Customer demands for the HVAC industry are the same as they have always been. They are looking for comfort and cost-effectiveness. But they are also looking for ways to mitigate the spread of the coronavirus and help the environment. Hydronics offer ways to address all these factors.

For example, chilled beams along with a dedicated outdoor air system (DOAS) allow for increased ventilation while minimizing airborne particle distribution. They’re powered by outside air, but there’s no transference of air between adjacent spaces within a building, said Ken Watson, senior vice president of global marketing for Taco Comfort Solutions.

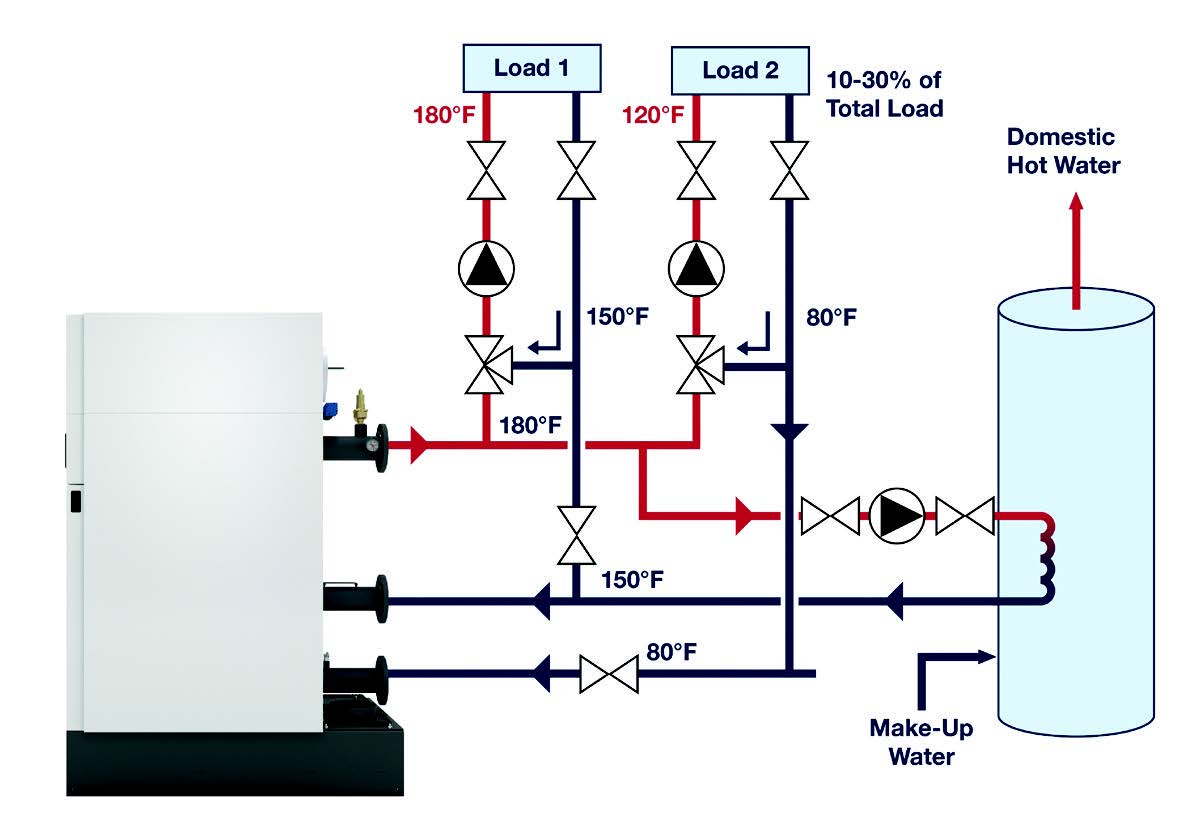

UNDER THE COUNTERTOPS: Consumers may pay more attention to visible home improvements, such as granite countertops, but instant hot water — such as provided by this Taco system — is a luxury itself. Courtesy of Taco

“It surprises some people, professionals among them, to find that many of the answers to the challenges posed by COVID-19 are out there and available — the know-how, expertise, and technology solutions,” Watson said. “Yet the solutions must be applied deliberately and with purpose, tailored to the benefit of people within interior spaces. “

Chilled beam systems also reduce the total amount of distribution air while increasing the amount of outside air. Distribution air is typically 80% less in a chilled beam system as compared to a conventional variable air volume (VAV) system. In many cases, this translates into using one-tenth as much fan horsepower for chilled beam distribution air versus a VAV system.

Improved Energy Efficency

That’s important because energy efficiency and environmental impact are also top considerations when investing in HVAC technology for either commercial or residential use. Catie Van Wormer, P.E., LEED AP, the engineering manager for packaged boiler systems at Cleaver-Brooks, said customers are replacing aging equipment and upgrading to condensing boilers for these reasons.

“Condensing boilers are typically more environmentally friendly than traditional boilers, and the added efficiency also helps to reduce total emission production,” Van Wormer said.

Mark Chaffee, Taco’s vice president of governmental affairs and C&I product management, said the ECM motor, which is now commonly available up to 30HP, has really changed the game in the pump market. Today’s ECM-based products consume up to 85% less electricity, but they can also enhance overall system efficiency and performance with the right controls attached.

Controls are now evolving quickly and are having a big impact on system operation and efficiency, Chaffee said. Installers now have the ability to look inside the pipe and see what’s happening in the system, directly from phone apps developed for the task.

One of the biggest issues for the hydronics segment has been that major problems can develop unseen. Technology is helping to address this challenge. Kolyn Marshall, systems engineering manager at Watts, said the most common trends in smart technology are leaning toward remote access. This can be for a thermostat, a snowmelt control, or even a boiler.

“Users want to see run-time data and have the ability to augment or change system operation, remotely,” Marshall said. “This can be as simple as a remote start/stop control or to avail more sophisticated options, such as changing target temperatures or run times.”

Click diagram to enlarge

ALWAYS INNOVATING: Hydronics products continue to move forward, such as this Cleaver-Brooks boiler system, a past finalist for an AHR Expo Innovation Award. Courtesy of Cleaver-Brooks

Innovation Versus Cost

Marshall said builders are often caught between the need to provide quality and innovation and the need to bring in a project at a reasonable cost. Many smart features, such as IoT devices, remain outside the mainstream and lack visibility among the end-consumers. That means they remain options, although that will change over time.

“It’s like automatic transmissions in cars,” Marshall said. “It used to be an option, and now it’s difficult to find a car or truck with a manual transmission.

“IoT is a lot like this. Eventually these features will become the standard — and expected, not optional.”

The biggest driver for the hydronics segment in 2021 will be new construction. Chaffee said talking with new home builders about hydronic and plumbing technology feels a lot like an HVAC installer talking to homeowners about humidification systems. Consumers can see other home features, such as granite countertops, the latest bathroom fixtures, and pendant lighting. The industry needs to create a connection in people’s mind between hydronics and whole-home performance.

“Our entry point may be our ability to substantially improve the performance of those high-end plumbing fixtures,” Chaffee said. “Having hot water recirculation (HWR) allows those luxurious fixtures to perform without compromise. Hot water recirculation saves time, water, and money. With HWR, impatient homeowners don’t have to wait for hot water at points of use.”

Water shortages in many parts of North America have homebuilders and their customers more interested in wasting less water, Chaffee said. A family of four typically wastes 12,000 gallons of water each year simply by waiting for hot water at the tap or shower. A new generation of smart recirc system technology “learns” a family’s water use patterns and keeps hot water at the tap for use at a moment’s notice, when it’s needed.

Supply And Demand

While demand has been a positive for the HVAC industry since the summer, supply has created some challenges. Van Wormer said she sees little effect from supply disruptions in the hydronics segment.

“While issues do arise when components are harder to get, our engineering and logistics teams have been able to work together to maintain the delivery of equipment to our customers on time to meet their needs,” she said.

Marshall said all supply chains and manufacturing have been impacted and complicated by COVID-related challenges, although the situation is improving.

On the demand side, Watson sees some areas of concern in the commercial market going forward, especially in hospitality and commercial officer construction/remodeling. Marshall said the building industry should be flat to slightly up over 2020, with the second half of the year seeing the largest gains. He said mindset will play as much a role as any other factor.

“The biggest impact is sure to come from people who refuse to give up or surrender their dreams,” Marshall said. “Our advice: build, manufacture, create.”

Report Abusive Comment