It was a very hot August day when Bob received a call from the dispatcher telling him that an office building was not cooling properly and needed to be checked. This is a new customer for the company. The system is about seven years old.

Bob arrives at the office and goes to the lady who manages the building and handles all mechanical calls. She says, "The building is not holding the temperature conditions that it normally does. It also feels very humid. It started yesterday and now it is noon today and it's still uncomfortable."

Bob asks to see how she knew what the building temperature is and she showed him a quality thermometer that she uses to take around the building when there are temperature complaints. Bob says, "You really look out for the building and that's good."

The manager then leads Bob to the equipment room where the air handler is located and leaves him to investigate the problem himself.

About this time, Btu Buddy appears and says, "What is the matter Bob?"

Bob explains what he knows, that the system shows all signs of cooling except it is not holding the building temperature as it normally does.

Btu Buddy suggests, "Put your gauges on the system and I think you will find the answer."

Bob fastens gauges to the system and asks Btu Buddy, "Why is the suction pressure so high? I would expect it to be about 70 psig because the refrigerant is R-22. But look at this; it is 79 psig. The suction line is so cold that you can hardly hold it."

Btu Buddy says, "Get your temperature tester and see what the superheat is at the compressor."

Bob fastens a temperature lead to the suction line and says, "The superheat is 0. The suction pressure is 79 psig which means the refrigerant is boiling at 47 degrees and the suction line is reading 47 degrees. Refrigerant is flooding back to the compressor but it is not knocking or making any excess noise like I thought it should."

Btu Buddy says, "Find out why it is flooding back and cure the problem, then we will discuss what you found. Let's protect the compressor first. What would be a good reason for it to flood back?"

Bob says, "The expansion valve is not controlling like it should. I will take a look at it."

Checking The Expansion Valve

Bob goes to the equipment room to investigate the expansion valve. It shows no signs of anyone removing the cover to the expansion valve adjustment, so he starts looking at how the expansion valve bulb was mounted and finds that it had been mounted on the suction line using nylon tie-wraps and they were both broken from age. The bulb was very loosely insulated.Btu Buddy says, "Shut the king valve at the condenser and pump the system down into the condenser while you make the repair to prevent any more flooding of the compressor."

Bob pumps the system down into the condenser and asks, "Now what?"

Btu Buddy explains, "Now is the time for an explanation of how an expansion valve bulb should be mounted. The object of mounting the expansion valve bulb correctly is to accurately measure the temperature of the vapor in the suction line. There are five factors that enter into locating the bulb:

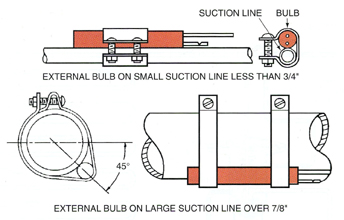

2.The bulb should be mounted at different places on the circumference of the line depending on the line size. On a small line, it should be mounted on top. The larger the line, the closer to the bottom it should be mounted, but never on the bottom because, as you know, oil is circulating also and can act as an insulator. Oil will travel on the bottom of the cold suction line.

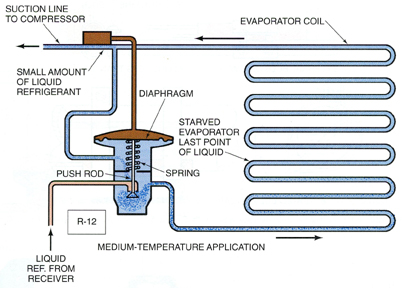

3. The bulb should be located before the connection for the external equalizer line because, if the valve had an internal leak, it would give a false reading and starve the evaporator coil of refrigerant (Figure 2).

4. It should be firmly mounted on the correct position on the line (Figure 3).

5. The bulb and line should be well insulated with no air passing over the bulb.

If any of these steps are omitted, good control of the superheat may not be possible. Which of these five items has been violated?"

Btu Buddy explains, "This has been an advancing problem. First, one of the straps failed and the system was beginning to lose control. Then the second strap failed and pushed the bulb insulation up so that air that is blowing out of the side of the air handler where the suction line goes through the cabinet began to blow under the insulation, and the bulb lost control. It has probably not done damage, but it must be repaired now or damage to the compressor will occur."

Bob asks, "Why was the system not cooling and dehumidifying? The coil sure was cold."

Btu Buddy explains, "The design temperature for this coil would typically be 40 degrees and it was operating at 47 degrees. This would raise the outlet air temperature by 7 degrees and would reduce the moisture removal ability because of the coil temperature rise."

By this time, Bob has fastened the bulb down on the line correctly using two copper straps and has insulated it correctly and tightly where air cannot pass over the bulb. It is now time to start the system again.

The system is started and, as it runs, the suction line warms up to about 14 degrees of superheat at the compressor. The compressor stops sweating and the suction pressure lowers to 72 psig and is still coming down.

"Now," Bob asks, "why wasn't the compressor making a noise?"

Btu Buddy responds, "The refrigerant returning to the compressor was what we call ‘wet vapor' with a small amount of liquid in it. It has 0 degrees superheat, but not enough liquid to reach the compressor cylinders. The liquid was boiled to a vapor in the motor housing and the crankcase of the compressor. The long-term damage that this would cause is reduced lubrication to the compressor. If you can imagine a comparison to your car, if it should use 40-weight oil and you diluted the oil with 50 percent kerosene, the oil would not maintain the oil film between all moving parts. It would not cause immediate damage, but the more you operated it, the more damage it would cause. The reason for pumping the system down was to prevent excess flooding while you were working with the expansion valve bulb and to pump any liquid refrigerant out of the compressor for when we restarted it after the bulb repair."

Bob asks, "Why did the suction line feel so cold? It certainly didn't feel like 47 degrees. It seemed much colder."

Btu Buddy explains, "When there is liquid refrigerant in the line, it will take the heat out of your hand so fast that it seems to hurt your hand. It is still 47 degrees, but the heat is removed faster and it feels colder. Also, your hand heat will not quickly cause the suction line to raise in temperature like it will with vapor only in the line."

The system is now operating correctly and Bob goes to visit the manager and explain the problem and the repair. He talks to the manager about a service contract for the building that would involve regular filter changes, motor lubrications, and performance checks for cooling in the spring and heating in the fall. He gives her a written proposal from his company.

She thanks Bob for a professional job well done.

Riding away, Btu Buddy says, "You have garnered another customer for your company. You are adding to their business and they like that."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Delmar Publishers. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or bmj@myexcel.com.

Publication date: 09/20/2004

Report Abusive Comment