With the recent surge of interest in IAQ options like high-efficiency filters, air cleaners, UV-C lights, and humidifiers, consumers might easily forget that those components must still work within a system.

In many such scenarios, if a motor and drive aren’t operating, then the air isn’t moving. If the air isn’t moving, then that IAQ equipment can’t perform. And when that equipment is not performing, then the design benefit disappears and the investment is not paying off.

That is the entire, surprisingly short journey from “what does a motor have to do with my IAQ and health” to “well, of course, an efficient motor and modern drive are essential for this system to do what I want.”

Indoor Air Quality Needs, Home or Away

Mark Pierce, vice president of sales and marketing for ebm-papst, said that while air purification has been a trend in the sights of manufacturers making air handling products for more than a decade, IAQ “has taken on a whole new relevance in 2020. The interest in IAQ has increased dramatically.”

More of the general public has adopted a level of concern that was previously more predominant among those with allergies or asthma.

Ebm-papst started making high-efficiency fans in the 1970s, Pierce said, and today’s technology now brings the advantages of electronically commutated motors (ECMs) from it and other companies.

Residential interest may be driving much of the recent uptick, and interest is up for office spaces as well, but other areas like health care are no stranger to the necessities and benefits of efficient motors running most or all of the time.

Mark Hansen, vice president sales, HVAC/R – USA for Danfoss, noted the market for his company’s drives has long included “critical applications such as isolation wards in hospitals, where negative room pressure aids in preventing contaminants infiltrating the rest of the facility via the HVACR system.”

Pierce added that ebm-papst has worked in this space thanks in part to the “medical sector’s requirement for more freestanding, commercial-grade air purifiers” for patient safety.

Meeting HEPA Needs

Regardless of system particulars, HEPA filters in particular rely on effective motor/drive support.

“These applications require the proper air mover that will handle the increased static pressure these filters cause in the airstream,” explained Pierce.

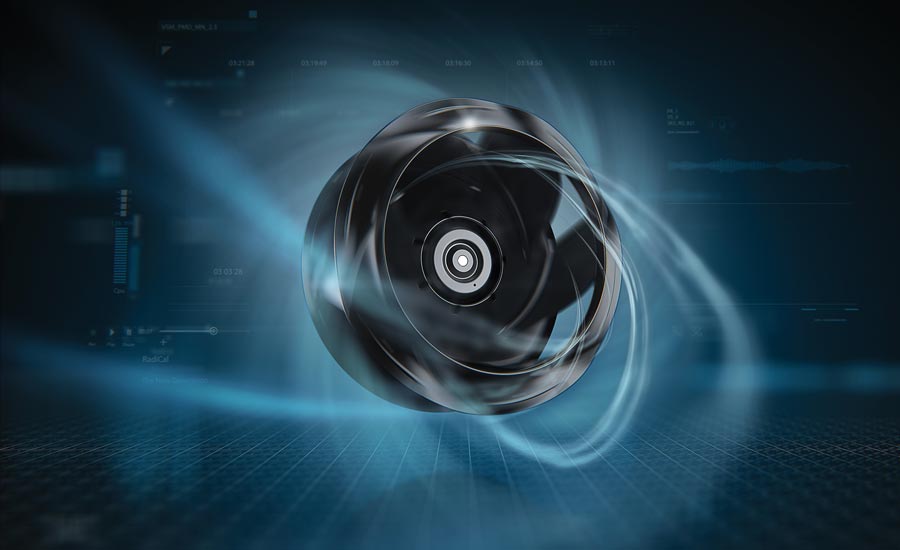

In ebm-papst’s lineup, ECMs in conjunction with either air foil or patented RadiCal© impellers are designed to do that job of maintaining airflow while maintaining low power consumption.

Hansen continued the line of thinking, noting that increasing fan speed intelligently can compensate for those gradually clogged filters.

“When it comes to VFDs as part of this design effort,” he said, “the VFD is still underutilized.”

RADIAL DETAILS: Recent material from ebm-papst explains that a radial fan design — allowing air to leave the fan at a right angle to the inlet — not only provides efficiency but makes backwards curved impeller fans like RadiCal units a good choice for the conditions created by HEPA filter systems.

Beyond the reliability inherently required to deliver the intended effect, Hansen listed a few aspects of VFD technology that can go underused in commercial settings:

Redundant drive bypass capability (with an auxiliary drive) provides backup and seamless changeover as necessary.

PID loop control can serve as backup, too.

“If your BMS operation is interrupted, you want your VFD to take control locally of the application,” he said.

Pre-engineered VFD/sensor packaging or sensorless field-programmable software both offer advantages over older options. Hansen also highlighted “VFD/motor modeling (i.e., matching the motor characteristics for the VFD) for maximum performance.”

Finally, HVAC service and maintenance is getting more predictive across the board, and Danfoss furthers the trend in this area with condition-based monitoring, described as “preventive measures to predict premature failure.”

Selling The Point

All that might make sense, but it still isn’t obvious to every consumer (or contractor, necessarily) that might appreciate the opportunities. How can the point get across?

Morgan Silvey, director of marketing, HVACR aftermarket, for motor manufacturer Nidec, shared how his team approaches this subject.

“Nidec mainly brings attention to the dramatic energy savings and the comfort improvement because of slower air moving when the system is not heating or cooling,” which also serves to reduce the sense of drafts.

Silvey reported that Nidec is upping its promo efforts behind its IAQ products, with its distributors adding communications like streaming video loops, virtual meetings/trainings, and literature pieces for contractors.

Moreover, he said, Nidec is developing a website feature for the fall that “displays efficiency and local utility savings” offered to a given customer by one of Nidec’s latest offerings.

A brochure from the manufacturer included a tagline to sum up the relationship: “If your homeowner’s fan motor isn’t running continuously, their IAQ equipment isn’t, either.”

In its own recent two-page paper on IAQ importance, ebm-papst outlines some air purifier types. It goes on to explore radial fan and backward curved impeller advantages when used in conjunction with HEPA filters. It puts ECM technology’s benefits as “the modern motor design” in the same context for contractors and owners.

Comfort is the priority for the homeowner, Silvey observed, but the manufacturer and distributors emphasize that the company has also worked to maximize ease of installation for contractors, freeing up more time for more visits per day.

Hansen wrapped up his comments by recommending that contractors help homeowners understand that while there is more than one way to achieve variable speed control, those methods may come with differing degrees of technical and other repair/replacement support.

At the end of the day, Silvey said, COVID-19 has had an impact and will continue to do so for wholesalers and contractors who work to adapt.

“Customers are selling a great deal more IAQ equipment outside of our ECM products,” he said, but “the responsibility is on the suppliers to illustrate how central the motor is to the overall performance of IAQ.”

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment