potential liabilities and recommend that the society issue a position (a long process).

"Further, I am hoping to organize a follow-up seminar on this topic for the January [2006] meeting in Chicago. In the past, I have been able to upgrade two of my technical seminars to the public session. I think this topic would warrant that in Chicago."

In Lindsay's estimation, his understanding regarding early startup is, as he put it, "straightforward."

"Unless the design engineer has addressed the operation of the HVAC equipment during construction within his design intent statement, it must be assumed that he/she does not want it to be operated and that he/she has not made provisions in the HVAC system for its operation before the facility is completed. Any liabilities resulting from operation of the permanent HVAC system during construction shall not be borne by the design engineer."

To reach Lindsay, e-mail him at blindsay@temp-air.com.

Publication date: 01/24/2005

Report Abusive Comment