Centralized heat production and cooling monitoring can be accomplished in multifamily and mixed-use office buildings with hydronic heat metering. As awareness of energy efficiency grows, building owners are finding that occupants who pay for their energy use seem to be inclined to reduce it in the long run. This, along with decreased equipment requirements and the increased potential for lesser maintenance costs, have some contractors looking into the nitty gritty of hydronic heat metering.

According to John Siegenthaler, principal at Appropriate Designs, Holland Patent, New York, any system that is hydronic based and where keeping track of energy or the rate of energy flow is needed, is a potential candidate for heat metering.

“One application that stands out in particular is any kind of multi-unit housing or office space, like an apartment building where you have multiple spaces that want to keep track of their energy use separately,” he said. “It’s much more efficient and lower cost to centralize the heating and cooling production and distribute it through the building. That can be done on many buildings, and it has been done. What hasn’t been done up until very recently is the ability to meter that heat.”

TECHNOLOGY AND STANDARDS

Although centralized heating/cooling production is not a new concept for hydronic applications, measuring the usage of that energy is where heat metering changes the game for contractors.

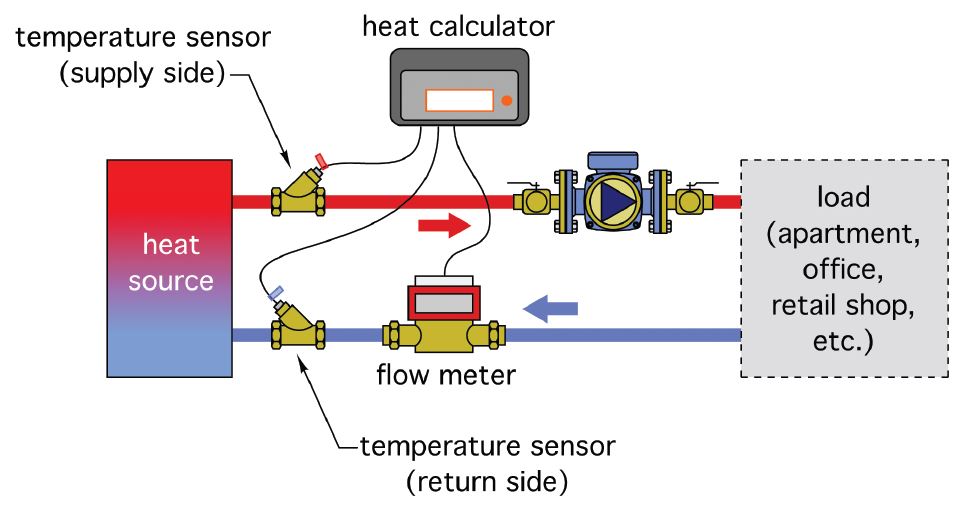

HEAT METERING CONCEPT: This diagram shows the concept of a heat source supplying heat to a load. The load can be an apartment, condominium, retail shop, leased office space, or an entire building.

“Heat metering requires a continuous and accurate measurement of the flow rate of water, or water/antifreeze solution, passing into and out of each building space,” Siegenthaler said. “It also requires a continuous and accurate measurement of the temperature change of that fluid, from the location where it enters the space to where it exits. The flow rate and temperature change measurements can then be mathematically combined to determine the instantaneous rate of heat transfer to that space.”

He presented on the topic during one of the free education sessions at the 2019 AHR Expo. In this presentation, he laid out the math and formulas that back the legitimacy of the information obtained from the hydronic system set up with heat-metering components. He further explained that the introduction of the ASTM E3137/E3137M-17 as the standard of accuracy used for heat-metering hardware in the U.S. served as a gateway to possibilty.

“This standard really set the market into play,” Siegenthaler said. “Prior to that standard being in place, there was really nothing that an engineer or an end user in the U.S. could reference as a standard of accuracy.”

SMART PRODUCTS AND BENEFITS

With standards in place and heat-metering practices pushing further onto the list of light commercial and commercial options, the hydronic sector is getting a boost in the industry according to Bob “Hot Rod” Rohr, training manager for Caleffi North America Inc., Hydronic Solutions.

“I feel we are in the midst of another hydronic golden era,” he said. “New products seem to be unveiled weekly, and corporate mergers are opening more access to unique and cutting-edge hydronic products and concepts from markets around the globe.”

The new products Rohr referenced are becoming smarter, he said. The microprocessor controls available to the industry are finding their way onto boilers, pumps, valves, thermostats, etc.

“It’s on everything but the pipe, it seems,” said Rohr. “The smart circulator pump technology and low-current-draw zoning components are getting the attention of the market, especially with the energy-conscious folks and design engineering community. Embrace the technology, it is not going away.”

From his vantage point, Rohr has seen that light commercial and commercial contractors are having success with installations using a single circulator-, zone-valve-based distribution system. He is also watching developing trends, like increased online monitoring, diagnostics, and tweaking of components in the commercial hydronic market. These advances in technology are allowing technicians to limit the time spent traveling to a customer’s facility by monitoring and adjusting the systems remotely.

Building owners are benefitting from the use of heat metering as well. Not only can they market to their customers that they only pay for what they use, but owners or tenants aren’t having to pay the fees for having several gas meters on the building.

HYDRONIC TRAINING

Increased demand, new standards, and smart products can provide opportunities for contractors that are currently working with hydronic installations, as well as those looking to become involved in the market. According to Siegenthaler, contractors in the hydronic market that want to start installing heat metering must first find a meter supplier and start a relationship with them.

“These meters are not hard to install,” he said. “It is basically one device that measures flow rate and two temperature sensors. These meters are simpler than a boiler in many respects, as far as putting them in.”

Despite the ease of installation, both Siegenthaler and Rohr emphasized that training is necessary.

“Book smarts is a good step for contractors,” Rohr said. “Learn the theory and formulas behind the technology.”

With book knowledge in hand, Rohr suggested that contractors shouldn’t spend all or most of their time searching for online advice and opinions, but they should also make an effort to gain hands-on experience in the field, finding a knowledgeable mentor who is willing to instruct and guide their progress.

Another hydronic training opportunity available to contractors is called Coffee with Caleffi™. This program is an educational series of webinars intended for contractors, designers, and wholesalers. The complimentary one-hour sessions are conducted by Caleffi personnel, including Rohr, and feature industry expert guest speakers like Siegenthaler.

“We started this program in 2010, and Caleffi feels webinars offer us the opportunity to reach a global audience at their convenience,” Rohr said. “The information we provide is at the fingertips of anyone that is connected, anywhere, at any time. This platform provides a very powerful mechanism to train and share from our wide array of industry presenters.”

All previous webinars are archived on YouTube and accessible 24/7.

Siegenthaler advised that contractors also get a free copy of the idronics™ publication from Caleffi’s website. There are currently 24 issues available.

“The idronics 24 issue introduces people to the idea of heat metering and shows them that heat metering has been used since 1949 in Germany, long before there were electronic heat meters,” he said. “There were electromechanical meters, and they were doing the same thing — measuring flow rate and temperature change, calculating the amount of thermal energy. Heat metering has been applied for several decades in the European and Asian markets, it’s just relatively new to North America.”

Publication date: 7/15/2019

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment