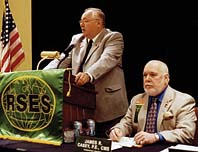

But his talk was more than a slogan. It dealt with understanding why systems work the way they do rather than relying on rules of thumb; and it meant those who service equipment have to have some selling skills.

Bradford noted that as a young man he followed his father on service calls. He said he used to ask his dad why he did servicing the way he did. Even though his father was considered a first-rate technician "and knew what he could do with his hands," he couldn't answer many "why" questions.

So Bradford found himself turning to the training programs of RSES. "RSES answers the ‘why' questions and establishes a good foundation for a technician in the business."

Learning in order to be the best has to extend beyond technical skills and include the bottom line, he said. "Some business sense has to be built in and that includes charging enough to be profitable and stay in business," he said.

"If you don't charge enough, you are not going to be around five years down the road for your customers," Bradford said. "The worst disservice you can do to your customers is not to charge enough. The best advertising is when one of your customers tells a neighbor, ‘They're high, but they are good.'"

Business sense is necessary, he said, especially when "that somebody who might not be as good as you (technically) does not provide the customer with the quality of service you would."

Bradford is pragmatic when it comes to errors. He acknowledged that mistakes can happen, but every effort must be made to avoid errors that could lead to fatalities. Further, he said, technicians need to learn from mistakes and not repeat them.

He recited a personal experience. He once changed out a compressor he thought was defective, only to discover that the voltage from the power source did not match the specifications for the compressor.

Bradford urged contractors to "Let others be the best they can be." He said, "There are a lot of people who need training. Mention RSES and the training it offers rather than criticize."

In fact, Bradford suggested those most wanting training ought to commit to teaching. "If you've never taught a class, get involved with training. If you want to learn a subject, teach it. My pop used to say, ‘If you know how to fix something, you'll always have a job.' But today you've got to know why. If you know the why, you can also teach others."

The Future Of R-22

As an example of how RSES education stresses specifics, Bradford's keynote address on the value of education was immediately followed by a seminar on refrigerants presented by Stephen Spletzer, service applications engineer for Atofina. He gave the audience made up almost entirely of technicians a reality check on R-22, in light of a worldwide phaseout of HCFCs.His basic message was that every effort should be made to have systems currently running on R-22 continue to run on R-22 as long as possible.

"In general, there is no need to move from R-22," he said. He acknowledged a phaseout of R-22 in new equipment by 2010 and a phaseout of the refrigerant for aftermarket servicing by 2020. But he said there are no regulations to prevent the use of R-22 for years beyond that.

Further, he said he did not expect a severe crunch in supplies of R-22, as happened with R-12. He said there are some incidents of end users moving from R-22 at a faster pace, such as in Europe, where use of R-22 in new equipment ended in 2000, and in the bakery industry in the United States, where some leaking issues came under EPA scrutiny and caused that segment of the industry to look at non-HCFC alternatives.

Spletzer did review some of the alternatives to R-22. He pointed to HFC-410A as a strong candidate, mainly because of its ability to deliver a better SEER, which is required by federal mandates in the air conditioning sector. He also noted efforts to make R-410A work in food cases and positive displacement chillers.

Further, Spletzer pointed out that R-410A is not a retrofit refrigerant. For example, he said if a unit designed for R-410A is charged with R-22, it could result in low capacity, no subcooling, compressor noises, poor efficiency, and low pressures.

If an R-22 unit is charged with R-410A, "It may not work at all or may result in early failure. Compressors will fail in record time," he said. He added that R-410A also may not be a good A/C refrigerant when ambient temperatures exceed 125 degrees F.

He noted, "Many major equipment manufacturers have R-410A units for sale." While currently such units only represent about 3 percent to 4 percent of market share, their "presence is ramping up. R-410A is a safe and proven product."

Spletzer also touched on another R-22 alternative, R-407. It has, he said, almost identical vapor pressure as R-22 and slightly higher liquid pressure. But despite the close match, he said, R-407C is losing ground to 410A because of the higher SEER potential of 410A and some glide questions with 407C.

Sidebar: RSES Forges Links With Other Associations

NASHVILLE, Tenn. - The Refrigeration Service Engineers Society (RSES) is entwining itself more closely than ever with other HVACR trade associations and organizations, both to provide its training expertise industrywide and to improve revenue coming to RSES.Executive Vice President Robb Isaacs told delegates at the 66th annual conference about RSES' relationship with the North American Technician Excellence (NATE) program in which RSES provides the training for those planning to take NATE certification exams. Isaacs noted those potential test takers come from inside and outside RSES.

In addition, they are often technicians who work for contractors who are members of such organizations as the Air Conditioning Contractors of America (ACCA), and the Plumbing, Heating, Cooling Contractors -National Association (PHCC). "ACCA and PHCC employ [current and potential] RSES members," Isaacs said. "We need to go to them to supply training."

The RSES push to bring education and training to a broad spectrum of the industry has an additional pragmatic purpose as the society battles some recent deficit budgets.

Isaacs pointed out that another issue the society faces relates to survey statistics that show only 8.5 percent of its members are 25 years old or less.

"This is a problem we have to address. We are working with schools, RSES chapters, and others to address it." At the same time, he did note that one factor that may be playing into the under-25 issue is that more and more people in the 35 to 42 age range are entering the HVACR industry for the first time after having been in other trades. But, he said, that still doesn't negate the fact that "The youth are not coming into the industry."

Refrigeration Certification

He noted RSES is putting together a nine-month training program in refrigeration, which is designed, in part, to set the stage for a possible refrigeration certification program. He noted a number of manufacturers have voiced support for such a program, in part because of problems they are having with returned equipment that end up not being defective.

"But they can't do anything, because there is no refrigeration certification," Isaacs said. The program, to be funded, he said, by manufacturers, consists of such general areas as walk-ins, reach-ins, defrost, and subcooling down to specific subcategories.

Also At The Conference

In another announcement, Issacs noted a new relationship with Goodman Manufacturing for RSES training programs.

During the open business meeting, it was reported that membership as of Sept. 24, 2003 was 15,743, a drop of about 725 members from the previous year.

During an awards luncheon the day before, Harlan ‘Skip' Krepcik, a member of the Tidewater Chapter in Norfolk, Va., was named Member of the Year, an annual award that first was given in 1959. Speaker of the Year honors went to William Sammons of the Greater Cincinnati Chapter.

The officers of RSES elected by delegates are International President Streeter Turner, Vice President Kenneth Bachner, Treasurer Ronald McCarthy, Secretary Jerry Richey, Sergeant-At-Arms Harry "Butch" McGuire, and Educational and Examining Board Chair Loren "Shorty" Shuck.

The society also announced that its next annual conference will be Sept. 30-Oct. 2, 2004 in Calgary, Alberta.

- Peter Powell

Publication date: 12/22/2003

Report Abusive Comment