The thermostatic expansion valve (TXV) is a refrigerant metering device that constantly modulates and meters just enough liquid refrigerant from the liquid line into the evaporator to satisfy all heat load conditions on the evaporator. The TXV also simultaneously controls a set amount of evaporator superheat while, under these same conditions, assuming the range and capacity of the valve is not exceeded.

By controlling the evaporator superheat, TXVs keep the entire evaporator just full enough of refrigerant to enable higher net refrigeration effects. The TXV also prevents liquid floodback of refrigerant to the compressor by controlling evaporator superheat, which, in turn, ensures the presence of compressor superheat. TXVs do not control box temperature or compressor running time, nor do they cycle the compressor or control evaporator pressure.

OPERATING PRESSURES

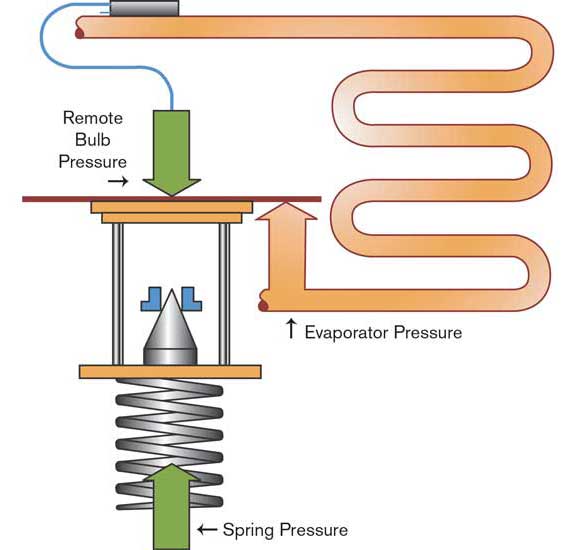

Figure 1 illustrates the three basic forces acting on a TXV: remote bulb pressure, evaporator pressure, and spring pressure. Notice that both the evaporator and spring forces are closing forces, while the remote bulb force is the only opening force. Let’s look at these forces individually.

FIGURE 1: The three basic forces acting on a TXV: remote bulb pressure, evaporator pressure, and spring pressure. PHOTO COURTESY OF SPORLAN DIVISION, PARKER HANNIFIN CORP.

Remote Bulb Pressure

The remote bulb of the TXV is clamped firmly to the suction line at the evaporator’s outlet for good thermal contact. The remote bulb is the TXV’s feedback mechanism that gives the valve an indication of what the evaporator superheat is. Remote bulbs come in a variety of charges for special applications (consult with the TXV manufacturer for specific information on remote bulb charges).

Pressure from the volatile fluid in the remote bulb acts on the top side of the flexible bellows through the connecting capillary tube (see Figure 1). This causes the valve to open as remote bulb pressure increases. This changing pressure in the remote bulb is caused by the evaporator outlet temperature getting hotter or colder from varying heat loads on the evaporator, which momentarily affects and changes evaporator superheat amounts. The higher the evaporator superheat, the more fluid that will vaporize in the remote bulb, causing higher pressures. The less the superheat, the more condensing of vapor that will take place in the remote bulb, thus decreasing its pressure and closing the valve. As soon as the TXV realizes that the evaporator superheat is changing, it will react and either open or close, putting more or less refrigerant into the evaporator from changing remote bulb pressures. This maintains a set amount of evaporator superheat.

Evaporator Pressure

As heat loads on the evaporator change in time, so does the rate of vaporization of the refrigerant in the evaporator. Higher heat loads cause higher rates of vaporization of the refrigerant in the evaporator, which will increase evaporator pressure. Lower heat loads on the evaporator will decrease the rate of vaporization of the refrigerant and decrease evaporator pressure.

Evaporator or suction pressure acts on the underside of the flexible bellows of the TXV (see Figure 1). This will cause the valve to close as the evaporator pressure increases. In fact, through a drilled passageway called the internal equalizer, evaporator pressure from the evaporator’s coils entrance acts on the underside of the bellows. This evaporator pressure opposes the remote bulb’s pressure. An internally equalized TXV is shown in Figure 2.

Spring Pressure

The spring pressure acts in the same direction on the bellows as the evaporator pressure. Spring pressure is a closing force, as seen in Figure 1. When the spring pressure and the evaporator pressure equal the remote bulb pressure, the valve is said to be in dynamic balance or equilibrium, and will neither open nor close until the evaporator heat loading changes. If the evaporator pressure rises or falls, the valve tends to open or close. Also, if the remote bulb pressure changes from changing evaporator heat loadings and evaporator superheat changes, the valve will open or close.

Spring pressure in most valves is preset by the OEM for a predetermined amount of evaporator superheat. This spring is often referred to as the superheat spring, since it is the only way a technician can change the amount of evaporator superheat in the system. Increasing the spring tension by turning the spring adjustment clockwise will tighten the spring. This, in turn, will give the TXV more closing force and cause the superheat setting to increase, which will give the system more operating evaporator superheat. There are some TXVs on the market whose superheat springs are nonadjustable and come with a set amount of superheat that cannot be changed by a technician. These TXVs are usually used in applications where superheat settings are critical for proper performance, as in some ice machines.

EXTERNALLY EQUALIZED TXVS

Large refrigeration systems have larger evaporators, which have more pressure drop due to longer piping lengths and more U-bends within the piping. These evaporators will need to use an externally equalized TXV to compensate for this pressure drop and to fill out the evaporator with the proper amount of refrigerant for the set amount of evaporator superheat.

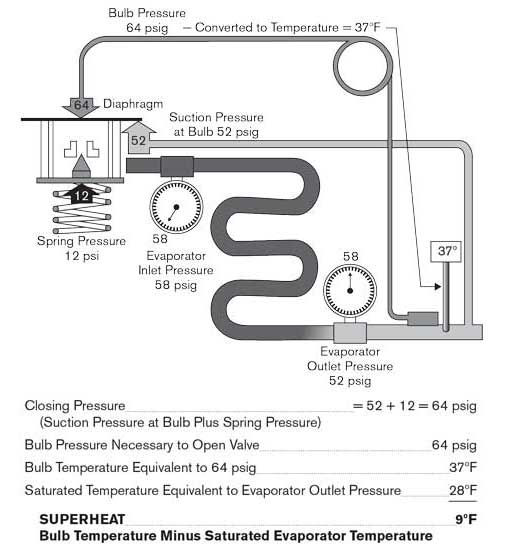

FIGURE 3: An externally equalized TXV with a sample superheat calculation. PHOTO COURTESY OF SPORLAN DIVISION, PARKER HANNIFIN CORP.

Externally equalized TXVs sense evaporator pressure at their evaporator outlets and not their inlet (see Figure 3). The evaporator pressure will be sensed very close to the remote bulb location, which will compensate for any pressure drops throughout the length of the evaporator. By sensing this smaller evaporator outlet pressure, there will be less pressure on the bottom of the TXV’s bellows than if evaporator inlet pressure were sensed as in an internally equalized TXV.

This lower pressure will be a smaller closing force; thus, the valve will remain more open and fill out more of the evaporator by compensating for the pressure drop through the evaporator.

The external equalizer does not get rid of pressure drop in an evaporator; it only compensates for it by sensing evaporator outlet pressure instead of inlet pressure. Figures 4 and 5 show flare- and sweat-type externally equalized TXVs, respectively. An externally equalized TXV is required whenever the pressure drop in the evaporator exceeds 3 psig (a/c applications); 2 psig (commercial refrigeration applications); or 1 psig (low-temp applications).

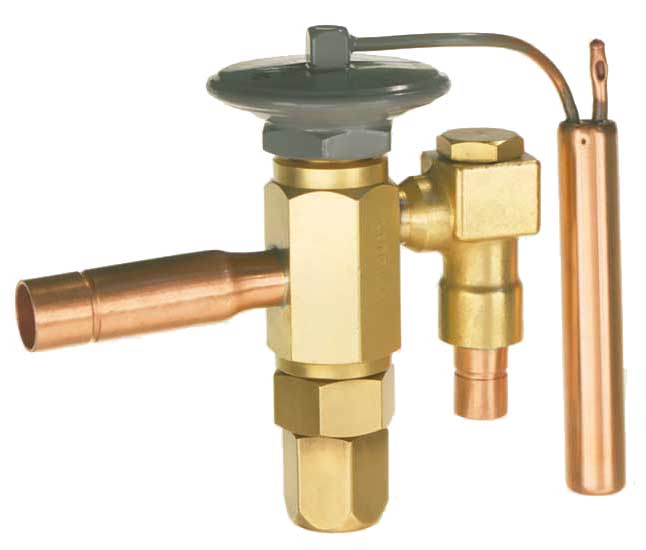

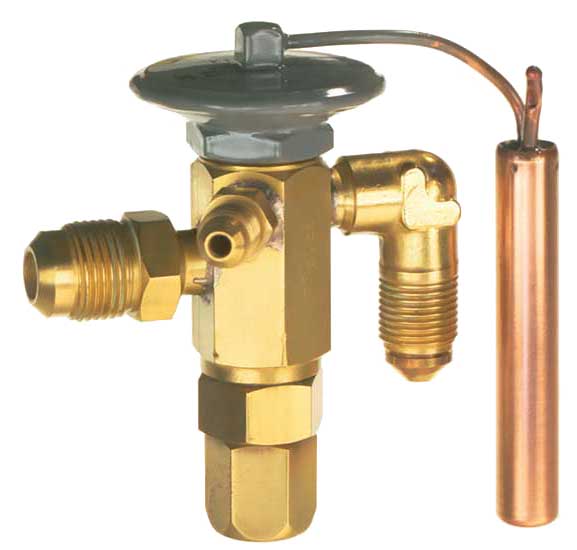

FIGURE 4: An externally equalized TXV with flare joints. PHOTO COURTESY OF SPORLAN DIVISION, PARKER HANNIFIN CORP.

FIGURE 5: An externally equalized TXV with sweat joints. PHOTO COURTESY OF SPORLAN DIVISION, PARKER HANNIFIN CORP.

For example: Figure 3 shows an R-22 externally equalized TXV system diagram. Because the evaporator is large and has noticeable pressure drop, the evaporator outlet pressure is sensed by the TXV through an external equalizer line tapped into the evaporator outlet. The TXV now sees an evaporator outlet pressure of 52 psig underneath its diaphragm. The evaporator superheat would be:

37°F evaporator outlet temperature (bulb temperature)

- 28°F saturated temperature (equivalent to evaporator outlet pressure)

= 9°F superheat

By no means should a service tech ever cap or close the external equalizer port of a TXV. If that happens, there would be no way for it to sense any evaporator pressure (closing pressure), and the valve would flood the evaporator and maybe even the compressor. The external equalizer line, which connects the TXV to the evaporator outlet, should also never be restricted, pinched, or closed off. When applied correctly, externally equalized TXVs will make the evaporator more efficient by ensuring the proper amount of evaporator superheat.

Publication date: 1/14/2019

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!